Choosing the appropriate finish for a project, such as anodizing or powder coating, can present quite a challenge. Both of these finishes have distinct advantages and considerations, making it crucial to fully grasp their unique characteristics to guide your decision-making process. In this article, we will delve deep into the defining attributes, strengths, and limitations of both anodizing and powder coating, assisting you in making an informed, effective choice.

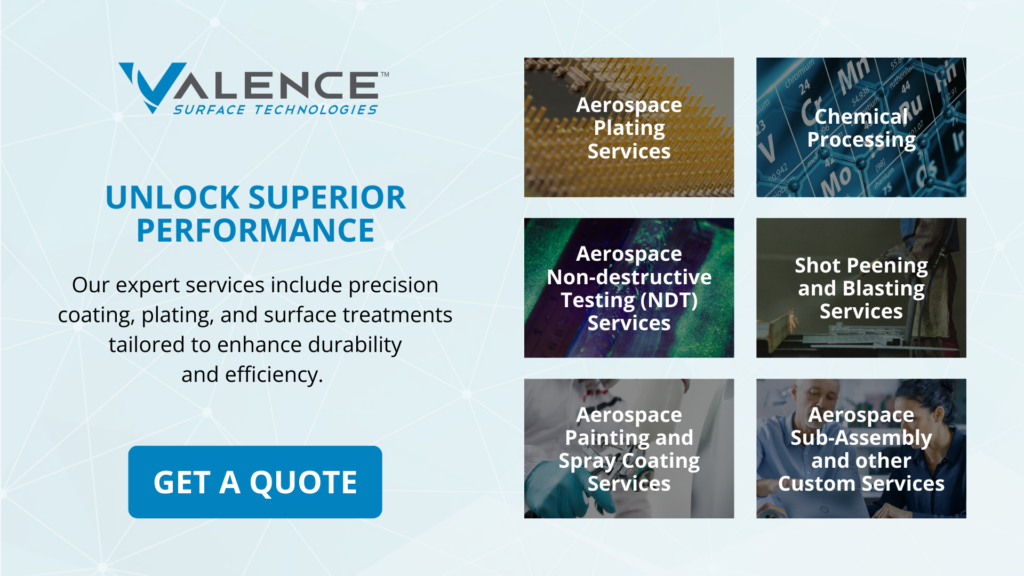

After reading, if you’re ready to explore more or need personalized advice for your project, don’t hesitate to visit us at Valence Surface Technologies or reach out to us and learn more about our services. At Valence, we’re committed to supporting your project’s success every step of the way.

What Is Anodizing?

Anodizing is an electrochemical process that forms a protective oxide layer on metal surfaces, shielding them from corrosion and wear. By submerging the metal in an electrolyte solution and passing an electrical current through it, oxidation is induced, creating this protective layer.

The process is adjustable, allowing for the customization of the oxide layer’s thickness and properties by altering the voltage, current, and electrolyte type. This technique enhances not only the durability and corrosion resistance of the metal surfaces, but also their aesthetic appeal, and fosters better adhesion for other coatings like paints and dyes.

How Does Anodizing Work?

Anodizing works through an electrochemical process where metal surfaces are immersed in an electrolyte solution. An electrical current is then applied, initiating the formation of a protective oxide layer on the metal. This enhanced layer significantly boosts the metal’s durability, corrosion resistance, and aesthetic appeal.

Metals such as aluminum, titanium, and magnesium commonly undergo this process. The anodizing method is favored for its numerous benefits, including increased wear and abrasion resistance, improved corrosion resistance, decorative finishing, and stronger adhesion for paints and coatings.

It is frequently utilized in the automotive and marine sectors due to these attributes. An additional advantage of anodizing is that it is economical, swift, straightforward, and environmentally friendly, as it neither produces hazardous waste nor utilizes dangerous chemicals.

Why Should You Consider Anodizing?

Here are reasons why you should consider anodizing:

Harder Than Powder-Coated Surfaces

Anodized surfaces are tougher than powder-coated ones, due to the oxide layer created through anodizing, which is both harder than aluminum and more scratch-resistant. Thus, anodizing is ideal for applications necessitating a durable, uniformly finished surface.

Cannot Peel Off

Anodizing is an electrochemical process that creates a durable oxide layer on metals, like aluminum, through a chemical acid bath. This process enhances the strength of the metal and produces a pleasing metallic appearance. The resulting oxide layer is strong and cannot be peeled off easily.

More profound, Richer Metallic Appearance

Anodizing yields a deeper, richer metallic look than powder coating as it makes the coating part of the aluminum itself. The process, involving the reaction of aluminum with an electrolyte, results in a sealed aluminum oxide layer that provides a more aesthetically pleasing and durable finish.

Unaffected By Sunlight

Anodizing creates a corrosion and wear-resistant protective layer on metals, enhancing their aesthetic appeal with a richer metallic appearance. Unaffected by sunlight and resistant to UV radiation, it doesn’t fade or discolor, making it ideal for outdoor projects exposed to harsh elements.

Anodized Coating Process

The anodizing process employs a unique electrolytic technique to form a robust, protective oxide layer on an aluminum surface. Here is a brief process of anodized coating:

- Surface Preparation: The process starts with an in-depth preparation of the aluminum surface, effectively removing any traces of dirt, debris, or oils that might be present.

- Electrolyte Bath: Post-cleaning, the surface is immersed in an electrolyte solution, typically a solution based on sulfuric acid.

- Electrical Current Exposure: The surface then undergoes exposure to an electrical current. This step is vital as it triggers the binding of oxygen molecules to the aluminum, forming a protective oxide coating.

The thickness of the oxide layer relies heavily on the duration of the aluminum’s exposure to the electrical current and the voltage applied. Notably, higher voltage results in a thicker oxide layer. This oxide layer is then sealed with a coating, enhancing the surface’s resistance to corrosion and wear.

Equipment You’ll Need For Anodizing

Embarking on the journey of anodizing requires specialized equipment and safety gear. Here’s a comprehensive guide to what you’ll need:

- Anodizing Tank (Rectifier): The heart of the anodizing process, this piece of equipment controls the electrical current passed through the aluminum surface, fostering the formation of the protective oxide layer.

- Water Tank: A water tank is crucial for the rinsing process post-anodization.

- Degreaser: This ensures the aluminum surface is clean, oil-free, and ready for anodizing.

- Rinsing Tank: A rinsing tank comes into play for thoroughly washing the aluminum surface after the degreasing process.

What Is Powder Coating?

Powder coating is a dry finishing process widely popular since its North American introduction in the 1960s, representing over 15% of the total industrial finishing market. It involves applying a free-flowing, dry powder—typically a thermoplastic or thermoset polymer—to a surface, followed by heating to create a hard, durable finish tougher than conventional paint.

Primarily used on metals such as aluminum and steel, this process provides both functional protection and decorative enhancements. It boasts a broad spectrum of colors and textures, superb performance properties due to technological advancements, and it is more durable than traditional liquid paints.

How Does Powder Coating Work?

Powder coating works using a process where polymer resin systems, along with other additives, are melted, cooled, and ground into a uniform powder. This powder is then applied to a metal substrate using electrostatic spray deposition (ESD), which employs a spray gun that applies an electrostatic charge to the powder particles, attracting them to the grounded part. The coated parts are then placed in a curing oven where, upon heating, the coating chemically reacts to produce highly resistant, long molecular chains.

Additionally, powder coatings can be applied via a fluidized bed application where preheated parts are dipped into fluidizing powder, which then melts and flows on the part. Regardless of the method used, powder coating is simple to apply, environmentally friendly, cost-effective, and robust.

Why Should You Consider Powder Coating?

Powder coating is a popular finish for aluminum and metal surfaces due to its durability and versatility. It offers several advantages over traditional liquid coatings, including:

Uv Resistant

Powder coating is a great option for surfaces that need UV resistance. It involves applying dry powder to the surface and then heating it at high temperatures. This creates a strong protective barrier that can withstand UV rays and offers excellent durability and corrosion resistance. Powder coating is particularly well-suited for outdoor surfaces.

Less Expensive

Generally speaking, powder coating is more cost-effective than anodizing since it requires less time, energy, and expensive materials. Anodizing, on the contrary, requires specialized, costly equipment, making powder coating a more economical choice for finishing aluminum projects.

Less Noticeable

The less conspicuous finish of powder coating is often preferred. Applied as a dry substance and then heat-cured, it creates a matte finish that reflects less light than anodized surfaces. Available in diverse colors, powder coating allows for finishes that seamlessly blend with their surroundings.

Powder Coating Process

With its minimal setup time, straightforward process, and cost-effectiveness, powder coating finds utility in a broad range of applications.

- Pre-treatment: To prepare the surface for powder coating, a chemical cleaner is used to effectively eliminate dirt, oils, and other contaminants. This thorough cleaning process guarantees a pristine surface, free from any impurities.

- Pre-Heating: Next, the metal is preheated to approximately 400 degrees Fahrenheit. This step primes the metal surface, facilitating the proper adhesion of the powder coating.

- Application of Powder Coating: The powder coating is then applied using an electrostatic gun, which uses an electrical charge to draw the powder onto the metal surface. Consequently, the powder melts and solidifies on the surface.

- Curing: The powder-coated metal is now ready for curing in an oven. Again, the temperature is set around 400 degrees Fahrenheit, and the metal is heated for a predetermined duration.

- Cooling and Inspection: After the curing process, the coating is allowed to cool and then inspected meticulously for any defects or imperfections. Should any be found, the powder coating is reapplied, and the process repeats.

- Final Product: Once the powder coating passes the inspection, it is considered ready for use.

Equipment You’ll Need For Powder Coating

Proper powder coating of aluminum surfaces necessitates specific pieces of equipment. Here’s a breakdown of what you’ll need:

- Powder Coating Gun: A handheld device used to apply the powder onto the aluminum surface. The gun typically features an attached nozzle that sprays the powder evenly across the surface.

- Oven: This is where the powder is baked onto the aluminum surface. It’s essential that the oven is spacious enough to house the entire aluminum part being coated.

- Curing Oven: The curing oven comes into play post-powder application. This oven should be capable of reaching at least 400 degrees Fahrenheit to adequately cure the powder-coated aluminum part.

- Powder Coating Booth: A roomy space where the powder coating process occurs. A powder coating booth needs to be well-ventilated for safety reasons and properly lit to ensure visibility during the process.2

Anodizing Vs. Powder Coating

Among the various finishes available, anodizing and powder coating are widely used in industries ranging from automotive to aerospace. To make a well-informed decision, it is essential to grasp the significant differences and benefits of each finish.

Surface Finish

Both anodizing and powder coating offer valuable methods of finishing surfaces, each with unique pros and cons. Anodizing involves the use of an electrolyte solution and electricity to create a protective oxide layer on metals, primarily aluminum, and magnesium alloys, enhancing their hardness and resistance to corrosion. Powder coating, on the other hand, employs a resin-based dry powder applied and heated on metal surfaces to form a corrosion-resistant coating.

Color Options

In terms of color options, both anodizing and powder coating delivers broad ranges. Anodizing allows the dyeing of the protective coating into any color, perfect for automotive parts, architectural components, and consumer electronics that need specific colors. Similarly, powder coating utilizes color pigments mixed with the dry powder to create a wide array of hues, applied and heat-cured for a smooth finish.

Corrosion Resistance

When evaluating corrosion resistance, anodizing edges out powder coating. The protective layer formed during anodizing effectively prevents oxidation, and its resistance can be boosted with an extra sealant. While powder coating provides reasonable resistance against corrosion, it isn’t as robust as anodizing, and it can be susceptible to chemicals.

Durability

In the durability showdown, anodizing holds the upper hand. This process forms an oxide layer on the metal that is highly resistant to wear, corrosion, abrasion, and UV rays, making it excellent for outdoor applications. Powder coating also creates a durable finish, but its thin layer is more prone to chipping and peeling compared to anodizing, despite its UV resistance and suitability for outdoor use.

Ready to take your project to the next level with expert finishing solutions? Don’t wait another moment! Reach out to us now. At Valence Surface Technologies, we’re eager to hear from you, and we’re committed to providing top-notch guidance and services for your unique needs. Let’s create extraordinary results together!

Check out: Anodizing Aluminum: Types, Benefits, And Process Explained

How To Choose Between Anodizing And Powder Coating

When deciding between anodizing and powder coating, several factors come into play: the cost of operation, durability, desired surface finish, necessary equipment, and color preference.

Anodizing is a pricier option due to its specialized equipment and complex process. However, it provides excellent resistance to corrosion, making it highly durable for outdoor applications. Anodizing produces a hard and matte finish, and it offers a wide range of colors through incorporated dyes.

On the other hand, powder coating is a cost-effective and efficient choice. It requires simpler tools like a spray gun, a compressor, and a curing oven. Powder coating results in a glossy finish that is resistant to UV rays. However, it is less resilient in outdoor conditions compared to anodizing.

Additionally, the color range of powder coating is achieved by mixing pigments, which may be limited to basic colors. If you desire more vibrant hues, there might be additional costs involved. Ultimately, the decision should align with the specific requirements and budget of the project.

Maintenance For Powder Coating And Anodizing

Maintaining the longevity and integrity of both powder-coated and anodized finishes demands proper and regular upkeep, despite their inherent durability.

For powder coating, the central tenet of maintenance involves regular surface cleaning. Employing a soft cloth paired with a mild detergent will efficiently serve this purpose. It’s crucial to steer clear of abrasive materials or harsh chemicals that might potentially harm the powder coating.

Similarly, anodized finishes demand upkeep using a mild detergent solution.3 Once again, the usage of abrasive materials or harsh chemicals can potentially mar the anodized finish. Additionally, exposure to extreme temperatures or caustic substances should be avoided as they can lead to premature wear of the anodized surface.

Valence Surface Technologies Expert Advice: Anodizing Vs. Powder Coating – Make The Right Finish Choice!

Choosing the perfect finish between anodizing and powder coating can be daunting, but with Valence Surface Technologies, you’ll never have to worry. Our experts at Valence bring years of experience and a wealth of knowledge, helping you make the right choice for your project’s finish.

We provide detailed advice and recommendations, ensuring the optimal selection between anodizing and powder coating based on your specific requirements.

At Valence, we are committed to offering you the best solutions, guiding you through every step to guarantee the highest quality finish and the most satisfactory results. Choose Valence Surface Technologies, where making the right finish choice is made easy and efficient.

Final Thoughts

When it comes to choosing the right finish for your project, anodizing and powder coating are two of the most popular options. Anodizing provides a harder, richer-looking surface that is resistant to corrosion and unaffected by sunlight. It is also more expensive and requires specialized equipment. Powder coating is a less expensive option that is UV resistant and offers a wide range of color options. Both processes require regular maintenance to keep the surface looking its best.

The choice between anodizing and powder coating doesn’t have to be a complex one. With Valence Surface Technologies, you’ll be armed with expert advice to make the perfect decision.

Ready to start your journey with us? Don’t hesitate to Request a Quote or contact us. At Valence, we’re eager to help you navigate your project with ease and confidence.

Gain more insights with some of our highly informative blogs:

- Anodizing Types: A Comprehensive Comparison Of Type II Vs Type III Anodizing

- Anodized Finishes: Types, Uses, And Benefits

- Understanding The Benefits Of Titanium Anodize For Corrosion Control In Aerospace

FAQs

Which aluminum finish should you choose?

The right aluminum finish for your project depends on the type of look and level of durability you need. Anodizing offers a more permanent, harder finish that won’t peel off, while powder coating provides a more decorative finish that is UV-resistant and less expensive. Consider the cost of operation and the type of surface finish required to make the best choice.

Can you apply powder coating over anodized aluminum?

Yes, you can apply powder coating over anodized aluminum, but it is not recommended. Powder coating over anodized aluminum can create a surface that is not as durable or as resistant to corrosion as anodized aluminum.

Does anodizing weaken aluminum?

No, anodizing does not weaken aluminum. Anodizing actually strengthens the aluminum surface by increasing its corrosion and wear resistance.

Why is anodized aluminum better?

Anodized aluminum is better than regular aluminum because it has a harder, more durable finish that is resistant to corrosion, wear, and sunlight. Anodizing also creates a richer, more profound metallic appearance.

Can you powder coat over anodizing?

Yes, you can powder coat over anodizing, but it is not recommended. Powder coating over anodized aluminum can create a surface that is not as durable or as resistant to corrosion as anodized aluminum.

SOURCES:

- What is Powder Coating? – Powder Coating Institute. (2019). Powdercoating.org; The Powder Coating Institute. https://www.powdercoating.org/page/WhatIsPC

- News, R. (2020, December 9). A Beginner’s Guide To Powder Coating Equipment Systems | Tutorial. Reliant Finishing Systems. https://reliantfinishingsystems.com/a-beginners-guide-to-powder-coating-equipment/

- John. (2023, February 4). Powder Coating vs Anodizing: Which is Better? – MellowPine. Mellowpine.com. https://mellowpine.com/blog/powder-coating-vs-anodizing/#:~:text=Powder%20coating%20and%20anodizing%20both