Chemical Processing

We offer a complete suite of Nadcap and AS9100 approved chemical processing services across the United States.

Valence technicians are experts in aerospace wet processes, ensuring a flawless finish on all your parts. We offer processing for various alloys, including aluminum, steel, titanium, and nickel-based alloys. Our alloys are made up of carefully combined elements to optimize toughness, corrosion resistance, and ductility.

With state of the art processing lines, we have the most diverse set of anodize capabilities which include tartaric-sulfuric anodize, boric-sulfuric anodize, chromic, and hard anodize. Our process ensures efficiency in a wide range of applications.

Valence also offers unique capabilities such as phosphoric-acid anodize and phosphate fluoride sol-gel for titanium. We are the leaders in chemical processing for Boeing and Lockheed, with over 4,500 unique processing approvals for other suppliers such as Airbus, Bombardier, and Safran. We continually serve and exceed the standards of the top names in the aerospace industry.

Chemical Processing Services

Anodizing

Type I Anodize:

- Boric Anodize – Boric-Sulfuric Acid Anodize (BSAA) is an alternative to chromic acid anodize (CAA), that builds a thin-film anodic coating and provides corrosion protection and a mechanical bond. This is a chromated, environmentally friendly solution.

- Tartaric Anodize – Tartaric-Sulfuric Anodize (TSA) is an alternative to chromic acid anodize (CAA), that builds a thin-film anodic coating and provides corrosion protection and a mechanical bond. This is a chromated, environmentally friendly solution – typically specified in Airbus programs like the A350.

- Chromic Anodize – Chromic Acid Anodize (CAA) creates the thinnest anodic coating, while providing the same corrosion resistance as other types of anodization, such as boric or sulfuric.

Type II Anodize:

Type III Anodize:

Phosphoric Anodize

- Phosphoric Acid Anodize (PAA) is most commonly used in bonding applications, as it provides a superior porous surface for bonding to composites. It serves as a strong adhesive in high-humidity environments.

Chemical Film or Chem-Film

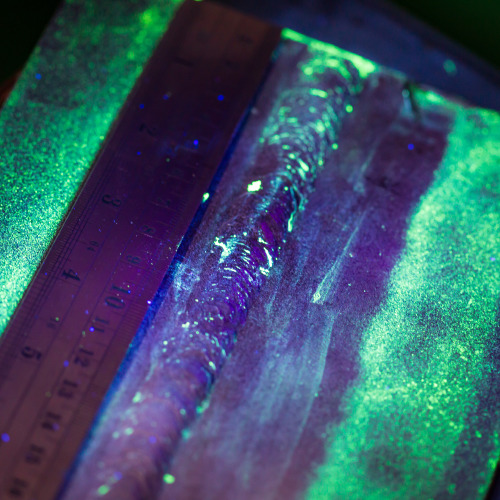

Nital Etch

- Nital etch is a solution of nitric acid and alcohol, used to etch metals. Nital etching is used to detect overtempering, improper carburization, and re-harding, as well as other manufacturing errors.

Phosphate Fluoride

- Phosphate fluoride coating is used to inhibit corrosion, improve paint adhesion and to reduce damage in metal to metal contact applications. In addition, phosphate fluoride can be used in etching solutions, namely for titanium.

Aluminum Etch

- Aluminum etch is a process by which a thin layer of the surface is removed, prior to penetrant inspection, typically in caustic or alkaline baths or solutions. This enhances the identification of surface defects, prior to further processing.

Zinc Phosphate

- Zinc Phosphate is a conversion coating for steel and aluminum, comprised of phosphate salts and phosphoric acid. This coating resists corrosion and allows for adhesion.

Chemical Processing Tank Sizes – Aluminum

| Valence Eastman | L | Valence Wichita | L | Valence Grove | L | Valence Garden Grove | L | Valence Los Angeles | L | Valence Seattle | L | Valence Everett | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Anodize - Boric Sulfuric | 19.5' | Anodize - Boric Sulfuric | 12' | Anodize - Boric Sulfuric | 24' | Aluminum Etch (Pickle) | 15' | Anodize - Boric Sulfuric | 27' | Anodize - Boric Sulfuric | 6' | Anodize - Boric Sulfuric | 30' |

| Anodize Phosphoric (PAA) | 8' | Anodize - Tartaric Sulfuric | 12' | Anodize - Type I Chromic | 24' | Anodize - Type II Sulfuric | 11' | Anodize - Tartaric Sulfuric | 27' | Anodize - Type II Sulfuric | 6' | Anodize - Type II Sulfuric | 12' |

| Anodize - Type I Chromic | 19.5' | Anodize - Type I Chromic | 12' | Anodize - Type II Sulfuric | 24' | Anodize - Type III Hard Coat | 11' | Anodize - Type I Chromic | 27' | Chemical Film - Type 1 (Bonderite 1200) | 6' | Anodize - Type III Hard Coat | 12' |

| Anodize - Type II Sulfuric | 19.5' | Anodize - Type II Sulfuric | 12' | Anodize - Type III Hard Coat | 24' | Chemical Film - Type 1 (Iridite 14-2) | 11' | Anodize - Type II Sulfuric | 27' | Chemical Film - Type 1 (Bonderite 600) | 6' | Chemical Film - Type 1 (Alodine 600) | 30' |

| Chemical Film - Type 1 (Chromicoat L25) | 20' | Anodize - Type III Hard Coat | 8' | Chemical Film - Type 1 (Alodine 1200S) | 24' | Chemical Film - Type 1 (Alodine 1500) | 10' | Anodize - Type III Hard Coat | 27' | ||||

| Chemical Film - Type 1 (Alodine 1132) | touch up pen | Chemical Film - Type 1 (Alodine 1600) | 12' | Chemical Film - Type 2 (Alodine 1500) | 8' | Chemical Film - Type 1 (Alodine 600) | 5.5' | Chemical Film - Type 1 (Alodine 1200S) | 27' | ||||

| Chemical Film - Type 2 (Chemeon TCPHF) | manual application | Chemical Film - Type 2 RoHS Compliant | 42' | Chemical Film - Type 1 (Alodine 1500) | 3' | ||||||||

| Chromate Treatment | 2' |

Chemical Processing Tank Sizes – Hard Metals

| Valence Eastman | L | Valence Wichita | L | Valence Grove | L | Valence Garden Grove | L | Valence Los Angeles | L | Valence Seattle | L | Valence Everett | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Passivation Type I, II, III | 3' | Nital Etch | 4' | Inconel Etch | 3' | Passivation type ll | 6' | Passivation Type II | 6' | Passivate Type II | 6' | Passivation Type II | 12' |

| Passivation Type VI | 4' | Passivation | 4' | Passivation Type II, VI, VII, VIII | Call | Passivation type ll, Vl, Vll, Vlll | 2' | Passivation Type VI | 4' | Passivate Type VI | 6' | Passivation Type VI | 12 |

| Titanium Etch (Pickle) | 22' | Phosphate Fluoride | 10' | Phosphate Fluoride | 8' | Titanium Etch (Pickle) | 2' | Phosphate Fluoride | 10' | Phosphate Fluoride | 4' | ||

| Titanium Etch (Pickle) | 10' | Titanium Etch (Pickle) | 24' | Titanium Etch (Pickle) | 27' | Titanium Etch (Pickle) | 4' | ||||||

| Zinc Phosphate | 3' | Titanium Etch (Pickle) |

What Is Zinc Phosphate Coating?

Zinc phosphate is a conversion coating for steel and aluminum, comprised of phosphate salts and phosphoric acid. This coating resists corrosion and allows for adhesion. In fact, zinc phosphate dental cement has been used widely for crowns, bridges, and orthodontic appliances as well.

However, a zinc phosphate coating first begins as a crystallized coating (a powder first) and then after a chemical reaction, the metal and the phosphate form to create the final coating. This means that metals coated with zinc phosphate then have high corrosion resistance.

What Is The Difference Between Zinc And Zinc Phosphate?

Zinc phosphate is an inorganic compound that comes in a white powder formulation. Before the use of zinc phosphate, there were other toxic materials in place. However, by 2006, zinc phosphate replaced lead and chromium to be the most commonly used corrosion inhibitor.

Zinc is often used in these processes due to its rust-preventing properties. While zinc phosphate may be a popular coating type, zinc has been used for years on iron and stainless steel products. Depending on the type of coating, zinc acts as a barrier against corrosion. Many call this the zinc patina as it becomes the barrier between a stainless steel product and the elements.

What Is Zinc Phosphate Coating Used For?

It is used to prevent corrosion. This is done by providing strong adhesion and protection against corrosion. A zinc phosphate coating may be used in: construction, drilling, mining, refineries, and transportation among others.

What Is The Zinc Phosphate Coating Process?

The process begins by treating the metal with a zinc phosphate solution, which then creates a surface layer of crystals – this is what protects the metal underneath from corrosion. This layer can either contain finer or heavier crystalline phosphates, which often depends on the method of application.

Application Methods – [H3]

- Immersion Process – This is the most common method with a heated bath. This means that you put the item(s) in the bath with the coating and let the electrochemical process occur

- Spray Process – The spray process is another method of application, but it must be done with care to avoid any pickling or other imperfections.

How Thick Should The Zinc Phosphate Coat Be?

While this will range depending on the material, the coating thickness generally ranges from 0.0002 inches to 0.0006 inches.

Benefits Of Zinc Phosphate Coating

Zinc phosphate is a non-conductor but has a variety of benefits to consider including:

- Strong Primer – You can add a zinc phosphate coating as the first treatment layer to provide corrosion resistance for: paints, oils, waxes, and Chemical Agent Resistant Coating (CARC)

- Strong Adhesion & Protection – A zinc phosphate coating provides a strong adhesive and corrosive protection against rust. This also provides better friction for sliding components/parts

- Withstands Many Conditions – As a Chemical Agent Resistant Coating (CARC) used in the military, zinc phosphate coatings provide protection from the harshest of environments

Disadvantages Of Zinc Phosphate Coating

Heating phosphates can be difficult to get right, but many of the conceived disadvantages just come down to perfecting the process. Some must deal with a lack of phosphate crystal growth, which is what is responsible for creating that strong outer coating. And others may deal with “acid pickling” issues which usually boils down to cleaning and rinsing properly.

However, for more on how we go about the zinc phosphate coating at Valence, contact us today and we’ll explain the process from start to finish.

How Long Does Zinc Phosphate Coating Last?

As it is built to last, a zinc phosphate coating should be able to hold up to a lot. The corrosion resistance and insolubility in water makes it a great choice for high wear applications. Similarly, the melting point of a zinc phosphate coating is 1,650 F which makes it able to stand up to high temperatures as well.

Is Zinc Phosphate Coating Rust Proof?

In general, phosphate coatings are protective against rusting and corrosion. However, much of this depends on proper application because these coatings can be porous when applied.

Zinc Phosphate Coating Services

Metal finishing can be daunting – there’s the cost associated and the application methods to consider. However, with nine centers across North America, at Valence, we serve a global supply chain with the most comprehensive set of processing capabilities and approvals for high-value, mission-critical parts.

Our zinc phosphate coating service is widely used for commercial aviation and military and defense clients as well as a wide range of other industries. For more on us and our process, get in contact with us today and we’ll chat you through any upcoming projects you may have.

Chemical Processing News

Explaining the Differences Between Hardcoat and Other Anodizing Methods

Anodizing has revolutionized the durability and aesthetic appeal of metallic objects as a prominent surface treatment technology. Within the realm of anodizing, different methodologies exist, each presenting unique advantages and applications. One such methodology...

An Overview Of Titanium Anodizing And Its Applications In Aerospace

Within the dynamic realm of aerospace engineering, where precision, durability, and optimal performance are paramount, the ceaseless pursuit of innovation remains a guiding force. Amidst the array of transformative technologies that have revolutionized the industry,...

Choosing The Right Finish: Anodizing Vs. Powder Coating

Choosing the appropriate finish for a project, such as anodizing or powder coating, can present quite a challenge. Both of these finishes have distinct advantages and considerations, making it crucial to fully grasp their unique characteristics to guide your...

Understanding The Benefits Of Titanium Anodize For Corrosion Control In Aerospace

The use of titanium has continued to gain more traction in various industries around the world, all thanks to its excellent corrosion resistance and relatively high strength-to-density ratio. Having been embraced by aerospace industries for the development of...