Because of their desirable qualities, metals like aluminum, magnesium, titanium, etc., have been used in a variety of industries, including the automotive, aerospace, electronics, etc. However, these applications necessitate the use of these metals under challenging operating environments. Certain circumstances, which cause these metals to lose some of their qualities, include high humidity, high temperatures, the presence of acids and salts in a service environment, etc. This causes certain metals to fail in use, which raises the expense of maintenance or component replacements. When used in these circumstances, techniques have been developed to preserve these metals. One method for protecting these metals from hostile working environments is anodizing. It contributes to making these metals more resilient, which lowers the price of component replacement and maintenance. In this article, we will discuss all you need to know about anodizing, its purposes, benefits, types of the anodizing process, and its application in the aerospace industry.

What Is Anodizing?

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Although other nonferrous metals, such as magnesium and titanium, can also be anodized, aluminum is best suited for the process. The anodic oxide structure, made completely of aluminum oxide, comes from the aluminum substrate. This aluminum oxide is totally integrated with the underlying metal substrate rather than being applied to the surface like paint or plating, making it resistant to chipping and peeling. In addition, its well-organized porous structure enables further procedures like coloring and sealing. Aluminum is anodized by dipping it into an acid electrolyte bath and then running an electric current through it. The anodizing tank has a cathode mounted inside of it; aluminum serves as the anode, causing oxygen ions to be released from the electrolyte and combined with aluminum atoms on the surface of the component being anodized. Therefore, anodizing is the enhancement of a naturally occurring phenomenon through carefully controlled oxidation.

What Is Anodizing Used For?

Anodizing is a low-cost, high-quality finishing method. As a result, it is widely used in a number of applications across numerous sectors. Its applications are so varied that chances are you utilize an anodized metal component every day.

- Aerospace.

- Automotive.

- Architecture.

- Consumer goods.

- Homeware sectors.

How Does Anodizing Work?

The name itself provides a clear explanation of how anodizing functions. To anodize a part, you connect it to a positive terminal of an electrical circuit, also called an anode. The component is then placed in an electrolyte bath solution that is acidic. Chemical elements in this solution, including sodium phosphate, flood the bath with positive and negative ions. You connect the negative end of the circuit, or cathode, to a metal electrode in the bath once the component has been immersed and fastened to a hanger so it won’t move. The aluminum component draws negative O2 ions (anions) from the solution, and the negative electrode draws positive ions (cations) from the component when voltage is applied to the circuit. When positive aluminum ions leave the part’s surface, it becomes porous, reacting with the negative O2 ions to grow a layer of aluminum oxide. Let’s break the process down into these simple steps:

- Turn the part into an anode with a positive charge

- Turn the metal plates into the cathode with a negative charge

- Submerge both in the acidic bath

- Apply voltage

- Subtract aluminum ions from the part, creating pores

- Attract oxygen ions to the part’s surface

- The reaction forms a hard, corrosion-resistant aluminum oxide layer

How Anodizing Aluminum Works

The process of anodizing aluminum works with the following steps:

Pre-Treatment

A part must first have its surface treated mechanically and chemically before being anodized. Polish or bead blast the surface first to give your part the desired look. Bead blasting will give your part a naturally matte finish, whereas brushing will give it a brushed appearance. The chemicals you use prior to anodizing will have an impact on how glossy your product is. For example, etching will give your item a beautiful satin surface. For a glossy finish, pick brilliant dipping or chemical polishing.

Rinsing

By rinsing the item in deionized water and other solvents, impurities from the item, such as machining waste like lubricants and coolant, can be removed. Immerse the cleaned parts in a sodium hydroxide (NaOH) and nitric acid solution to remove the metal’s surface coating (HNO3). If the item has already undergone mechanical treatment, this procedure is not always necessary. You can conceal those spots to prevent the formation of an anodizing surface there.

Etching (Chemical Milling)

Alkaline etching frequently involves the use of sodium hydroxide solution. The result is a light-gray satin shine on the metal’s surface (through a diffuse reflection of the incident light). The overwhelming majority of jobs use this pre-treatment technique. The rate at which an object etches depends on several factors, including the temperature, the amount of sodium hydroxide solution present, and the quantity of aluminum ions released into the solution. When aluminum ions are present in high concentrations, the solution loses its effectiveness. There might be additional ions, some of which might be alloy components, interfering with the process and leaving imperfections on the surface of the work. The problem of ion contamination is resolved by utilizing etching solutions that prevent the effect of the released Al3+ and other metal ions. The components of these solutions are secret to the companies that make them, however, they frequently contain sequestering agents that contain complex metal ions. Although these solutions don’t have an unlimited capacity to do this, the etching batch is kept in an effective state because the etched work “carries over” the solution and is occasionally replaced by a new etch solution. The etching solution also contains foaming agents, which work to lessen the strong fumes and mists that emerge from the intense reactions. It’s vital to remember that the final product’s appearance is decided at this point. No matter how well the piece is anodized or tinted, improperly etched work will show scratches or flaws.

Acid Desmutting

The aluminum develops a “smut” coating as a result of etching. The gray-to-black smut is the insoluble alloy residue left over after the aluminum has been etched away. A nitric acid solution is most frequently used to remove this smut, leaving a prepared surface ready for anodizing.

Anodizing

Place the component(s) in the anodization bath while the electrical circuit still powers it. The solution’s composition, temperature, current density, voltage, and time are just a few examples of the parameters that can change depending on the desired attributes mentioned above.

Coloring

You can control the component’s color during anodizing. The visible spectrum’s nanometer-sized wavelengths can reflect light in a variety of ways, depending on the thickness of the oxide coating. Different parameters are used to produce diverse hues. To give your part a bronze or black shine, submerge it in a solution of metallic salts. These interact with the surface to fill the pores with a bronze- or black-colored chemical compound. Electrolytic coloring is the name given to it. Dip coloring, which fills the pores with a dye solution, might be used if you desire a different color. Place your component after dipping it in the dye in warm DI water to stop any additional reactions. Dip coloring is the least resilient of the coloring techniques described here since the color may deteriorate over time if exposed to UV light.

Sealing

After anodizing, the surface of the component must be sealed to prevent further corrosion and improve performance. If the pores are not sealed, anodized items could have a sticky feel to them. Additionally, open pores can become clogged with grime, toxins, and stains. There are three common processes for sealing pores:

Hot DI Sealing

This method involves immersing the component in deionized water that has been nearly brought to a boil. When the component combines with the water, a substance called böehmite, or hydrated aluminum oxide is produced. Boehmite fills the pores and occupies more space than aluminum oxide. The process of standardizing this is simple. However, it has a high energy consumption and might cause dye bleed and color leakage on dyed goods.

Mid Temperature Sealing

This technique, which uses metal salts in a solution like salts of nickel, magnesium, or cobalt to react with the surface and fill the pores, requires less energy than heat sealing. This technique lessens sealing smut or surface mineral deposits and is preferable for colored components. However, it’s more challenging to control and challenging to repeat with the same accuracy.

Cold or Room Temperature Sealing

Cold sealing chemistries frequently use nickel-fluoride formulations that interact with the porous aluminum oxide layer to generate a sealed fluoro-aluminate layer that is then deposited on the surface. The surface is etched during this process to improve performance and adherence. Additionally, it complies with a few automotive and military standards. It can be slow, though, and may need a hot water bath to hasten the curing process, making it more difficult to manage.

What Materials Can Be Anodized?

The materials that can be anodized are as follows:

Aluminum

The most common materials to be anodized are aluminum and aluminum alloys. Because of its high strength-to-weight ratio and relative availability, aluminum is utilized extensively in industrial operations. Aluminum’s overall performance is enhanced, and its useful life is increased by anodizing. There are numerous distinct aluminum anodizing procedures.

Magnesium

Magnesium is typically anodized for use as a paint primer, and for this application, thin coatings (as little as 5 m) are adequate. Magnesium materials can have their corrosion resistance improved by having anodic coatings that are thicker (25 m or more). For best results, these coatings need to be sealed with sodium silicate, wax, or oil. The following specifications are applicable for magnesium anodizing: AMS 2466, AMS 2478, AMS 2479, and ASTM B893.

Titanium

The jaw, hip, and knee implants are frequently made of anodized titanium. In addition, anodized titanium is popular for art, costume jewelry, body piercing jewelry, and wedding bands because the anodizing technique may produce various hues without using dyes. The oxide layer’s thickness, ranging from 30 nanometers to several micrometers, affects color. The anodizing voltage, in turn, controls thickness. AMS 2487 and 2488 are applicable standards for anodized titanium.

Niobium

Similar chemicals and procedures to anodizing titanium can be used on niobium. By altering the coating thickness, which is also reliant on anodizing voltage, a variety of colors can be produced. Costume and body jewelry, commemorative coins, and other highly attractive objects are frequently made of anodized niobium.

Tantalum

needs to be anodized using a method similar to that of titanium and niobium. By adjusting the film thickness, a variety of appealing colors can be created. Depending on the chemical solution employed and the process temperature, the voltage needed to anodize tantalum typically ranges from 18 to 23 Angstroms per volt. The most popular type of tantalum used to make capacitors is anodized tantalum.

Zinc

The process of anodizing zinc can be challenging. When used with voltages as high as 200V DC, a mixture of ammonium phosphate, chromate, and fluoride can create anodized coatings up to 80 m thick on zinc alloys, enhancing their hardness and corrosion resistance. Zinc-plated steel components can be anodized utilizing chemical baths comprising sodium silicate, sodium hydroxide, borax, sodium nitrate, and nickel sulfate at lower voltages (20-30V DC). MIL-A-81801 is one of the applicable specifications for anodized zinc.

Benefits of Anodizing Aluminium

The benefits of anodizing aluminum include:

Durability

The majority of anodized items have extraordinarily long lifespans and provide significant financial benefits due to maintenance and operational cost savings. For complete bonding and unrivaled adhesion, anodizing is a reactive finish that is merged with the underlying metal.

Color Retention

The majority of anodized items have extraordinarily long lifespans and provide significant financial benefits due to maintenance and operational cost savings. For complete bonding and unrivaled adhesion, anodizing is a reactive finish that is merged with the underlying metal.

Simple Maintenance

There are hardly any scars or wear from fabrication, handling, installation, routine surface dirt cleaning, or use. An anodized surface may typically be cleaned with mild soap and water or rinsed to bring back its original appearance. For harder deposits, you can use mild abrasive cleansers.

Aesthetics

Anodizing decreases or completely removes color inconsistencies while providing a vast array of gloss and color options. In addition, Anodizing, unlike other finishes, enables aluminum to keep its metallic appearance.

Cost

Greater long-term value is produced by a lower initial finishing cost combined with lower maintenance expenditures.

Safety and Health

Anodizing is a harmless technique that has no negative effects on health. Anodized finishes are non-toxic, stable chemically, won’t break down, and can withstand heat up to the melting point of aluminum (1,221 degrees F.) The anodizing process is non-hazardous and has no toxic or dangerous byproducts because it strengthens a naturally existing oxide reaction.

Disadvantages Of Anodizing Aluminium

- Only certain grades of aluminum are suitable for this technique,

- Stainless steel, which is resistant to mortar, salt, chlorine, and marine environments, cannot be utilized with this product.

- This process draws from the base metal, allowing for color changes.

- In low-grade metals, no match is achievable across batches, making consistency between batches more difficult to recreate than in high-grade metals where a 95% match is possible.

- The priciest option for modest quantities (requires a higher-grade alloy in addition to the already high set-up costs).

Types Of Anodizing Process And Uses

The type of anodizing processes and uses are as follows:

Type I

The main purpose of chromic acid anodizing is to protect important joints and structures. Considering the coating’s thickness, which is normally between 0.08 and 0.2 mils, the corrosion resistance is very good. The formed oxide film is softer and less porous than those made using the other procedures, and it is produced without suffering significant material fatigue loss. The film is easily degraded, and the color is a light opaque gray. When this film is sealed with a dichromate seal, it develops a greenish hue. The technique is voltage controlled, commencing with a ramping increase up to 40 volts, depending on the kind offered. Type I and Type IB are the two varieties that are specified by the military specification MIL-PRF-8625F. While Type IB works at a voltage of 20 to 22 volts, Type I generates typical coatings at a voltage of around 40 volts.

When Is It Used?

Chromic acid anodizing is a metal coating process used when the application calls for a thin coating and a high level of corrosion resistance. An aluminum component is submerged in a chromic acid bath during a chemical conversion procedure to produce a Type I coating.

Pros

- Corrosion protection

- Non-conductive / electrical insulation

- Improved dielectric strength

- Lesser absorption of pigmentation

- Appropriate for parts with tight tolerances

- Accepts a higher degree of flexion

Type II

The most used anodizing technique is type 2 anodizing, often known as sulfuric acid anodize. A protective coating of aluminum oxide is created by altering the surface of an aluminum substrate material. It is best suited for situations where hardness and abrasion resistance are necessary. Additionally, sulfuric acid anodize can be used as a foundation for paint systems or to increase surface corrosion and protection under demanding operating circumstances. In particular, the fabrication of colorful surface finishes on aluminum, and related alloys take advantage of the porous character of sulfuric acid coatings before sealing.

When Is It Used?

Sulfuric anodizing is widely used across all industries for general and commercial aluminum anodizing. The military standard MIL-A-8625 is most frequently used as the foundation for Type II coating. This designation is a global industry standard for commercial use in the aerospace, automotive, and medical sectors, in addition to military and defense applications.

Pros

- Corrosion protection

- Abrasion resistance

- Increased hardness

- Improved Thermal or electrical insulation

- Increased lubricity

- A much thinner coating compared to paints or powder-coat finishes

- The dimensional build-up often can be ignored for machined parts

Type III

Type III aluminum anodizing, also known as hard coat anodizing or hard anodizing, is used to improve the thermal and dialectical properties of treated aluminum products and their wear and corrosion resistance. In addition, with Type III anodizing, the capacity to retain lubricants and PTFE coatings (such as Sanford HardlubeTM) also improves. The thickness of the naturally existing oxide layer on aluminum surfaces is increased through hard coat anodizing. With Type III anodizing, natural oxide layers’ thickness, typically 2 to 3 nanometers, can be raised to or even above 50 m* (0.002″). A very regular, uniform layer is produced across the whole surface of the treated object by properly placed hard anodic coatings. The military standard Mil-A-8625 Type III category gave rise to the abbreviation Type III anodizing. * μm = micrometer (1000x the length of a nanometer).

When Is It Used?

It is used whenever the application calls for a super hard surface. The process is similar to Sulfuric Anodizing, but the layer of aluminum oxide is produced at much higher voltage and cooler temperatures.

Pros

- Highly abrasion-resistant surface (60 – 70 Rockwell C)

- Thickness ranges from 0.0005 – 0.003 inches (half build and half penetration)

- Wears better

- Corrosion resistance

Chemical Film / Alodine

To achieve outcomes similar to anodization, this process involves coating the component with alodine. When the anodizing aluminum method was created in the early 1900s, producers utilized chromic acid frequently, but today the majority of parts are anodized with sulfuric acid (Type II and Type III). There are numerous options for adding color when anodizing aluminum components. In order to color the portion, a pigment is injected into its open pores. To maintain the desired hue, the colored pigment is sealed off as it reaches the surface. This preserves the appearance of your parts by producing a visual effect that won’t wear out or be scraped off.

When Is It Used?

Chem film or Alodine is a chemical conversion coating that’s mostly used to protect aluminum from corrosion. It’s primarily used to passivate aluminum as it protects this metal and serves as a base for paint coatings. It leaves aluminum unaffected, so it’s easier to put paint over it without changing anything.

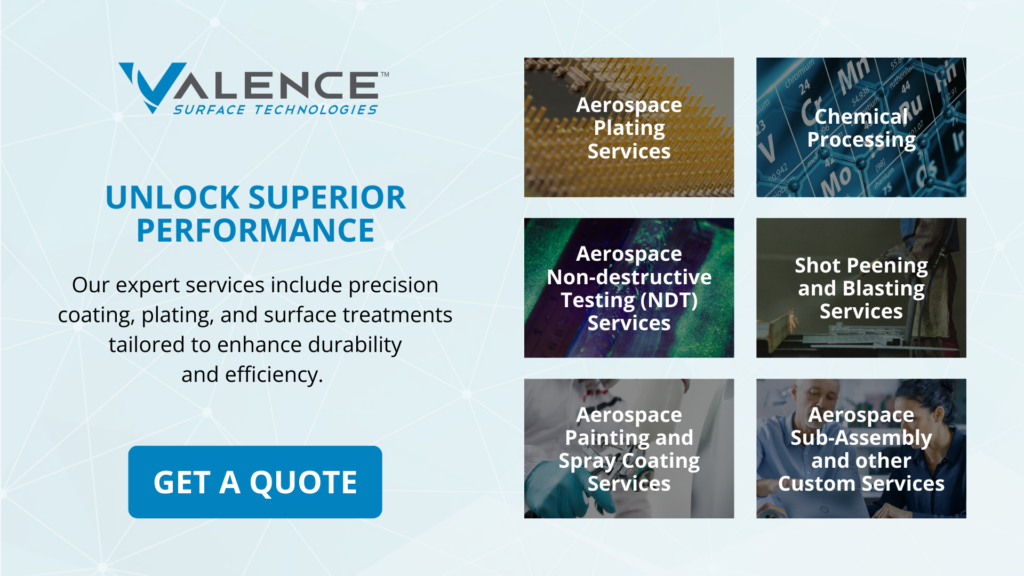

Aluminium Anodizing Services

Valence offers every variety of anodizing, including but not limited to:

Type I Anodize

- Boric Anodize – Boric-Sulfuric Acid Anodize (BSAA) is an alternative to chromic acid anodize (CAA), which builds a thin-film anodic coating and provides corrosion protection and a mechanical bond. This is a –, environmentally friendly solution.

- Tartaric Anodize – Tartaric-Sulfuric Anodize (TSA) is an alternative to chromic acid anodize (CAA), which builds a thin-film anodic coating and provides corrosion protection and a mechanical bond. This is a –, environmentally friendly solution – typically specified in Airbus programs like the A350.

- Chromic Anodize – Chromic Acid Anodize (CAA) creates the thinnest anodic while providing the same corrosion resistance as other types of anodization, such as boric or sulfuric.

Type II

- Sulfuric Anodize – Sulfuric Acid Anodize (SAA) is used when hardness and abrasion resistance is required and creates a surface that is harder than traditional chromic anodizing.

Type III

- Hard Anodize – Hardcoat anodize is created as a sulfuric acid bath, but results in a much thicker surface anode coating than traditional sulfuric acid anodizing.

Phosphoric Acid Anodize

- Phosphoric Acid Anodize – Phosphoric Acid Anodize (PAA) is most commonly used in bonding applications, providing a superior porous surface for bonding to composites.

Please contact us with any questions about our anodizing process or request a quote today.

Conclusion

The major purpose of anodizing is to improve the following properties in the metal that’s been anodized, these properties include: wear resistance, corrosion resistance, surface lubricity, heat dissipation, dielectric (non-conductive) properties, adhesion, and aesthetics. These properties are very important to businesses that employ these metals ( Aluminium and its alloys ) in service, helping them save hundreds of thousands of dollars in maintenance and component replacement costs. If your business needs functional aluminum parts that will face corrosion or wear, such as aircraft parts or consumer goods, contact us, and we’d be more than happy to help.