About us

Our Mission: to be the most trusted partner in aerospace surface finishing.

Valence Surface Technologies is a full-service surface finishing company specializing in the commercial aerospace, defense, space and satellite industries. With ten strategically located sites across the United States, Valence provides a start to finish solution from NDT and chemical processing, to paint and sub-assembly.

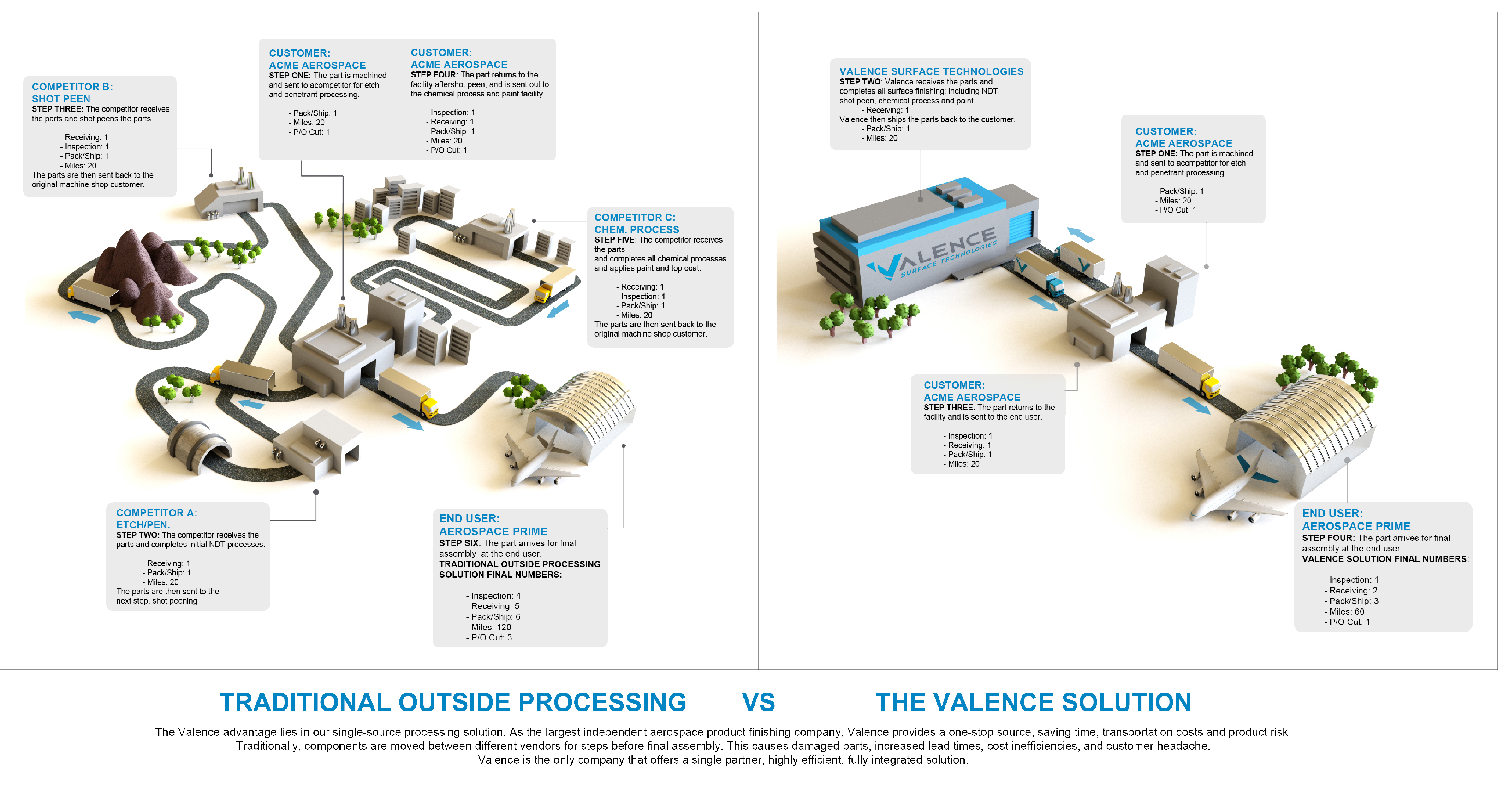

Traditionally, the aerospace supply chain has been a fragmented system comprised of many different suppliers completing a different step of the chain. One company may be responsible for the initial inspection and shot peening, and then another anodizes, while another has responsibility for the paint, and so on and so forth. These processes may take place spread across the country, at great cost due to unnecessary lead time, inventory, risk, and management resources.

Valence exists to change the supply chain. By providing an all-inclusive solution in every region of the country, we reduce cost, the amount of suppliers, the distance parts must travel, lead times, while maintaining the capacity to grow with new programs. We do this by maintaining over 4,500 approvals, for every prime and program in existence today.

Valence is the world’s largest independent aerospace surface finishing company. We are unique in that we are the only complete integrated solution in the supply chain, saving time and money for our customers. With our nationwide locations, we have the capacity to grow with you as your business does.

Many may know our various locations by their legacy names, including: Coast Plating in Los Angeles, CA, Coastline Metal Finishing in Garden Grove, CA, Tri-Process in Paramount, CA, MAPSCO in Seattle, WA, Bluestreak Metal Finishers in Everett, WA, Pride Plating in Grove, OK, Dynamic Paint Solutions in Eastman, GA, Chrome Plus International in Wichita, KS, and Fountain Plating Company in West Springfield, MA. With a combined 300+ years of experience, you can count on Valence for the guidance and expertise to have your parts finished right.

Global Partner of Choice

The Aerospace Product Finishing Industry’s Most Trusted Partner

Full Service; Industry Leading; Investing for Growth; Delivering Productivity

UNMATCHED breadth of capabilities with core services that include Nondestructive Testing (NDT), Shot Peening, Chemical Processing, Plating, and Spray Coatings.

With over 4,500 unique approvals, we offer the MOST COMPREHENSIVE special processing capabilities for high-value, mission-critical parts, no other company matches our capacity and global reach.

With 12 facilities comprising over 750,000 sq ft of manufacturing space located in key global aerospace manufacturing hubs, we service over 3,000 global customers supporting EVERY MAJOR commercial, military, missile, UAV, space and satellite program in North America, Europe and Asia.

SIGNIFICANT CAPITAL investments in capacity and technology that improve productivity, reduce supply chain costs, enhance lead time, mitigate risk and lead to greater customer value, all while providing lead edge environmental stewardship and compliance.

Facilities

Square Feet

Employees

Global Customers

Approvals

Parts Per Month

Valence… THE ANSWER to the long-standing Aerospace Industry challenges of an overly complex and highly inefficient supply chain, driven by supplier fragmentation, restricted capital access, lack of innovation and lackluster environmental stewardship.

Valence is the Future

Before Valence

After Valence

Over the Last Decade

Valence is the clear exception. As the world’s largest, independent aerospace product finishing company we have:

• We focus on ease of doing business by offering a collaborative, solutions-oriented culture focused on the highest level of quality and customer service

• We remain intensely focused on our core competencies and centers of excellence approach to offer the most comprehensive set of special processing cabilities and most

• We simplify things for our customers by using a common, best-in-class quality management system to ensure performance, reduce risk and apply best practices across the enterprise.

• We invest in capacity expansions, greenfield facility builds, new technologies and capabilities within our existing locations to ensure we stay at the forefront of the aerospace industry’s product finishing needs.