Metals like aluminum, magnesium, titanium, etc., have found applications in various industries ranging from automotive to aerospace, to electronics, etc., because of their desirable properties.

However, these applications require that these metals are deployed in harsh service conditions. These conditions include high humidity, high temperature, the presence of acids and salts in a service environment etc., causing these metals to lose their properties or parts. The result of this is the failure of these metals in service, resulting in a high cost of maintenance or component replacements.

Techniques have been deployed in order to protect these metals when deployed in these conditions. Anodizing is one of the techniques used to preserve these metals from harsh conditions in service. It helps to improve the durability of these metals, thereby reducing the cost of maintenance and replacement of components.

In this article, we’ll review what anodizing is, the materials used, and how the process actually works.

Key Takeaways

- Anodizing is an electrochemical process that converts the metal surface into a decorative and durable anodic oxide finish to protect the metal from harsh conditions.

- Aluminum, magnesium, and titanium are commonly used metals in the anodizing process due to their high affinity for forming a stable oxide layer.(1)

- Anodizing is used in a wide range of industries, including business aviation, commercial aviation, defense, medical/life sciences, and space and communication systems.

What Is Anodizing?

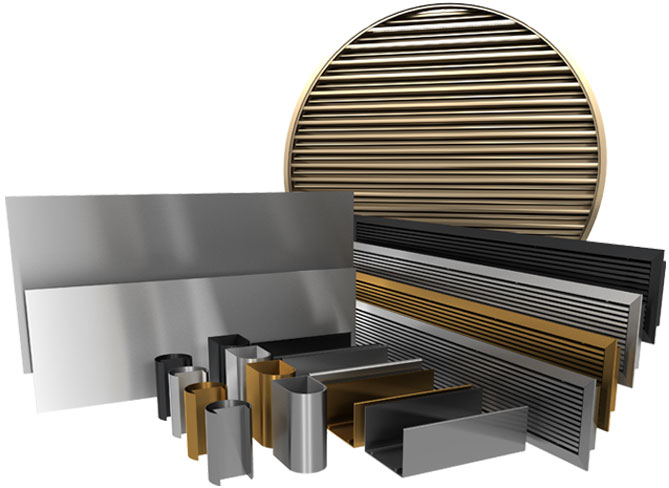

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Although other nonferrous metals, such as magnesium and titanium, can also be anodized, aluminum is best suited for the process. The anodic oxide structure, made completely of aluminum oxide, comes from the aluminum substrate.

This aluminum oxide is totally integrated with the underlying metal substrate rather than being applied to the surface like paint or plating, making it resistant to chipping and peeling. In addition, its well-organized porous structure enables further procedures like coloring and sealing.

Aluminum is anodized by dipping it into an acid electrolyte bath and then running an electric current through it. The anodizing tank has a cathode mounted inside of it; aluminum serves as the anode, causing oxygen ions to be released from the electrolyte and combined with aluminum atoms on the surface of the component being anodized. Therefore, anodizing is the enhancement of a naturally occurring phenomenon through carefully controlled oxidation.

What Is Anodizing Used For?

Anodizing is a low-cost, high-quality finishing method. As a result, it is widely used in a number of applications across numerous sectors. Its applications are so varied that chances are you utilize an anodized metal component every day.

- Aerospace

- Automotive

- Architecture

- Consumer goods

- Homeware sectors

What Materials Can Be Anodized?

Below is a list of materials that can be anodized including:

Aluminum

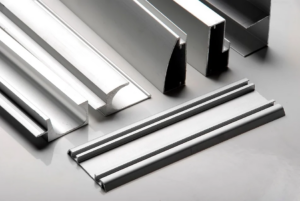

The most common materials to be anodized are aluminum and aluminum alloys. Because of its high strength-to-weight ratio and relative availability, aluminum is utilized extensively in industrial operations. Aluminum’s overall performance is enhanced, and its useful life is increased by anodizing. There are numerous distinct aluminum anodizing procedures.

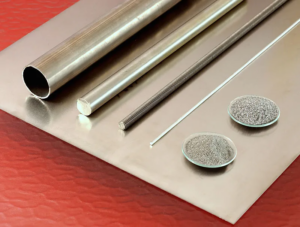

Magnesium

Magnesium is typically anodized for use as a paint primer, and for this application, thin coatings (as little as 5 m) are adequate. Magnesium materials can have their corrosion resistance improved by having anodic coatings that are thicker (25 m or more). For best results, these coatings need to be sealed with sodium silicate, wax, or oil.

The following specifications are applicable for magnesium anodizing: AMS 2466, AMS 2478, AMS 2479, and ASTM B893.

Titanium

The jaw, hip, and knee implants are frequently made of anodized titanium. In addition, anodized titanium is popular for art, costume jewelry, body piercing jewelry, and wedding bands because the anodizing technique may produce various hues without using dyes. The oxide layer’s thickness, ranging from 30 nanometers to several micrometers, affects color. The anodizing voltage, in turn, controls thickness.

AMS 2487 and 2488 are applicable standards for anodized titanium.

Niobium

Similar chemicals and procedures to anodizing titanium can be used on niobium. By altering the coating thickness, which is also reliant on anodizing voltage, a variety of colors can be produced. Costume and body jewelry, commemorative coins, and other highly attractive objects are frequently made of anodized niobium.

Tantalum

needs to be anodized using a method similar to that of titanium and niobium. By adjusting the film thickness, a variety of appealing colors can be created. Depending on the chemical solution employed and the process temperature, the voltage needed to anodize tantalum typically ranges from 18 to 23 Angstroms per volt. The most popular type of tantalum used to make capacitors is anodized tantalum.

Zinc

The process of anodizing zinc can be challenging. When used with voltages as high as 200V DC, a mixture of ammonium phosphate, chromate, and fluoride can create anodized coatings up to 80 m thick on zinc alloys, enhancing their hardness and corrosion resistance.

Zinc-plated steel components can be anodized utilizing chemical baths comprising sodium silicate, sodium hydroxide, borax, sodium nitrate, and nickel sulfate at lower voltages (20-30V DC).

MIL-A-81801 is one of the applicable specifications for anodized zinc.

Types Of Anodizing Processes

Below is a list of the types of anodizing processes including:

Type I: Anodizing

Commonly known as chromic acid anodizing, is a popular method that coats the metal substrate with an oxide layer.

Chromic acid anodizing, the thinnest of the three primary anodic coating methods, produces an electrically non-conductive surface with enhanced scratch and corrosion resistance.

Type I is the preferred procedure for aerospace and other industrial components that may bend due to heat changes or mechanical means since the resulting oxide layer is thin.

Pros

- Corrosion protection

- Non-conductive / electrical insulation

- Improved dielectric strength

- Lesser absorption of pigmentation

- Appropriate for parts with tight tolerances

- Accepts a higher degree of flexion

Type II: Sulfuric Acid Anodize

The most used anodizing technique is type II anodizing, often known as sulfuric acid anodize. A protective coating of aluminum oxide is created by altering the surface of an aluminum substrate material.

It is best suited for situations where hardness and abrasion resistance are necessary.

Additionally, sulfuric acid anodize can be used as a foundation for paint systems or to increase surface corrosion and protection under demanding operating circumstances. In particular, the fabrication of colorful surface finishes on aluminum, and related alloys take advantage of the porous character of sulfuric acid coatings before sealing.

Pros

- Corrosion protection

- Abrasion resistance

- Increased hardness

- Improved Thermal or electrical insulation

- Increased lubricity

- A much thinner coating compared to paints or powder-coat finishes

- The dimensional build-up often can be ignored for machined parts

Type III – Hardcoat Anodize

Type III aluminum anodizing, also known as hard coat anodizing or hard anodizing, is used to improve the thermal and dialectical properties of treated aluminum products and their wear and corrosion resistance. In addition, with Type III anodizing, the capacity to retain lubricants and PTFE coatings (such as Sanford HardlubeTM) also improves.

The thickness of the naturally existing oxide layer on aluminum surfaces is increased through hard coat anodizing. With Type III anodizing, natural oxide layers’ thickness, typically 2 to 3 nanometers, can be raised to or even above 50 m* (0.002″). A very regular, uniform layer is produced across the whole surface of the treated object by properly placed hard anodic coatings.

The military standard Mil-A-8625 Type III category gave rise to the abbreviation Type III anodizing. * μm = micrometer (1000x the length of a nanometer).

Benefits of Anodizing Aluminum

Some of the benefits of anodizing aluminum include:

Durability

The majority of anodized items have extraordinarily long lifespans and provide significant financial benefits due to maintenance and operational cost savings. For complete bonding and unrivaled adhesion, anodizing is a reactive finish that is merged with the underlying metal.

Color Retention

The majority of anodized items have extraordinarily long lifespans and provide significant financial benefits due to maintenance and operational cost savings. For complete bonding and unrivaled adhesion, anodizing is a reactive finish that is merged with the underlying metal.

Simple Maintenance

There are hardly any scars or wear from fabrication, handling, installation, routine surface dirt cleaning, or use. An anodized surface may typically be cleaned with mild soap and water or rinsed to bring back its original appearance. For harder deposits, you can use mild abrasive cleansers.

Aesthetics

Anodizing decreases or completely removes color inconsistencies while providing a vast array of gloss and color options. In addition, anodizing, unlike other finishes, enables aluminum to keep its metallic appearance.

Cost

Greater long-term value is produced by a lower initial finishing cost combined with lower maintenance expenditures.

Safety and Health

Anodizing is a harmless technique that has no negative effects on health. Anodized finishes are non-toxic, stable chemically, won’t break down, and can withstand heat up to the melting point of aluminum (1,221 degrees F.)

The anodizing process is non-hazardous and has no toxic or dangerous byproducts because it strengthens a naturally existing oxide reaction.

Disadvantages Of Anodizing Aluminium

- Only certain grades of aluminum are suitable for this technique,

- Stainless steel, which is resistant to mortar, salt, chlorine, and marine environments, cannot be utilized with this product.

- This process draws from the base metal, allowing for color changes.

- In low-grade metals, no match is achievable across batches, making consistency between batches more difficult to recreate than in high-grade metals where a 95% match is possible.

- The priciest option for modest quantities (requires a higher-grade alloy in addition to the already high set-up costs).

Anodizing In Aerospace

In close succession to the original sulfuric acid anodizing (SAA) procedure, which was first patented in 1927, Bengough and Stuart’s chromatic acid anodizing (CAA) was the first commercial anodizing method.

In the middle of the 1950s, the Japanese invented oxalic acid. Today, the main focus is on using sulfuric acid as a supplementary acid in hard coat anodizing (HCA) to create a tougher coating more quickly than with a pure sulfuric acid electrolyte.

The Boeing Company developed both phosphoric acid anodizing (PAA) and boric sulfuric acid anodizing (BSAA), the former as a structural bonding surface and the latter as a substitute for CAA for non-critical fatigue parts. The sulfuric acid anodizing procedure is the one that is most frequently employed; however, for aerospace purposes, things look a little different.

Chromic Anodizing

Chromic acid anodizing is mostly used to safeguard crucial joints and structures. The corrosion resistance is very good for the coating’s thickness, which is typically between 0.08 and 0.2 mils. The oxide film is generated without any major material fatigue loss and is softer and less porous than those created by the other techniques. The hue is a pale opaque gray, and the film is easily destroyed. This film takes on a greenish hue when it is sealed with a dichromate seal.

Depending on the kind provided, the procedure is voltage controlled, starting with a ramping increase up to 40 volts. The military specification MIL-PRF-8625F specifies two types: type I and type IB. Type I produces conventional coatings at a voltage of about 40 volts, whereas Type IB operates at a voltage of 20 to 22 volts.

Sulfuric Acid Anodizing

Type II coatings and Type III coatings are the two categories into which sulfuric acid anodizing falls. Hard coat oxide films, Type III, are utilized for engineering purposes, such as the aerospace sector, whereas Type II is usually employed for ornamental or protective applications.

According to MIL-PRF-8625F, Type III coatings are those created by electrolytically treating aluminum and its alloys to create a consistent anodic coating. As long as a thick, dense coating is formed, this offers variety in the process operations methods.

The resultant hard film is very dependent on the aluminum alloy used. Higher current densities and lower electrolyte temperatures were used in the initial procedures. With higher copper alloys from the 2000 series—some of the preferred alloys for the aerospace industry—these process parameters provide some challenges. As a result, significant effort has been made to lessen these challenges.

One of the key alterations has been the addition of oxalic acid to the sulfuric acid electrolyte. Additionally, new electrical sources, pulse techniques, and variations in electrolyte temperature have been devised.

Phosphoric Acid Anodizing

In high-humidity conditions, phosphoric acid anodizing is primarily employed for structural adhesive bonding. This process is known as the Boeing Process and is carried out at 10-15 V. When exposed to harsh conditions, the produced oxide film is more durable than films made in chromic acid and sulfuric acid. The morphology of the oxide film, which should be a film of pores with whiskers or protrusions on the top surface of the produced film, is claimed to be one of the causes of the excellent adhesive property.

The last anodizing process mentioned is the new boric sulfuric acid. The chromic acid electrolyte, which includes hexavalent chromium, can be replaced with this. Because it causes cancer, hexavalent chromium must be phased out of metal finishing procedures. Hexavalent chrome-free electrolytes are therefore required. The paint adhesion of the oxide film produced by the boric sulfuric electrolyte is on par with or better than that of the film produced on chromic acid. Voltage control is used, and the process is ramped up to 15 V. To achieve an adequate level of corrosion resistance, a seal in a hot, diluted chromate solution is needed.

Anodizing Process Steps

The anodizing process requires a few steps including:

Pre-Treatment

Before you anodize a part, you have to prepare its surface through mechanical and chemical means. To give your part the desired aesthetic, polish or bead blast the surface first. While brushing will give your part a brushed appearance, bead blasting will give it a natural matte finish.

The chemicals you employ before anodizing will affect how glossy your product turns out. For instance, etching will give your item a satin finish that is smooth. You should choose bright dipping or chemical polishing for a glossy finish.

Rinsing

Remove contaminants, such as machining waste like lubricants and coolant, from the item by rinsing it in deionized water and other solvents. To remove the metal’s surface layer, submerge the washed components in a solution of sodium hydroxide (NaOH) and nitric acid (HNO3). This procedure is not necessarily required if the item has already been mechanically treated.

To stop an anodizing surface from forming in certain sections of a part, you can mask such areas.

Etching (Chemical Milling)

Sodium hydroxide solution is often used for alkaline etching.It gives the metal’s surface a light-gray satin gloss (through a diffuse reflection of the incident light). This pre-treatment method is used for the vast bulk of jobs.

The amount of sodium hydroxide solution present, the temperature, and the number of aluminum ions discharged into the solution all affect how quickly an object etches. The solution becomes ineffective when aluminum ions are present in large proportions. Other ions may be present, some of which may be an alloy component, interfering with the process and leaving flaws on the work’s surface.

By using etching solutions that inhibit the action of the released Al3+ and other metal ions, the issue of ion contamination is solved. These solutions’ ingredients are proprietary to the businesses that create them, although they typically include sequestering agents that contain complex metal ions. These solutions don’t have an endless capacity to do this, but because the etched work “carries over” the solution and is periodically replaced by a new etch solution, the etching batch is kept in an efficient condition.

The etching solution also contains foaming agents, which work to lessen the strong fumes and mists that emerge from the intense reactions. It’s vital to remember that at this point, the final product’s appearance is decided. No matter how well the piece is anodized or tinted, improperly etched work will show scratches or flaws.

Acid Desmutting

The aluminum develops a “smut” coating as a result of etching. The grey-to-black smut is the insoluble alloy residue left over after the aluminum has been etched away. A nitric acid solution is most frequently used to remove this smut, leaving a prepared surface ready for anodizing.

Anodizing

Place the component(s) in the anodization bath while the electrical circuit still powers it. The solution’s composition, temperature, current density, voltage, and time are just a few examples of the parameters that can change depending on the desired attributes mentioned above.

Coloring

During anodizing, you can regulate the color of the component. Depending on the oxide coating’s thickness, the visible spectrum’s nanometer-sized wavelengths can reflect light in various ways. Various colors are produced using various parameters.

Put your part in a solution of metallic salts to give it a bronze or black polish. These interact with the surface to fill the pores with a chemical substance that is either black or bronze. It is known as electrolytic coloring.

Dip coloring, which fills the pores with a dye solution, might be used if you desire a different color. Place your component after dipping it in the dye in warm DI water to stop any additional reactions. Dip coloring is the least resilient of the coloring techniques described here since the color may deteriorate over time if exposed to UV light.

Sealing

To stop future corrosion and boost performance, you must seal the tiny pores on the component’s surface after anodizing. Anodized parts may feel tacky to the touch if the pores are not sealed. Additionally, dirt, pollutants, and stains can gather in open pores.

There are three common processes for sealing pores:

Hot DI Sealing

With this technique, you submerge the component in deionized water that has been heated to nearly boiling. Boehmite, or hydrated aluminum oxide, is created when the water reacts with the component. Compared to aluminum oxide, boehmite fills the pores and takes up more space.

It is straightforward to standardize this procedure. It can, however, result in dye bleed and color leakage on dyed materials and has a significant energy cost.

Mid-Temperature Sealing

This technique, which uses metal salts in a solution like salts of nickel, magnesium, or cobalt to react with the surface and fill the pores, requires less energy than heat sealing.

This technique lessens sealing smut or surface mineral deposits and is preferable for colored components. However, it’s more challenging to control and challenging to repeat with the same accuracy.

Cold or Room-Temperature Sealing

Cold sealing chemistries frequently use nickel-fluoride formulations that interact with the porous aluminum oxide layer to generate a sealed fluoro-aluminate layer that is then deposited on the surface.

The surface is etched during this process to improve performance and adherence. Additionally, it complies with a few automotive and military standards. It can be slow, though, and may need a hot water bath to hasten the curing process, making it more difficult to manage.

How To Know If The Anodizing Process Was Successful

There are many ways to tell if a part has undergone anodizing. Below are some useful ways you can employ.

Examine For A Matte Finish

The matte sheen that anodizing produces usually makes it clear.

Make Use Of A Basic Scratch Test

Scratch the aluminum component’s surface with a coin. If a scratch is apparent, the component was probably merely polished rather than anodized. An anodized component will have complete scratch resistance.

Dispersal Of Color

An even surface with color dispersion is the product of a successful anodizing procedure. Watch out for anodizing burns brought on by high current densities and insufficient agitation during the anodizing process as anodizing faults on your finished product.

Aluminium Anodizing Services

Valence offers every variety of anodizing, including but not limited to:

Type I Anodize

- Boric Anodize – Boric-Sulfuric Acid Anodize (BSAA) is an alternative to chromic acid anodize (CAA), which builds a thin-film anodic coating and provides corrosion protection and a mechanical bond. This is an environmentally friendly solution.

- Tartaric Anodize – Tartaric-Sulfuric Anodize (TSA) is an alternative to chromic acid anodize (CAA), which builds a thin-film anodic coating and provides corrosion protection and a mechanical bond. This is an environmentally friendly solution – typically specified in Airbus programs like the A350.

- Chromic Anodize – Chromic Acid Anodize (CAA) creates the thinnest anodic while providing the same corrosion resistance as other types of anodization, such as boric or sulfuric.

Type II

- Sulfuric Anodize – Sulfuric Acid Anodize (SAA) is used when hardness and abrasion resistance is required and creates a surface that is harder than traditional chromic anodizing.

Type III

- Hard Anodize – Hardcoat anodize is created from a sulfuric acid bath, but results in a much thicker surface anode coating than traditional sulfuric acid anodizing.

Phosphoric Acid Anodize

- Phosphoric Acid Anodize – Phosphoric Acid Anodize (PAA) is most commonly used in bonding applications, providing a superior porous surface for bonding to composites.

Please contact us with any questions about our anodizing process or request a quote today.

Conclusion

Now that you know more about anodizing aluminum, you can decide whether or not this process is right for your parts. You can also reach out to our valence team if you need help deciding.

If your business needs functional aluminum parts that will face corrosion or wear, such as aircraft parts or consumer goods, contact us, and we’d be more than happy to help.

Sources:

- Anodizing. Anodizing – an overview | ScienceDirect Topics. (n.d.). https://www.sciencedirect.com/topics/engineering/anodizing#:~:text=Aluminum%2C%20magnesium%2C%20and%20titanium%20can,and%20part%20of%20the%20metal.

- Electroplating for decorative applications: Recent trends in research … (n.d.-a). https://www.researchgate.net/publication/326589071_Electroplating_for_Decorative_Applications_Recent_Trends_in_Research_and_Development.

- Author links open overlay panelI. Tsangaraki-Kaplanoglou a, a, b, c, d, AbstractIn this paper specimens of pure aluminum, Mrowka_Nowotnik, G., Perovic, A., Crossland, A. C., Habazaki, H., Fratila-Apachitei, L. E., Ibl, N., Amirikas, R., Rauhala, E., Tsangaraki-Kaplanoglou, Serebrennikova, I., Tachihara, K., Adrews, D. G., Barnes, C., & Jelinek. (2006, July 7). An investigation of electrolytic coloring process of anodized aluminum coatings. Surface and Coatings Technology. https://www.sciencedirect.com/science/article/abs/pii/S0257897206004270#:~:text=Electrolytic%20coloring%20uses%20an%20ac,electrolytic%20coloring%20electrolytes%20%5B4%5D.

FAQs

What is the limitation of anodizing?

The limitation of anodizing is primarily related to the types of materials that can be effectively anodized. Aluminum is the most commonly anodized material, while other metals, such as steel or copper, may have limited success with the process.

What is the purpose of anodizing?

The purpose of anodizing is to increase the corrosion resistance and wear resistance of metal surfaces. It also provides a decorative finish that can be used to create aesthetically pleasing products.

How can we improve the anodizing process?

The anodizing process can be improved by optimizing parameters such as voltage, current density, and electrolyte composition.

Additionally, using high-quality anodizing equipment and implementing proper surface preparation techniques can enhance the overall outcome.

Can anodizing be applied to various metals?

Yes, anodizing can be applied to a variety of metals including, aluminum, magnesium, and titanium.(1)

Does anodizing affect the surface finish?

Yes! Anodizing can affect the surface finish of a material. It does so by modifying the surface texture and appearance of the material.

Does anodizing affect dimensions?

No, anodizing typically does not significantly affect the dimensions of the material being anodized. The process adds a layer of oxide on the surface, which is usually very thin and does not alter the overall dimensions of the metal.

However, it is important to consider the buildup of the oxide layer when applying anodizing to tight tolerance parts, as it may impact the fit or assembly of the components.

Is anodizing magnetic?

No, anodizing is not magnetic. The anodizing process does not change the magnetic properties of the metal.

Does heat affect anodizing?

Yes, heat can affect the anodizing process. High temperatures can impact the thickness and quality of the anodized coating.

How does anodizing affect material properties?

Anodizing can affect material properties by increasing the hardness and durability of the surface. It also improves the corrosion resistance of the metal.

Does anodizing fade over time?

No, anodizing does not fade over time. The anodized coating is integral to the metal surface and provides long-lasting color and protection against fading.

However, exposure to harsh environmental conditions or prolonged UV exposure may gradually degrade the appearance of the anodized finish over an extended period.