The performance of parts is crucial, particularly in the aerospace sector, where standards are extremely high. Manufacturing aerospace components is difficult due to the high stress, corrosive environments, long-term use of parts, and the requirement to produce parts to industry standards. Research and development (R&D) can use electropolishing to make sure prototypes pass rigorous inspections and testing before going into production. Electropolishing, most importantly, enhances part performance and aids aerospace manufacturers in adhering to industry standards. In this article, we will discuss what electropolishing is, how it works, and why it is important for aerospace applications. We will also discuss the benefits of electropolishing and the possible problems that can arise when using this process.

What Is Electropolishing?

Electropolishing is a metal finishing process used to improve the surface finish and corrosion resistance of metal parts. It is an electrochemical procedure that produces a smoother, brighter, and more corrosion-resistant surface by carefully removing material from a metal part’s surface. A direct current is run through the metal component that is submerged in an electrolyte solution to electropolish it. As a result, the metal surface undergoes an oxidation-reduction reaction that removes material. Additionally, the surface brightens due to the current, improving its aesthetic appeal. The process of electropolishing is often used for parts that require a high degree of cleanliness and corrosion resistance, such as aerospace components. It is also used for medical and food processing applications, as well as for decorative metal parts. Overall, electropolishing is a versatile and precise metal finishing process that can be used to improve the surface finish and corrosion resistance of metal parts. It is especially well-suited for aerospace applications, where cleanliness and corrosion resistance are paramount.

How Does Electropolishing Works?

Electropolishing is an electrochemical process that is used to polish and passivate metal surfaces. The procedure entails running a direct current through the metal component while immersing it in an electrolyte solution. A chemical reaction that results from the current’s action on the metal and electrolyte removes surface material and yields a polished, smooth finish. The first step in the procedure is cleaning the metal component to get rid of any debris, contaminants, or oils. After that, an electrical current is applied while the component is submerged in an electrolyte solution. The metal and the electrolyte solution interact electrochemically as a result of the electrical current. Through this reaction, metal ions are removed from the part’s surface, giving it a polished, smooth finish. The process is controlled by adjusting the current and the time of exposure. The current and time of exposure can be adjusted to remove a specific amount of material from the surface. This allows for a precise finish that can be tailored to the specific needs of the application.

Who Uses Electropolishing?

Many industries, including aerospace, automotive, medical, and food processing, use electropolishing. Electropolishing is a technique used in the aerospace industry to increase the corrosion resistance and surface finish of metal components. Burrs and other surface flaws are eliminated, friction is decreased, and the part’s overall appearance is enhanced. Several metals, including aluminum, stainless steel, titanium, and copper alloys, are subjected to electropolishing. Additionally, it is applied to a variety of parts, such as airframes, landing gear, and engine parts. Electropolishing can provide a uniform finish without harming parts, which is especially advantageous for those that are delicate or have complex designs. Electropolishing is also used in the medical industry to create medical instruments and implants that are both corrosion-resistant and aesthetically pleasing. Electropolishing can also be used to remove contaminants from medical instruments and implants, ensuring that they are safe for use in the body. In the food processing industry, electropolishing is used to create food-grade surfaces that are safe for human consumption. Electropolishing is also used to improve the appearance and durability of food processing equipment, such as tanks and conveyors. Overall, electropolishing is used in a variety of industries to improve the surface finish and corrosion resistance of metal parts. It is particularly beneficial for fragile or complex parts, as it can provide a uniform finish without damaging the part.

Why Is Electropolishing Important In Aerospace?

Because parts for the aerospace industry must be highly corrosion resistant and have a smooth surface finish, electropolishing is a crucial process. Extreme pressures and temperatures, as well as the effects of weather, salt water, and other environmental factors, must all be withstood by aerospace components. Electropolishing can help to extend the life of the component by creating a smooth, corrosion-resistant surface that is more resistant to wear and tear. Because electropolishing can help to reduce friction between parts, which can help to reduce wear and tear and improve the efficiency of the part, it is also important for aerospace components. Due to its ability to produce a brighter, smoother surface and a more uniform finish, electropolishing can also help to enhance the part’s aesthetics. Additionally, electropolishing can help to eliminate surface flaws like pits and scratches, which can enhance the performance of the component overall.

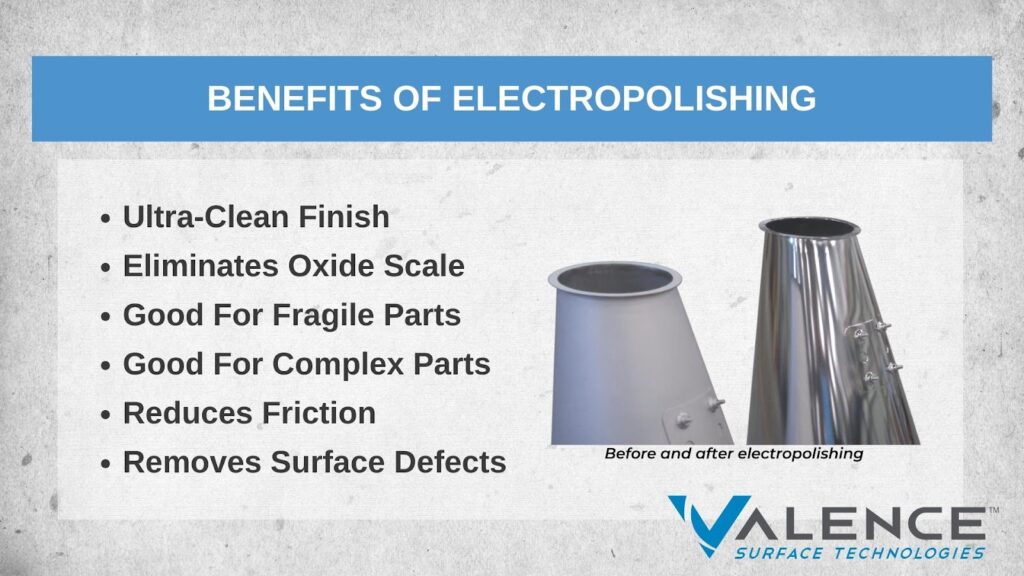

Benefits Of Electropolishing

Ultra-Clean Finish

The aerospace industry employs the electropolishing process to enhance the surface quality and corrosion resistance of metal components. This method is very good at producing an extremely clean finish, which is crucial for aerospace components. Electropolishing, as the name suggests, involves using electricity to polish the surface of a metal component. As it removes surface flaws and produces a smooth finish more effectively than mechanical polishing, this procedure is frequently used as a substitute. In electropolishing, metal ions from the part’s surface are removed using an electrolyte solution. Acid, salt, and water are combined in this electrolyte solution to aid in the dissolution of the metal ions. The procedure involves running an electric current through the electrolyte solution to remove the metal ions from the component’s surface. Surface flaws, burrs, and other imperfections can be effectively removed using this process, leaving behind a smooth, ultra-clean finish.

Eliminates Oxide Scale

On metal surfaces, oxide scale is a type of corrosion that can happen, especially in aerospace applications. Oxidation results in oxide scale, which can lead to a variety of issues, including decreased performance and increased wear and tear. Thankfully, electropolishing is a successful method of getting rid of oxide scale. The method cleans the metal’s surface of the oxide layer, leaving it smooth and corrosion-free. Due to the surface’s improved smoothness, this process also contributes to a reduction in friction and wear and tear. Your metal parts can perform at their best and remain in excellent condition by electropolishing.

Good For Fragile Parts

One of the many advantages of electropolishing in the aerospace industry is that it is good for delicate parts. Using electrical current, the surface material of metal parts is removed during the electropolishing process, leaving behind a smoother, corrosion-resistant surface. Due to the low levels of heat and pressure applied, this process is perfect for delicate parts. The likelihood of the part breaking or being damaged is decreased by the low heat and pressure levels. In order to achieve a smoother finish, burrs from delicate parts can also be removed using electropolishing. Because it can increase the surface finish and corrosion resistance without endangering the part, electropolishing is a fantastic option for delicate parts.

Good For Complex Parts

For complex parts, electropolishing is the best method because it can produce a more uniform finish than other techniques. The method provides a more consistent finish than alternative techniques because it can reach small crevices and recesses. The life and dependability of the part may be increased by reducing friction between the parts, which is another benefit of this uniform finish. Any surface flaws, such as burrs and other imperfections, which can be challenging to remove with other techniques, can also be eliminated by electropolishing. Since this method uses no abrasives and is therefore gentle, it is also suitable for delicate parts.

Reduces Friction

One of the key advantages of electropolishing for aerospace applications is the reduction of friction. An electropolishing procedure can lessen friction between two surfaces by removing microscopic flaws from the surface of metal parts. Longer service life, better performance, and increased fuel efficiency can result from this. The procedure produces a surface finish that is smoother and devoid of microscopic burrs and other surface flaws that might increase friction.

Removes Surface Defects

Metal parts can effectively have surface flaws like scratches, pits, and other imperfections removed using electropolishing. The process works by passing an electric current through the component, which induces a controlled dissolution of the metal. As a result, the surface finish is smoother and more consistent. The procedure also eliminates burrs or sharp edges that might have developed during the manufacturing process, as well as any oxide scale that may have accumulated on the part. The finished product has a much smoother surface finish and is more resistant to corrosion. Electropolishing is perfect for aerospace applications because it can also be used to lessen friction between two metal surfaces.

Possible Problems When Electroplating

Electroplating is a complex process and can be prone to a number of problems. The most common issues are related to the surface preparation, the electrolyte bath, and the electroplating process itself.

Surface Preparation

Surface preparation is essential for a successful electroplating process. If the surface is not properly cleaned and prepped, the electroplated layer will not adhere properly and can cause issues such as blistering, flaking, and corrosion.

Electrolyte Bath

The electrolyte bath is the solution in which the metal parts are submerged during the electroplating process. The composition of the bath must be carefully monitored to ensure that the electroplating process is successful. Improperly balanced electrolyte baths can lead to issues such as uneven plating, poor adhesion, and corrosion.

Electroplating Process

The electroplating process itself can also lead to problems such as poor adhesion, uneven plating, and poor corrosion resistance. Poorly designed equipment, incorrect power supply settings, or inadequate process control can all lead to issues. In order to ensure a successful electroplating process, it is important to use the right equipment, monitor the electrolyte bath, and follow the correct process parameters. Working with a reputable supplier can help to ensure that the process is successful and that any potential problems are avoided.

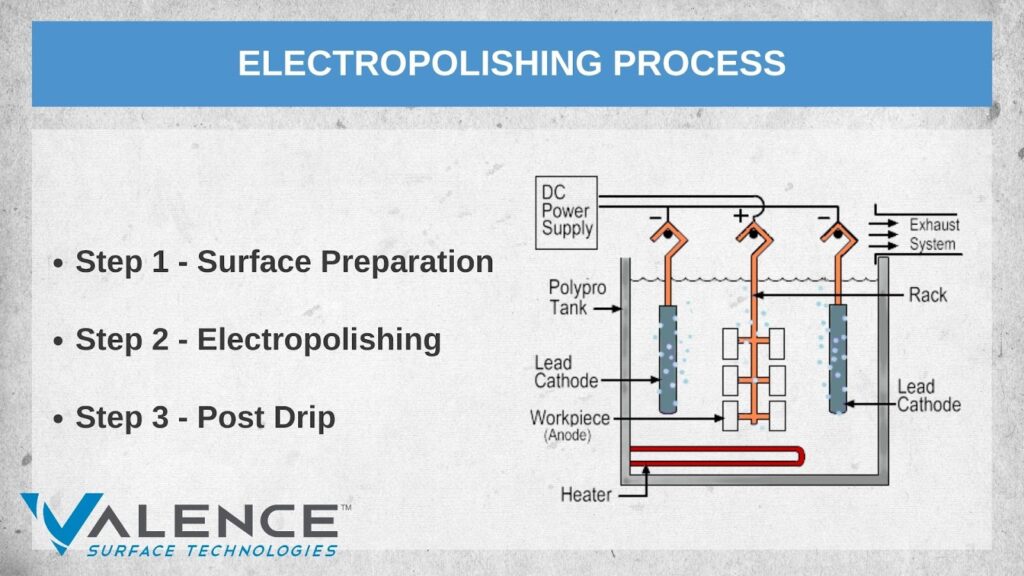

Electropolishing Process

Step 1 – Surface Preparation

The first step in the electropolishing process is surface preparation. Before beginning the electropolishing process, the metal’s surface must be meticulously cleaned. This is done to get rid of any contaminants like oils, dirt, or other substances that might be on the surface. Any scale, rust, or other oxidation that may be present on the surface must also be absent. To ensure a strong electrical connection between the metal and the electropolishing solution, the surface is next prepared. This is accomplished through sanding, grinding, or a chemical etching procedure. The electropolishing procedure can start once the surface has been properly cleaned and prepared.

Step 2 – Electropolishing

The process of polishing and sanding a metal part’s surface with an electric current is known as electropolishing. This procedure is carried out in an electrolyte solution, which is typically a blend of phosphoric and sulfuric acids. The surface layer of metal is removed as a result of the electric current drawing metal ions in the solution to the part. Up until the desired finish is attained, this process is repeated. Numerous metals, such as titanium, aluminum, and stainless steel, can be processed using this method. Typically, the electropolishing procedure is carried out between 60 and 75 °C. The type of metal being electropolished and the desired finish determine the temperature and current to be used. Normally, the current is kept low to protect the component from harm. The electropolishing process can be used to remove burrs, scale, and other surface defects, as well as to create a smooth, polished finish. The process can also be used to remove oxides from the surface of the part, which helps to increase corrosion resistance. Electropolishing can also be used to improve the surface finish of fragile parts, as well as parts with complex shapes. The electropolishing process is typically done in two stages. First, the part is submerged in the electrolyte solution and the electric current is applied. This removes the surface layer of metal and creates a smooth finish. Then, the part is rinsed with water and dried. This removes any remaining electrolyte solution and prepares the part for the next step in the process.

Step 3 – Post Drip

After the electropolishing process is complete, the parts must be rinsed with a water wash to remove any residue that may have been left behind. This is known as post-drip. After the parts are rinsed, they must be dried to prevent any further corrosion. Depending on the specific part, they may be dried in an oven, with a hot air gun, or with a vacuum chamber. Once the parts are dry, they are ready to be used in the aerospace industry.

Our Electropolishing Services

At Valence Surface Technologies, we are committed to providing the highest quality electropolishing services for aerospace applications. Our experienced team of technicians is dedicated to providing the best possible results for each project, ensuring the highest level of precision and accuracy. We use state-of-the-art equipment and the latest technology to provide our customers with the best possible service. Our electropolishing services include: • Deburring: Our deburring process removes sharp edges and burrs from metal parts, ensuring that they are safe and reliable. • Passivation: Passivation is a process that removes surface contaminants from metal parts, improving their corrosion resistance. Get a quote here. • Brightening: Our brightening process increases the brightness and luster of metal parts, making them more aesthetically pleasing. • Micro-smoothing: Our micro-smoothing process improves the surface finish of metal parts, making them smoother and more resistant to wear and tear. We strive to provide our customers with the highest quality of service and the best possible results. Our commitment to excellence and customer satisfaction has allowed us to become one of the leading providers of electropolishing services for the aerospace industry. If you have any questions about our services or would like to learn more about how we can help you, please don’t hesitate to contact us.

Final Thoughts

In the aerospace sector, electropolishing is a crucial procedure that offers many advantages. It can be used to deburr, clean, and smooth, complex parts, provides a smooth and ultra-clean finish and gets rid of oxide scale. Additionally, it reduces friction, cleans up surface flaws, and enhances the durability and corrosion resistance of the component. Despite the risks, they can be controlled with the appropriate procedures and tools. As a market leader in aerospace surface finishing, Valence Surface Technologies provides its clients with products and surface finishes of the highest caliber. Contact us today to learn more about how we can help you with your aerospace finishing needs.

FAQs

How Much Material Is Removed By Electropolishing?

The amount of material removed during electropolishing depends on the type of metal being treated, the current density, and the time of the process. Generally, the amount of material removed is between 0.0001” and 0.0005” per minute.

Which Metals Work With Electropolishing?

Electropolishing works best with stainless steel, aluminum, titanium, and other non-ferrous metals. It can also be used on some ferrous metals like steel and iron, but the results may not be as good.

Is There A Specification Or Standard That Electropolishing Is Performed To?

Yes, there are several standards for electropolishing. ASTM B912-16 is a common standard used in the aerospace industry, and it specifies requirements for electropolishing of stainless steel and titanium components.

Which One Is Better, Passivation Or Electropolishing?

It depends on the application. Passivation is a chemical process that removes free iron from the surface of metal components. It is used to improve the corrosion resistance of the metal, but it does not improve the surface finish. Electropolishing, on the other hand, does improve the surface finish, but it does not provide any additional corrosion protection. Therefore, it is best to use the process that is most appropriate for the application.