Gold plating serves as a renowned metal finishing strategy that incorporates a delicate gold layer onto a metal object’s surface. This gold veneer delivers an array of advantages such as augmented corrosion resistance, superior electrical conductivity, enhanced heat resistance, increased wear resistance, and an overall durability boost.

In this article, we’ll delve into the intricacies of the gold plating process, discussing its advantages in-depth, along with its various types – hard, soft, duplex, vacuum, and chemical plated & immersion gold plating. We’ll also detail how each type is specifically applied to different scenarios, enhancing the lifespan and performance of aerospace components.

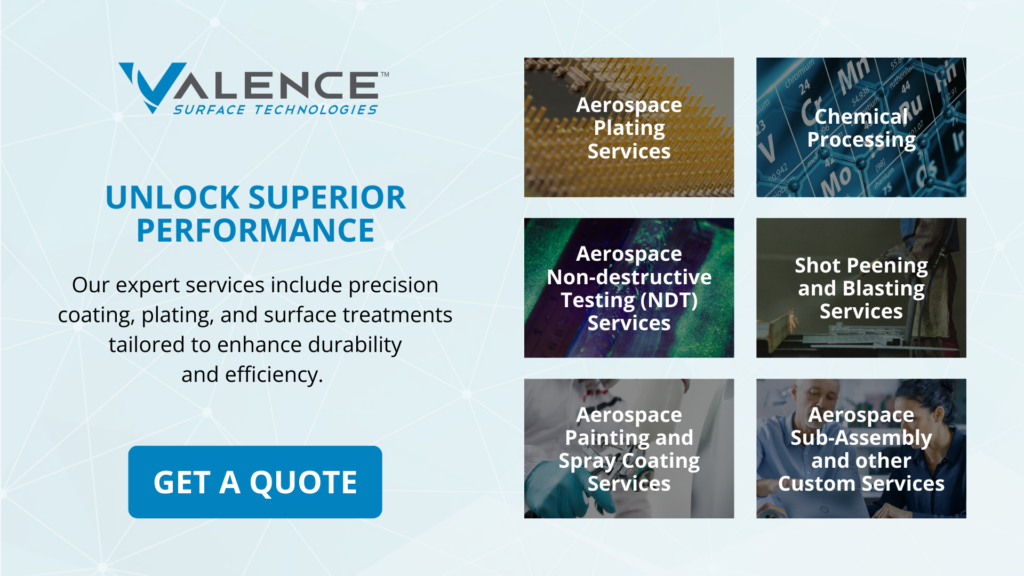

If you’re seeking expertise in gold plating services for your aerospace application, look no further than Valence. We offer a wealth of knowledge and proficiency that guarantees a quality result tailored to your specific needs. Contact us today and let our experts provide the superior service you seek.

What Is Gold Plating?

Gold plating is a technique where a thin layer of gold, usually between 0.25 to 2.5 microns thick, is applied to the surface of a metal or other material. This is accomplished through electroplating, a chemical process that enhances the material’s appearance and durability while also providing corrosion resistance. Gold plating finds extensive use in diverse sectors such as aviation, defense, medical/life sciences, as well as space and communication systems due to its advantageous properties.

How Does It Work?

Gold plating represents a metal finishing procedure where a thin layer of gold is layered onto another metal’s surface. This is accomplished using electroplating, a method that employs an electrical current to facilitate the deposition of a slender layer of gold onto the metal’s surface.

Different Types Of Gold Plating

There are various types of gold plating, each with its own unique properties and benefits. Here are different types:

Hard Gold Plated

Hard gold plating, also known as hard electrolytic gold, signifies a variant of the gold plating process where a substantial layer of gold is deposited onto a substrate. This method is extensively utilized in electronic and electrical applications due to its inherent durability, resistance to wear, and excellent conductivity.

Soft Gold Plate

Soft gold plating, also known as soft electrolytic gold, is a gold plating process in which a comparatively thin layer of gold is deposited onto a substrate. In contrast to hard gold plating, the emphasis in soft gold plating is on the purity and suppleness of the gold layer rather than its hardness.

This method is typically employed in applications necessitating superior electrical conductivity and minimal contact resistance, including semiconductor devices, connectors, and specific high-frequency applications.3

Duplex Gold Plated

Duplex gold plating is a specialized gold plating procedure that applies both hard and soft gold layers to a substrate. This method strategically amalgamates the advantages of both hard and soft gold plating, resulting in a bespoke balance of hardness, wear resistance, and electrical conductivity, aligning with specific application requirements.

Vacuum Gold Plated

Vacuum gold plating is a unique metal finishing process, employed to apply a thin gold coating over various surfaces. The procedure necessitates a vacuum chamber, creating a vacuum environment conducive to the application of gold ions onto the substrate’s surface.

Drawn to the substrate, the gold ions constitute a thin layer of gold coating, which is subsequently sealed and safeguarded by a transparent protective coating. Remarkably efficient, this method generates a uniform and consistent layer of gold plating.

Chemical Plated & Immersion Gold Plated

Chemical plated & Immersion gold plating is a specific gold plating process wherein the metal surface is submerged in a chemical solution enriched with gold ions. An electric current activates this solution, leading the gold ions to adhere to the metal surface, creating a thin yet robust layer of gold.

This technique is particularly beneficial for aerospace applications, owing to its exceptional corrosion resistance and superior electrical conductivity when compared to other gold plating types. Further, the gold-plated layer offers increased wear resistance, rendering it ideal for components exposed to heavy use or significant wear and tear.

Discover the unparalleled advantages of gold plating services with Valence. Don’t just take our word for it – reach out to us and let’s discuss how we can best serve your needs.

Check out: A Bright Future: Exploring The Benefits Of Gold Plating In Aerospace

Benefits Of Gold Plating In Aerospace

Gold plating is an increasingly popular choice for aerospace metal finishing due to its superior performance characteristics. It offers numerous benefits to aerospace applications, including

Increased Corrosion Resistance

Gold plating significantly enhances corrosion resistance compared to other metal finishing methods. This is primarily due to the gold layer serving as a protective barrier, preventing the underlying metal from exposure to corrosive substances and oxidation that could lead to corrosion. The high resistance of gold plating to a broad spectrum of chemicals, including acids and alkalis, further boosts its anti-corrosion attributes.

Improved Electrical Conductivity

The practical method of gold plating increases the electrical conductivity of a metal surface. As gold is an intrinsically highly conductive metal, its application to a surface forms a uniform electrical pathway, facilitating a more efficient current flow. Furthermore, gold plating can reduce a surface’s electrical resistance, safeguarding sensitive electronic components from potential damage caused by static electricity.

Superior Heat Resistance

One of the key advantages of gold plating in aerospace applications is its superior heat resistance. Gold plating exhibits a low coefficient of thermal expansion, signifying minimal expansion or contraction with temperature changes. This characteristic is important for components needing stability and protection amidst extreme temperature variations.

Enhanced Wear Resistance

Gold plating bestows enhanced wear resistance, rendering it a preferred choice for aerospace applications. The gold layer serves as a barrier against the environment, safeguarding the underlying metal from oxidation and corrosion.

Moreover, gold plating functions as a lubricant, diminishing friction, and consequent wear and tear, making it optimal for parts that undergo substantial movement or frequent contact with other surfaces.

Durability Enhancement

In aerospace applications, the durability and longevity offered by gold plating are paramount benefits. Gold’s innate resistance to corrosion guarantees component protection against the severe conditions typical in the aerospace environment. This protective layer notably extends the life of critical parts, thereby diminishing the frequency of replacements and minimizing maintenance-induced downtime.

Step-By-Step Gold Plating Process

Here’s a step-by-step guide to the gold plating process:

Step 1: Surface Preparation

It entails thorough cleaning of the metal to ensure proper gold adhesion. It often employs methods such as pickling, sandblasting, or degreasing to remove dirt, grease, or oxidation and eliminate surface defects.

Step 2: Cleaning

The cleaning phase of gold plating uses various methods, like ultrasonic cleaning, vapor degreasing, and chemical cleaning, to eradicate contaminants from the component. Choosing a suitable cleaning method is essential as it impacts the effectiveness of the plating process.

Step 3: Rinse

Next, the components are rinsed using deionized water to remove impurities and ready for the subsequent plating stages. Agitation of the parts in water helps in dislodging any residual contaminants.

Step 4: Strike

In this step, a strike layer (a thin plating layer) of high-quality nickel is applied to the surface of the clean base metal. This helps improve the adhesion of the gold to the surface and also helps prevent tarnish that can occur down the road.

Step 5: Rinse Again

Post base coat application, the product undergoes another rinse to eliminate any residues. A high-pressure hot water rinse is optimal, followed by drying with compressed air or a cloth.

Step 6: Base Coat

A critical step, the base coat provides a foundation for the gold plating layer, ensuring uniform coverage and a strong bond. Usually, an electroless nickel plating is employed, acting as a protective barrier and enhancing the adhesion and durability of the gold plating.

Step 7: Final Coating

The final coating applies the gold alloy by immersing the part in a gold alloy tank and electroplating it using a DC power supply. The gold layer’s thickness can be adjusted, followed by drying and polishing for a smooth finish.

Step 8: Final Rinse

The gold plating process concludes with a final rinse to remove excess solution or plating material, ensuring the part is free of residues. Drying with compressed air or a heat gun follows to eliminate residual moisture and prevent oxidation.

Dive Deeper Into Gold Plating With Valence

Valence is a leading provider of gold plating services, specializing in aerospace applications. Our team of experienced metal finishing professionals delivers exceptional gold plating solutions using state-of-the-art equipment. We offer a wide range of options tailored to your specific requirements, including hard gold plating, soft gold plating, duplex gold plating, vacuum gold plating, chemical plating, and immersion gold plating.

Our gold plating services provide numerous benefits for aerospace applications. These include improved corrosion resistance, optimized electrical conductivity, superior heat resistance, enhanced wear resistance, and overall durability enhancement.

We follow a systematic process that begins with surface preparation, followed by cleaning, rinsing, and striking. Then, another round of rinsing is performed before applying a base coat and final coating. The process concludes with a final rinse, ensuring the highest quality results.

If you need superior gold plating services for your aerospace application, trust the experts at Valence. Contact us today to learn more about our gold plating services and discover how we can help you achieve the best results.

Final Thoughts

Gold plating stands as an incredibly flexible and reliable metal finishing technique, extensively employed in aerospace applications for many years. This technique serves as a dependable method to amplify the conductivity, resilience, and visual appeal of aerospace components.

The process unfolds over several stages, encompassing surface preparation, cleaning, rinsing, striking, application of a base coat, and culminating in a final coat. An understanding of the diverse gold plating variants, such as hard, soft, duplex, vacuum, and chemical plated & immersion gold plating is essential.

Are you ready to amplify the durability and aesthetics of your aerospace components? Request a quote today or kindly contact us to learn more about our gold plating services and how we can help you achieve the perfect finish for your aerospace components.

Discover more by delving into our extensive collection of blogs:

- Top Surface Finishing Applications In Aerospace

- A Bright Future: Exploring The Benefits Of Gold Plating In Aerospace

- Anodizing Aluminum For Aerospace Applications: A Comprehensive Guide

FAQs

Are gold-plated products expensive?

Gold-plated products can vary in cost depending on the thickness of the plating, the type of gold used, and the complexity of the product. Generally, gold-plated products will be more expensive than silver-plated products due to the higher cost of gold.

What are the key differences between gold-plated and silver-plated?

The primary difference between gold-plated and silver-plated products is the metal used. Gold-plated products are made with a thin layer of gold, while silver-plated products are made with a thin layer of silver. Additionally, gold-plated products tend to be more expensive than silver-plated products due to the higher cost of gold.

How long does a gold-plated product last?

The longevity of a gold-plated product depends on the thickness of the plating and the environment in which it is used. Generally, gold-plated products can last for years with proper care and maintenance.

How thick are gold-plated products?

The thickness of gold-plated products varies depending on the product and the desired finish. Generally, gold-plated products will have a plating thickness between 0.5 and 2.5 microns.

Do gold-plated products tarnish?

Gold-plated products can tarnish over time, although this process can be slowed with proper care and maintenance. Additionally, some gold-plated products are treated with a layer of lacquer to protect the plating and reduce the rate of tarnishing.

SOURCES:

- Gold Plating – an overview | ScienceDirect Topics. (n.d.). Www.sciencedirect.com. https://www.sciencedirect.com/topics/chemical-engineering/gold-plating

- Plating on Hard Gold vs. Plating on Soft Gold | Blog | SPC. (2019, October 6). Sharretts Plating Company. https://www.sharrettsplating.com/blog/hard-vs-soft/#:~:text=In%20hard%20gold%20plating%2C%20the