Key Takeaways:

- MIL-C-83286 coatings offer exceptional durability, chemical resistance, and weather resistance. This makes them ideal for protecting aerospace and military components from harsh environmental conditions.

- MIL-C-83286 coatings are used in a wide range of aerospace applications, including aircraft exteriors, components, and military equipment.

- Compliance with MIL-C-83286 is essential for ensuring the safety, reliability, and performance of aerospace products. Manufacturers must follow rigorous testing and quality control procedures to ensure their coatings meet the standard’s requirements.

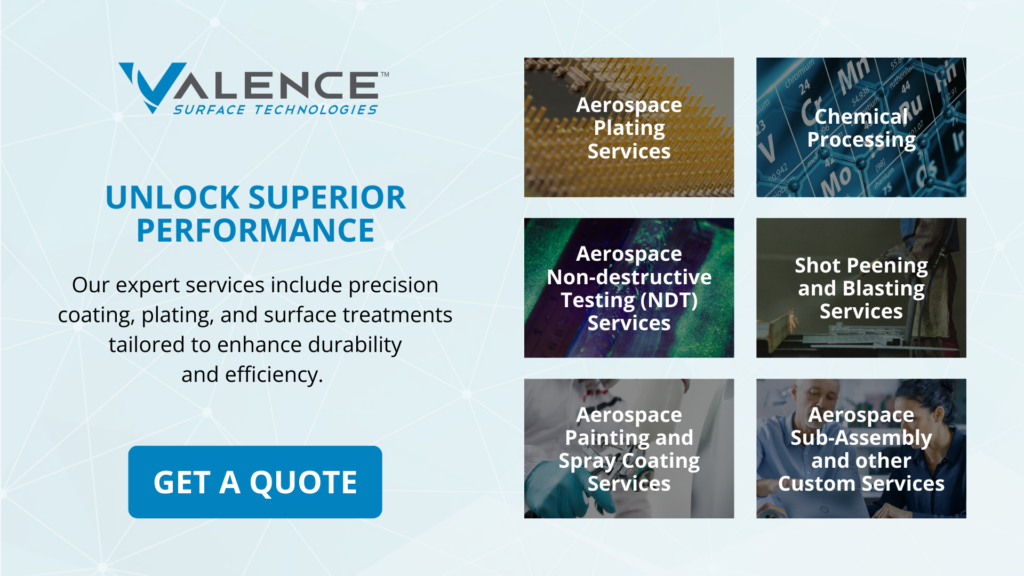

In the high-stakes world of aerospace manufacturing, adhering to strict military specifications is not just a requirement but a commitment to quality and performance. MIL-C-83286, a critical specification for polyurethane coating systems, demands precision, durability, and excellence in application. At Valence Surface Technologies, we understand these requirements and excel at meeting and surpassing them.

Contact us today to elevate your aerospace components to the pinnacle of performance and protection.

What Is MIL-C-83286?

MIL-C-83286 specifies the requirements for a high-performance coating material used extensively in the aerospace and defense industries. This aliphatic polyurethane coating offers outstanding resistance to chemicals, solvents, abrasion, and weathering. It is specifically engineered for its durability, flexibility, and capability to withstand extreme environmental conditions, making it an essential protective layer for aircraft, aerospace vehicles, and related equipment.

The specification for MIL-C-83286 includes detailed requirements for the coating’s composition, ensuring that it provides not only high-level protection but also maintains the structural integrity of the substrates it covers. This makes MIL-C-83286 coatings ideal for critical aerospace applications where performance cannot be compromised. Additionally, the specification outlines the application methods, curing times, and expected performance outcomes, ensuring that products meeting this standard deliver consistent quality and reliability.

Key Characteristics And Properties Of MIL-C-83286 Coatings

MIL-C-83286 coatings are specifically engineered to meet the rigorous demands of aerospace applications. Their unique properties make them ideal for protecting various aerospace components from harsh environmental conditions and mechanical stresses.

Key Characteristics:

- Urethane-based: The primary component of MIL-C-83286 coatings is urethane, a polymer renowned for its toughness, durability, and resistance to weathering. Urethanes are known for their flexibility, allowing them to withstand aircraft stresses in flight and landing.

- Aliphatic isocyanate: Aliphatic isocyanate is the crosslinking agent used in MIL-C-83286 coatings, contributing to the coating’s overall performance and durability. Aliphatic isocyanates are less reactive than aromatic isocyanates, making them more suitable for outdoor applications and reducing the risk of yellowing or discoloration.

- Aerospace-grade: These coatings are formulated to meet the stringent requirements of aerospace environments, including exposure to extreme temperatures, chemicals, and mechanical stresses. They must also withstand the harsh conditions encountered during flight, such as temperature fluctuations, exposure to UV radiation, and the corrosive effects of atmospheric pollutants.

Properties:

- Durability: MIL-C-83286 coatings are highly resistant to abrasion, impact, and weathering, ensuring long-lasting protection. They can withstand the constant buffeting and vibration experienced by aircraft during flight and the effects of rain, snow, and other environmental factors.

- Chemical resistance: They can withstand exposure to various chemicals and solvents, making them suitable for use in environments where corrosion is a concern. This is particularly important in aerospace applications, where components may come into contact with fuels, lubricants, and other chemicals.

- Adhesion: These coatings exhibit excellent adhesion to various substrates, including metals, composites, and plastics. This ensures that the coating remains firmly bonded to the underlying material, preventing delamination and providing a barrier against corrosion.

- Weather resistance: MIL-C-83286 coatings are designed to protect against UV radiation, moisture, and temperature extremes. They can withstand the harsh effects of sunlight, which can cause degradation and fading, as well as the challenges posed by extreme temperatures, such as freezing and thawing cycles.

- Aesthetics can be formulated in various colors and finishes to meet specific aesthetic requirements. While functionality is a primary concern in aerospace applications, appearance can also be important, especially for civilian aircraft.

The Benefits Of MIL-C-83286 Coatings In Aerospace And Military Applications

These coatings are notable for their robust characteristics, making them an ideal choice for protection and durability in some of the most challenging environments. Here’s a closer look at the benefits these coatings offer.

Enhanced Durability and Longevity

One of the primary benefits of MIL-C-83286 coatings is their enhanced durability. These coatings provide a hard yet flexible protective layer that can withstand extreme environmental conditions, including high temperatures, UV exposure, and chemical attacks.

This resilience extends the lifespan of aerospace components by protecting against corrosion, erosion, and wear, ensuring that they remain operational longer with less frequent maintenance or replacement needs.

Superior Resistance to Environmental Factors

Aerospace and military equipment must perform reliably in various environments, from the freezing temperatures of high altitudes to the blistering heat of desert operations. MIL-C-83286 coatings are formulated to offer superior resistance to a broad spectrum of environmental factors.

Their ability to resist the degrading effects of UV light, moisture, salt, and a wide range of chemicals makes them an indispensable protective measure for components exposed to harsh operational environments.

Improved Aesthetic and Functional Properties

Beyond their protective qualities, MIL-C-83286 coatings also enhance coated surfaces’ aesthetic and functional properties. These coatings come in various colors, allowing for compliance with visual identification standards and providing a smooth, hard finish that reduces friction and drag on aerospace components. This can contribute to improved aerodynamics and fuel efficiency, which are especially critical considerations in the aviation industry.

Compliance with Military Specifications

Compliance with stringent specifications is non-negotiable for defense contractors and military suppliers. MIL-C-83286 coatings meet these rigorous standards, ensuring that components coated with this polyurethane technology comply with the highest military requirements for durability, performance, and environmental resilience. This compliance is not just about meeting current needs but also about future-proofing components against evolving challenges.

Applications Of MIL-C-83286

MIL-C-83286 coatings are widely used in various aerospace applications due to their exceptional properties and ability to withstand the harsh conditions encountered in flight. Here are some of the primary applications:

Aircraft Exteriors:

- Fuselage protects the aircraft’s main body from environmental factors such as rain, snow, UV radiation, and corrosion.

- Wings: Provides a durable and weather-resistant coating for the wings, ensuring optimal performance and structural integrity.

- Empennage: Protects the aircraft’s tail section, including the vertical and horizontal stabilizers, from environmental damage.

- Nose cone: Protects the sensitive radar and other equipment housed in the nose cone from impact and weathering.

Aerospace Components and Structures:

- Landing gear: Provides a durable and corrosion-resistant coating for the landing gear, ensuring safe and reliable operation.

- Engine components: Protects engine parts such as the compressor, turbine, and exhaust system from heat, corrosion, and erosion.

- Interior panels: Provides a durable and aesthetically pleasing finish for interior panels and components.

- Cargo doors: Protects cargo doors from corrosion, impact, and weathering, ensuring safe and efficient loading and unloading.

Military Equipment:

- Missiles: Provides a durable and weather-resistant coating for missile bodies and components, ensuring optimal performance and storage life.

- Drones: Protects drone components from environmental factors and ensures reliable operation.

- Satellites: This material provides a durable and heat-resistant coating for satellite components, protecting them from the harsh conditions of space.

The Testing And Quality Control Process For MIL-C-83286 Coatings

A rigorous testing and quality control process is implemented to ensure that coatings meet the stringent requirements of MIL-C-83286. This process involves a series of tests to evaluate the coating’s physical, chemical, and mechanical properties.

Common Tests for MIL-C-83286 Coatings:

- Adhesion: This test measures the coating’s ability to adhere to the underlying substrate. It may involve methods such as cross-hatch adhesion testing or peel adhesion testing.

- Hardness: This test determines the coating’s resistance to indentation or scratching. Common hardness tests include pencil hardness, barcol hardness, and Shore hardness.

- Flexibility: This test evaluates the coating’s ability to withstand bending or flexing without cracking. It may involve methods such as a mandrel bend or conical mandrel test.

- Impact resistance: This test measures the coating’s resistance to impact from a falling weight. It is typically conducted using a falling dart impact tester.

- Chemical resistance: This test evaluates the coating’s resistance to various chemicals, such as solvents, fuels, and cleaning agents. It may involve immersion testing or exposure to specific chemicals.

- Weather resistance: This test assesses the coating’s ability to withstand exposure to outdoor conditions, including UV radiation, moisture, and temperature extremes. It may involve accelerated weathering testing or exposure to natural weathering conditions.

- Film thickness: This test measures the thickness of the applied coating. It may involve magnetic film thickness gauges or destructive cross-section analysis.

- Gloss: This test measures the coating’s level of shine or reflectivity. It is typically conducted using a gloss meter.

- Color: This test evaluates the coating’s color and consistency. It may involve visual inspection or color measurement using a spectrophotometer.

Quality Control Procedures:

- Incoming inspection: Inspection of raw materials and components to ensure they meet the specified requirements.

- Process control: Monitoring and controlling the coating application process to ensure consistency and quality.

- Final inspection: Inspection of the finished product to verify compliance with MIL-C-83286 standards.

- Statistical process control (SPC): Use of statistical methods to monitor and control the coating process, identify trends, and prevent defects.

By following rigorous testing and quality control, manufacturers can ensure that MIL-C-83286 coatings meet the high standards for aerospace applications. This helps to maintain the safety, reliability, and performance of aircraft and other aerospace equipment.

MIL-C-83286 Vs. Other Coating Standards: A Comparison

MIL-C-83286 is a specific military specification for urethane-based coatings, but it is not the only standard available for coatings in aerospace applications. Other standards, such as MIL-C-23228 and ASTM, also provide coating materials guidelines.

Comparison with Other Standards:

MIL-C-23228:

- Focus: Primarily focuses on epoxy-based coatings, while MIL-C-83286 focuses on urethane.

- Applications: Both standards are used in aerospace applications, but MIL-C-23228 may be more suitable for certain components or environments.

- Requirements: The specific requirements and testing procedures may differ between the two standards, reflecting the different properties and characteristics of epoxy and urethane coatings.

ASTM Standards:

- Scope: ASTM (American Society for Testing and Materials) standards cover many coating materials, including epoxies, urethanes, acrylics, and others.

- Applications: ASTM standards are used in various industries, including aerospace, automotive, and construction.

- Requirements: ASTM standards provide general guidelines for coating properties and testing methods but may not be as specific as military specifications like MIL-C-83286.

Key Differences:

- Chemical composition: MIL-C-83286 specifies urethane-based coatings, while other standards may cover different types of coatings.

- Specific requirements: Military specifications like MIL-C-83286 often have more stringent requirements and testing procedures to ensure the suitability of coatings for aerospace applications.

- Applications: While both military and ASTM standards are used in aerospace applications, military specifications may be more commonly used for critical components or sensitive equipment.

Choosing the Right Standard:

The choice of coating standard depends on several factors, including:

- Application: The application’s specific requirements will determine the most suitable coating type and performance characteristics.

- Regulatory compliance: Certain industries or applications may require compliance with specific standards or regulations.

- Cost: The cost of the coating material and the associated testing and quality control procedures may also be a factor.

MIL-C-83286 Compliance With Military And Aerospace Standards

Compliance with this standard is crucial for ensuring the safety, reliability, and performance of aerospace components.

Importance of Compliance:

- Safety: MIL-C-83286 coatings are designed to protect aerospace components from corrosion, degradation, and other environmental factors. Compliance with this standard helps to prevent failures and ensure the safety of aircraft and other equipment.

- Reliability: MIL-C-83286 coatings are known for their durability and resistance to harsh conditions. Compliance with this standard helps to ensure the long-term reliability and performance of aerospace components.

- Performance: MIL-C-83286 coatings are specifically formulated to meet the demanding requirements of aerospace applications. Compliance with this standard helps to maintain the performance and functionality of aerospace equipment.

Key Requirements for Compliance:

- Physical properties: The coating must meet specific requirements for hardness, flexibility, impact resistance, and adhesion.

- Chemical resistance: The coating must be resistant to various chemicals, including fuels, lubricants, and cleaning agents.

- Weather resistance: The coating must be able to withstand exposure to UV radiation, moisture, and temperature extremes.

- Testing and quality control: Manufacturers must follow a rigorous testing and quality control process to ensure that their coatings meet the requirements of MIL-C-83286.

Benefits of Compliance:

- Enhanced safety: Compliance with MIL-C-83286 helps to reduce the risk of failures and accidents.

- Improved reliability: Compliant coatings provide long-lasting protection and maintain the reliability of aerospace components.

- Enhanced performance: Compliant coatings help to ensure that aerospace components perform as intended.

- Regulatory compliance: Compliance with MIL-C-83286 can help manufacturers meet regulatory requirements and avoid penalties.

Ensuring Compliance:

Manufacturers can ensure compliance with MIL-C-83286 by:

- Selecting qualified suppliers: Choose suppliers who have a proven track record of producing coatings that meet the requirements of MIL-C-83286.

- Implementing quality control procedures: Establish and follow rigorous quality control procedures to monitor the coating application process and ensure product quality.

- Conducting regular testing: Conduct regular testing of coatings to verify compliance with MIL-C-83286 requirements.

- Maintaining documentation: Keep detailed records of all testing and quality control activities.

Choosing The Right MIL-C-83286 Coating For Your Needs

Here are some key considerations to make when choosing the right MIL-C-83286 coating:

- Environmental Resistance: Consider the environmental conditions your coated components will face. MIL-C-83286 coatings are engineered to resist degradation from ultraviolet (UV) light, salt spray, and various chemicals. If your components are expected to endure harsh outdoor environments or constant exposure to corrosive substances, selecting a formulation with enhanced resistance features is crucial.

- Application Process: The application method can influence your choice of MIL-C-83286 coating. Some formulations are more suited for spray application, while others may be optimized for brush or roller applications. Selecting a coating compatible with your existing application processes is essential, or you may need to adjust your processes to accommodate the optimal coating choice.

- Color and Finish Requirements: MIL-C-83286 coatings are available in various colors and gloss levels. Whether you need a specific color match for aesthetic purposes or a low-gloss finish to minimize visual detection, there’s a MIL-C-83286 formulation to meet your needs. Ensure to specify your color and finish requirements when selecting a coating.

- Operational Temperatures: Another crucial factor is the operating temperature range of the coated surface. MIL-C-83286 coatings are designed to perform under various temperature extremes, but some formulations offer superior performance at either high or low temperatures. Understanding the thermal stresses your component will encounter can guide you to the most appropriate coating choice.

- Compliance and Specifications: Ensure the MIL-C-83286 coating you choose meets your specific application’s regulatory and compliance requirements. This includes adherence to specifications for thickness, hardness, and other physical properties. Compliance with these specifications is critical for the performance and longevity of the coating.

Final Thoughts

MIL-C-83286 coatings are indispensable for aerospace and military applications, offering unparalleled protection, durability, and resistance to harsh environmental conditions. This aliphatic polyurethane coating provides an effective shield against corrosion, chemical exposure, and weathering from aircraft exteriors to sensitive military equipment.

By adhering to MIL-C-83286 standards, manufacturers ensure compliance with stringent military specifications, safeguarding the performance and longevity of critical components. Selecting the right MIL-C-83286 coating tailored to specific environmental needs is essential for maintaining operational efficiency and reliability in demanding applications.

Ready to Enhance Your Aerospace Equipment? Partner with Valence Surface Technologies for industry-standard surface finishing. Our industry-leading solutions ensure your components meet the highest performance standards. Contact us today to learn how we can help safeguard your assets!

Additional Read:

Frequently Asked Questions

What surfaces can be coated with Mil-C-83286?

Mil-C-83286 coatings are versatile and can be applied to various surfaces, including metals, alloys, and composite materials commonly used in the aerospace industry. These coatings are particularly beneficial for surfaces exposed to harsh environmental conditions, requiring exceptional protection against wear, corrosion, and high temperatures.

How long does Mil-C-83286 coating last?

The lifespan of Mil-C-83286 coatings can vary based on several factors, including the application environment, the quality of surface preparation, and how well the coating was applied. Generally, when applied correctly and maintained properly, Mil-C-83286 coatings can provide superior protection for extended periods, often exceeding 10 years, under normal conditions.

Does Mil-C-83286 require a primer?

Yes, Mil-C-83286 coatings typically require the application of a suitable primer to ensure maximum adhesion and performance. The specific type of primer recommended can depend on the substrate material and the intended service environment of the coated part. Using the appropriate primer is crucial for achieving the full protective benefits of Mil-C-83286 coatings.

Can Mil-C-83286 be applied over existing paint?

Applying Mil-C-83286 over existing paint is not generally recommended without thorough surface preparation. The existing paint must be completely removed and the surface properly prepared to ensure adhesion and the performance integrity of the Mil-C-83286 coating. Proper surface preparation may include cleaning, degreasing, sanding, or abrasive blasting.

What are the safety precautions when using Mil-C-83286?

The application of Mil-C-83286 coatings requires strict adherence to safety precautions to protect against potential hazards, including toxic vapors and flammable materials. Appropriate personal protective equipment (PPE), such as respirators, gloves, and protective eyewear, is essential. Adequate ventilation and compliance with local environmental and occupational safety regulations are also crucial.

What colors are available in Mil-C-83286 coatings?

Mil-C-83286 coatings are available in a range of colors designed to meet the specific requirements of military and aerospace applications. The standard color options include but are not limited to, various shades of green, gray, black, and white. Custom color formulations can also be created to meet a project’s specific aesthetic or functional requirements.