Aerospace Plating Services

Plating is a surface covering in which a metal is deposited on a conductive surface. The electroplate is used for corrosion inhibition, to improve solderability, to harden, to improve wearability, to reduce friction, to improve paint adhesion, to alter conductivity, or for radiation shielding.

Aerospace plating is essential to the livelihood and growth of the industry. Reliability, precision, and the use of proper materials is crucial. Valence upholds a superior quality management system throughout the metal finishing process.

AS9100 & NADCAP Approved Plating Services

Valence is the industry leader in quality for precision components in the aerospace, satellite,

We offer integrated honing and grinding capabilities to complement our cadmium and chrome plating. Using best practice plating technology, Valence Surface Technologies provides numerous plating services:

Plating Services

Cadmium Plating

Cadmium plating is a tough and versatile coating. The soft, attractive coating provides a favorable bonding surface for adhesions. It is also the preferred plating for salt-water environments due to its resistance to mold and bacteria.

Chrome Plating

Chromium plating is effective at providing excellent hardness and lubricity, reducing friction, minimizing wear, and preventing galling. In environments with corrosion or abrasion, chrome plating can withstand negative consequences on wear and tear.

Gold Plating

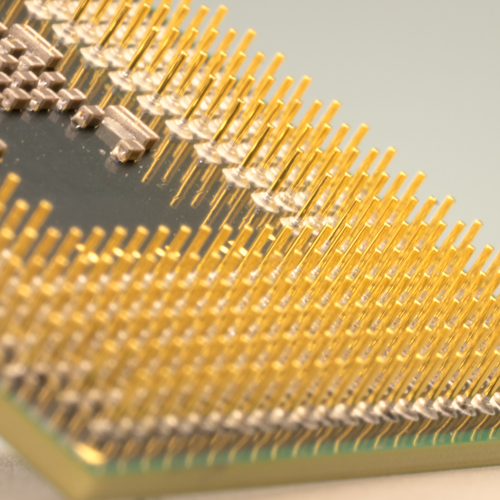

Gold plating advantages include good corrosion resistance, good solderability, and, when alloyed with cobalt, it has very good wear resistance. Gold is commonly used in electrical switch contacts, connector pins and barrels, and other applications where intermittent electrical contact occurs. It is also used as a radiation shield, in infrared reflectors and satellite electronic housings. Valence also offers immersion gold plating.

Manganese Phosphate

Manganese phosphate coating is a conversion coating, the formulation of which contains a manganese salt, phosphoric acid and an accelerator. This process is done under high temperature, and produces a surface that has good corrosion and wear resistance. Manganese phosphate coatings can retain oil and other lubricants.

Nickel Sulfamate

Nickel sulfamate is a plating process that provides a highly ductile plating surface with low internal stress. The versatility of the coating resists high temperatures, maintains high tensile strength, and provides ductility and elongation.

Ti-Cad Plating

Ti-Cad or titanium cadmium plating is a titanium cadmium combination plating that provides corrosion resistance on high strength steel applications. It significantly reduces the negative consequences of hydrogen embrittlement.

Tin Plating

Tin plating is used extensively to protect both ferrous and nonferrous surfaces. Tin is also widely used in the electronics industry because of its ability to protect the base metal from oxidation and corrosion. Depending on the base material, tin is used as a metal plating to maintain or impart solderability. Valence also offers tin lead plating.

Valence performs all of these services to the highest degree of care, with approvals for most prime, aerospace, and military specifications. Our products and services significantly enhance safety, long-term use, and consistency in the aerospace industry. View our specs here.

Plating Tank Sizes

| Valence Wichita | L | Valence Garden Grove | L |

|---|---|---|---|

| Cadmium Types I, II, III | 4′ | Copper Plate | 2′ |

| Electroless Ni-Mid | 4′ | Electroless Ni- Hi Phos | 6′ |

| Electroless Ni-Hi Phos | 2.5′ | Electroless Ni- Low phos | 3′ |

| Hard Chrome | 14′ | Electroless Ni- Mid phos | 7.5′ |

| Hard Chrome | 7′ | Gold Immersion | 2′ |

| TiCad | 4′ | Gold Plate – Grade A Type lll | 2′ |

| Gold Plate – Grade C, Type II | 3.5′ | ||

| Gold Plate – Grade D, Type I, Type II | 1.5′ | ||

| Gold Strike | 3′ | ||

| Nickel Plate – Bright /Semi Bright | 4.5′ | ||

| Nickel Plate – Semi Bright | 4.5′ | ||

| Nickel Sulfamate | 4.5′ | ||

| Silver Plate – Semi Bright | 3.5′ | ||

| Sliver Plate – Matte | 5′ | ||

| Tin Plate | 4.5′ | ||

| Tin/Lead Plate (60/40) | 3′ | ||

| Tin/Lead Plate (90/10-95/5) | 2.5′ |

Chrome Plating

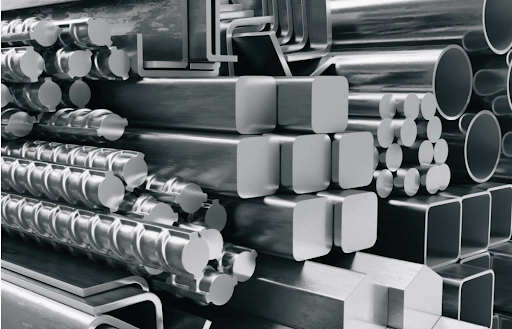

Metals like steel, titanium, aluminum, etc., have critical design and structural applications in engineering. This fact is owing to their desirable properties, which help them deliver when deployed in various applications.

However, most of these metals are deployed in harsh service conditions, gradually depleting their properties and adversely affecting their ability to deliver in service. For instance, one of the applications of steel is in the aerospace industry. This exposes it to a very harsh corrosive environment, which could lead to rust and eventual damage. The damages in this application go beyond cosmetic or aesthetic issues and will contribute to weakening the structural integrity of the steel deployed. These damages may result in more frequent replacements and increased maintenance costs.

However, other metals (e.g. chromium, nickel) have better resistance in these conditions and can be used to protect metals that are deployed in these conditions giving rise to a phenomenon called electroplating.

Electroplating is the process that adds the surface layer of a metal to another type of metal. Hence the metal added forms a protective shield to the base metal.

Now, chrome plating is an electroplating technique used to add chromium to the surface of other metals to give them better resistance to corrosion and other harsh service conditions.

What Is Chrome Plating?

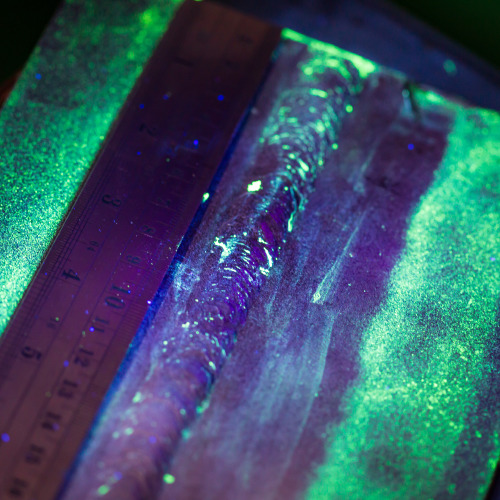

The chrome plating procedure uses an electroplating process to deposit a thin layer of chromium onto a substrate (metal or alloy).

Simply put, electroplating is accomplished by running an electric current between two electrodes that are submerged in a chromic acid-based electrolyte bath. One of the electrodes will be the substrate which is to be coated. During the flow of electricity between the two electrodes, chromium atoms are deposited in a layer on the electrode to be plated.

There are two types of chrome plating; hard plating and decorative plating.

Hard Plating

Also frequently referred to as industrial chrome. This type of plating, which is thicker than decorative plating, is used on materials that require a high level of strength and functionality. Because of its excellent lubricity and hardness, hard chromium coating is effective in decreasing friction. Its lubricity and hardness ensure that materials with this sort of coating are more robust and resistant to abrasion from wear and tear, in addition to reducing friction. Hard chrome typically has a thickness of 0.02 to 0.04mm.

Hard chrome plating has the unique ability to increase chemical inertness, particularly oxidation resistance.

Decorative Plating

Bright plating is another term for this kind of chrome plating. As a matter of fact, the name definitely reveals a lot. The chrome coatings on decorative chrome plating are often much thinner. Usually, high aesthetic potential materials are the only ones that can use them.

The material will still be protected from corrosion and abrasion by this chrome coating, but it won’t do it as well as hard chrome plating. By the way, the chrome coat’s thickness is the main distinction between them. Decorative chrome plating typically ranges in thickness from 0.002mm to 0.02mm.

It’sIt’s a unique feature of decorative chrome plating that the material must first have a shiny nickel coating before the chrome is applied. This seeks to offer the material’s reflecting qualities, smoothness, and corrosion-resistant qualities.

Beginner’s Guide To Chrome Plating

Will Chrome Plating Rust?

The corrosion of a metal results in rust. An element’s constituent components disintegrate and join with other elements in an electrochemical process to create a new compound. Due to the chemical differences between elements like iron and copper, there are several varieties of rust. This results in rust taking on a varied aesthetic depending on the metal in question.

Rusting of chrome is caused by three factors: the metal itself, water or moisture, and air. Rust cannot form unless all of these elements come into touch with one another.

When chromium gets wet, and the moisture is not removed right away, the water molecules begin to interact with the airborne carbon dioxide. (People breathe carbon dioxide out of their bodies and oxygen from the air in.) The chemical bonds that hold chrome together are weakened by carbonic acid, which is created when water and carbon dioxide react. The chrome begins to wear away and dissolve due to this weakening.

The water molecules disintegrate into hydrogen and oxygen at the same time. The two hydrogen molecules are released into the atmosphere, but rust is created when the oxygen molecule joins with the dissolving chrome. The name of this new substance is chromium oxide, also known as rust.

The good news is, Most chrome rust stains are removed with mild forms of acid. When the rust remover is applied to the rust, the stains become water-soluble and are now easier to clean.

Does Chrome Peel Off?

The simple answer is yes; chrome may peel off. There are principally two causes for chrome plating peeling. One is that inadequate base material pre-treatment before the plating technique results in peeling, which worsens the adhesion between the plating layer and the base metal. Another is that it happens as a result of the base metal corroding as a result of corrosive material getting between the base metal and the plating layer. Regarding the second explanation, it is probable in items where the chrome plating is applied directly to the base metal. The reason is that the chrome plating contains tiny fractures that allow corrosive material to seep through and contact the base metal. One of the recommendable measures to prevent the occurrence of peeling is to strike nickel plating in-between base metal and chrome plating to gain a crackle plating surface.

Another way to prevent this is to only patronize chrome plating companies you can trust.

The Price Of Chrome Plating

Is Chrome Plating Cheap?

The subject of whether or not chrome plating is cheap does not have a straightforward answer. Whether or not a commodity is cheap is usually dependent on its application or the capacity of the buyer; however, in engineering applications like aerospace and military hardware where the cost of maintenance and components replacement is very high. In these situations, chrome plating is a much cheaper option.

Is There An Alternative To Chrome Plating?

Yes, there are several alternatives to chrome plating; we will explore some of them while looking out for the best alternative.

Powder Coating

Traditionally, powder coating was only used as a more durable paint substitute for chassis pieces or other high-wear areas. However, thanks to advancements in technology, a nice gloss powder coat can now appear as smooth as paint.

In reality, we’ve seen a few track vehicles prepared in this manner because Powdercoat tends to endure longer in the punishing environment of racing. In addition, there are now hundreds of colors available, in addition to textures and satins.

Electroless nickel plating is a practical and adaptable substitute for chrome plating. Electroless nickel plating is a very effective and long-lasting option for applications that require a uniform and non-conductive plating solution. When compared to chrome plating, which is an electromechanical process, electroless plating is fundamentally different. Electroless nickel plating is more cost-effective than the chemical-intensive chrome plating procedure because it is both a more flexible and even plating solution and also uses less controlled chemicals. With a melting point of roughly 1,600°F, our electroless nickel plating produces a plating that is incredibly heat resistant and a great choice for hot situations.

Electroless Nickel Plating is the best alternative to chrome plating for various reasons. Nickel plating is a cost-effective and extremely viable alternative to chrome plating. It is corrosion-resistant, offers excellent wear, and can be fortified by extreme heat treatments. Alloyed with other metals such as tin or tungsten, nickel electroplating delivers exceptional resistance to the elements, hardness, and conductivity that lends itself to numerous applications.

The Aerospace and Electronics industries use electroless nickel finishing for many reasons. It covers very uniformly, reducing after plating machining. It has good corrosion resistance when comparing it to other nickel coatings of the same thickness.

Chrome Plating Alternatives

What Is Better, Chrome Or Chrome Plated?

Chrome (or chromium) is a naturally occurring transition metal that is hard and corrosion-resistant. A chrome-plated metal, which you may see as decorative trim on cars and motorcycles or hardened tools used for industrial processes, is an electroplated layer of chromium over another metal.

Is Chrome Plating Better Than Stainless Steel?

In order to answer this, it is important to differentiate between chrome plating and stainless steel.

What Is Chrome Steel?

Any form of steel that has been combined with chromium in an effort to avoid rusting is known as chrome plating steel. This kind of steel has undergone the chrome plating procedure.

A specified amount of chromium is put to the surface of the steel metal through chrome plating.

The end result is a glossy steel metal that has a pleasing appearance to the eye. In addition to its aesthetic value, chrome plating also has some defensive qualities. It shields the steel against rust and corrosion.

What Is Stainless Steel?

Steel that has been mixed with other elements like chromium, carbon, molybdenum, nickel, silicon, and aluminum forms stainless steel, a type of metal alloy.

Different grades of stainless steel are produced by combining these elements at specific ratios. For instance, 10% nickel and 12% nickel are both present in some steels.

The qualities of the two types of stainless steel cannot be expected to be the same.

The addition of nickel makes stainless steel stronger. The steel is resistant to rust and scratches. Additionally, rust won’t adhere to stainless steel.

Durability: Chrome Plating Vs. Stainless Steel

Does chrome have a longer lifespan than stainless steel? If properly maintained, chrome steel can last you for a very long time. If used properly and in the appropriate setting, it is durable.

Dry environments are the best conditions for chrome steel. Additionally, there shouldn’t be any substances in the area that could lead to chemical or crevice corrosion.

Once the chrome steel has been damaged, the likelihood that it will begin to rust is very high. The surface of chrome steel is permeable to a wide variety of objects. They consist of metal tools, doorway, and clamping attachments. Once rusting has started, it can quickly spread beneath the chrome coating.

In conclusion, chromium steel is not entirely dependable in terms of durability.

Stainless steel, on the other hand, has unmistakably established itself as one of the strongest metals. I won’t be harmed by rust or corrosion and will continue to serve you for many years.

Due to the endurance of stainless steel, products produced with it are frequently pricey. This feature also makes it perfect for those demanding and dangerous applications in addition to a wide range of uses.

Aesthetic Value: Chromium Plating vs. Stainless Steel

Chromium plating produces a more attractive and shiny finish than stainless steel. Hence, it is the winner in this department.

Is Chromium Steel Better Than Stainless Steel?

An appropriate answer to this would depend on the nature of the application intended. There are some situations where using stainless steel is preferable over chrome plating on things. Instead of chrome coating, stainless steel is more resilient. But chrome plating gives the object a far greater shine.

In contrast to chrome plating, stainless steel hardware doesn’t show fingerprints and won’t rust. In essence, chrome plating is less expensive than stainless steel, and it also makes the item lighter.

Pros And Cons Of Plating

Pros

- Shiny and attractive finish

- Less expensive than stainless steel

- Has elements of modernity

- Durable if used correctly

Cons

- Requires regular maintenance so as to retain its shiny look

- Can be easily scratched

- Not as durable as the stainless steel

- Shows fingerprints and even dust particles

Plating Services

Our plating services include the following:

Cadmium Plating

Cadmium plating is a tough and versatile coating. The soft, attractive coating provides a favorable bonding surface for adhesions. It is also the preferred plating for salt-water environments due to its resistance to mold and bacteria.

Chrome Plating

Chromium plating is effective at providing excellent hardness and lubricity, reducing friction, minimizing wear, and preventing galling. In environments with corrosion or abrasion, chrome plating can withstand the negative consequences of wear and tear.

Copper Plating

Copperplate has high electrical conductivity, exceeded only by silver plating. Copper is an excellent and inexpensive coating for many different uses that require conductivity or solderability. As a result of malleability and perfect adhesion, copper can maintain adhesion and serve as a base for added coating and plating.

Electroless Nickel Plating

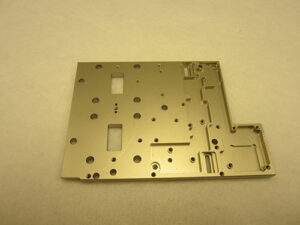

Electroless nickel plating is a unique process that uses heat and a unique chemical bath to create the nickel without the use of any electrical current. Since electroless nickel finishing does not use electricity, the coating created by the process is very uniform across the entire surface of the part, even parts with complex geometry. Threads and close tolerance features can be plated precisely without edge build-up.

Gold Plating

Gold plating advantages include good corrosion resistance and good solderability, and when alloyed with cobalt, it has very good wear resistance. Gold is commonly used in electrical switch contacts, connector pins and barrels, and other applications where intermittent electrical contact occurs. It is also used as a radiation shield in infrared reflectors and electronic satellite housings. Valence also offers immersion gold plating.

Manganese Phosphate

Manganese phosphate coating is a conversion coating, the formulation of which contains a manganese salt, phosphoric acid, and an accelerator. This process is done under high temperature and produces a surface that has good corrosion and wears resistance. Manganese phosphate coatings can retain oil and other lubricants.

Nickel Plating

Nickel plating provides exceptional hardness and corrosion/wear resistance. Nickel is one of the four ferromagnetic materials at room temperature and is a fairly active element. However, nickel deposits are slow to react in standard atmospheric environments due to the formation of a protective oxide surface providing excellent corrosion performance on most products.

Nickel Sulfamate

Nickel sulfamate is a plating process that provides a highly ductile plating surface with low internal stress. The versatility of the coating resists high temperatures, maintains high tensile strength, and provides ductility and elongation.

Silver Plating

Silver is also the best heat conductor of all metal plating materials and offers great solderability. Due to silver’s conductivity, the microwave and satellite industries use it to carry high-frequency signals and reduce the amount of heat generated compared with copper. Silver’sSilver’s lubricity and high-temperature resistance allow engine manufacturers to use silver in place of lubricants. It is used on bearing surfaces and anti-galling applications.

Ti-Cad Plating

Ti-Cad or titanium cadmium plating is a titanium cadmium combination plating that provides corrosion resistance on high-strength steel applications. It significantly reduces the negative consequences of hydrogen embrittlement.

Tin Plating

Tin plating is used extensively to protect both ferrous and nonferrous surfaces. Tin is also widely used in the electronics industry because of its ability to protect the base metal from oxidation and corrosion. Depending on the base material, tin is used as a metal plating to maintain or impart solderability. Valence also offers tin-lead plating.

Conclusion

While chrome plating has been deemed expensive, it certainly will give value for money when done correctly. Chrome plating, when done correctly, will save you a lot of dollars in maintenance and component replacement costs. Contact Valence today to get a quality chrome plating service.

Electroless Nickel Plating

Electroless nickel plating is used in the aerospace and electronics industries for many reasons. It covers very uniformly, reducing after plating machining. In addition, it has good corrosion resistance compared to nickel coatings of the same thickness. The oil and gas industry uses electroless nickel for its hardness and exceptional corrosion and resistance in that working environment.

In the industrial plating field, many companies use low-phosphorus electroless nickel to replace chrome plating. This can reduce costs by either reducing or eliminating post-plate grinding processes.

What Is Electroless Nickel Plating?

The autocatalytic chemical reduction of a nickel-alloy coating used for surface finishing (most frequently Nickel Phosphorus) results in Electroless Nickel Plating (ENP). The electric current typically used in electroplating is not used to complete this process. Instead, nickel ions are reduced with a chemical reducing agent, like sodium hypophosphite, to form ENP, which is then deposited.

The Nickel-Phosphorus alloy, which usually contains between 2% and 14% phosphorus, is deposited in a very even layer via the ENP method. The advantages of this coating for parts include resistance to corrosion, enhanced hardness, resistance to wear, and an anti-galling surface. In addition, the coating becomes amorphous at higher phosphorus concentrations, implying that no grain boundaries could serve as corrosion initiation sites. This makes the

coating perfect for protecting against corrosion.

Types Of Electroless Nickel Plating

There are different types of electroless nickel plating based on the application intended. They are:

Electroless Nickel: Corrosion Protective Finishes

- Low Phosphorus Electroless Nickel

- Mid-Phosphorus Electroless Nickel

- High Phosphorus Electroless Nickel

Electroless Nickel: Wear Resisting Finishes

- Boron Electroless Nickel

- Composite Electroless Nickel Coatings

- Carbides/Diamonds

- Polymers

Low Phosphorus Electroless Nickel

This electroless nickel bath, which has up to 5% phosphor, was created to withstand conditions with higher temperatures to provide enhanced hardness and reduced wear. It also inhibits improved solderability and increased electrical conductivity due to the low level of alloyed phosphor.

When exposed to acidic conditions, corrosion protection is inadequate compared to good protection in high pH (alkaline) situations, such as the chemical production of caustic soda and chlorine. Compressive stress is produced by this alloy, reducing the likelihood of fatigue failure in steel alloys. Comparing this to deposits of boron electroless nickel, it is a more affordable option.

Mid-Phosphorus Electroless Nickel

Mid-phosphorus electroless nickel offers moderate resistance to corrosion and wear and contains 5% to 9% phosphor. Typically, this coating is bright. Compared to alternative electroless nickel bath formulations, the bath is the most cost-effective.

It is an excellent option for restoring the tolerance of undersized parts. The fact that this bath deposits a modest amount of tensile stress onto steel is a major issue.

High Phosphorus Electroless Steel

Since they create a truly amorphous (glass-like) surface devoid of any crystalline structures, high phosphorous baths—defined as having above 10% phosphor—form the ideal deposit for the most corrosive atmospheres. They normally do not have deposits that are more than 13% phosphor. High phosphorus electroless nickel is an excellent choice for electronics that need shielding properties to prevent interference from other electronic equipment because it is fully non-magnetic as plated.

Boron Electroless Nickel

0.5% to 5% of the electroless nickel baths include boron. Boron electroless nickel coatings can be divided into two major categories. The first class is designed for usage in the electronics industry and has lower levels of boron (0.5% to 3%) for increased solderability and conductivity. Due to their enhanced hardness and wear resistance compared to phosphorus electroless nickel coatings, the second class of these coatings is used. As plated, the high boron electroless nickel (3-5%) coating is as hard as chrome, but it can be heat treated even harder. The automotive and aerospace industries primarily utilize this second class of boron electroless nickel coating for replacing chrome plating.

However, boron electroless nickel coatings are a poor choice for corrosion protection compared to phosphorus electroless nickel coatings because they have higher internal deposit stress, creating more porosity.

Composite Electroless Nickel Coatings

By adding particles to the bath, which then become occluded (deposited) with the nickel alloy, electroless nickel composite coatings are produced. The diameter of these particles varies from 0.5 to 10 um (20 to 400 u”). Particle content in the typical composite electroless nickel coating ranges from 10% to 30%.

These composite coatings can incorporate both hard and soft particles in one uniform coating and work well with any matrix electroless nickel baths. The novel electroless nickel matrix’s potential results will depend on the volume ratio of the hard and soft particles as well as the technique used.

Carbides/Diamonds

Minerals and ceramics are extremely durable and frequently practically unbreakable. Since they have very high hardness values and very high melting temperatures, they make a wonderful choice because they lessen the abrasion and wear loss of the overall electroless nickel composite coating. Composite finishes are as harsh and lifeless as plating.

Grinding and buffing done after plating could enhance the aesthetics. In comparison to boron and phosphorus electroless nickel plating alone, these coatings cost more (see table below). Aluminum oxide, silicon carbide, tungsten carbide, and, in extremely rare circumstances, diamonds or other mined minerals are a few examples of the different sorts of particles.

Polymers

Fluorocarbon-based polymers are used to minimize wear and friction on a part. The range of particle composition by volume for the majority of electroless nickel composite polymer coatings is 10 to 30%. These polymers can be equally distributed across the nickel covering and occluded within it. When plated, the coating appears matte gray to chalk white.

TeflonTM is the most widely used fluorocarbon coating. The range of particle sizes is the same as that of hard particle sizes. Good release and anti-galling qualities are produced by these coatings. While some fluorocarbons, like Teflon, have greater melting points closer to 1000° C (1832° F), the majority of polymers have significantly lower melting points than hard particles and start to melt at roughly 330° C (626° F).

Electroless Vs. Electrolytic Nickel Plating

We have already described what electroless plating is. To make a comparison between electroless and electrolytic nickel plating, we need to define what electrolytic nickel plating is.

What Is Electrolytic Nickel Plating?

Cleaning and pretreating the substrate are the first steps in electrolytic plating, just like in electroless nickel plating. The item is then submerged in a bath of positively charged nickel and a conductive base. After the object has been immersed, the solution is given an external electrical current or rectifier.

The plating procedure is finished when electricity charges the nickel anodes, causing them to release ions that adhere to the substrate’s surface.

Advantages Of Electroless Nickel Plating Over Electrolytic Nickel Plating

More Uniform Deposit Thickness

With tolerances of +/-.0001 inches, electroless nickel plating is more accurate than electrolytic plating. The “dog bone effect,” which happens when too many amps per square foot are applied during electrolytic plating and results in an uneven deposit, can be avoided by using it to produce complicated geometries.

Superior Corrosion Resistance

The addition of phosphorus to the solution improves ENP’s resistance to corrosion.

Improved EMI Shielding

Additionally, phosphorus has magnetic qualities that enable metal finishers to regulate the amount of electromagnetic interference surrounding the substrate. For applications that involve electronics, this characteristic has been shown to be essential.

Additional Hardness and Durability

Heat treatment of ENP deposits can increase their hardness to 90% of that of chromium. As-plated, low-phosphorus ENP coatings have a Rockwell scale (Rc) rating of up to 63. Comparatively, the as-plated hardness of type II brilliant nickel deposits produced by electrolytic plating is 50+ Rc.

Enhanced Lubricity

Additionally, electroless nickel plating reduces surface scarring and friction with other materials, improving lubricity.

Increased Ductility

Compared to conventional nickel coating, ENP is more ductile, making it less prone to shatter, break, or crack under pressure. However, Type I pure nickel plating offers a comparable degree of ductility and is capable of exceeding AMS2424 standards set by SAE International.

Greater Coating Versatility

The thickness of the layer can be almost any size with electroless nickel plating, and it can be applied to almost any metallic substrate.

Salvageability

ENP is a great option for materials that will eventually be salvaged.

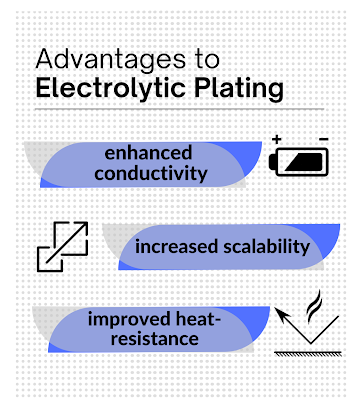

Advantages Of Electrolytic Nickel Plating Over Electroless Nickel Plating

Material Purity

While electroless nickel plating needs phosphorus, electrolytic plating can be created entirely from nickel. Other metal materials, like copper, for instance, can be used in the plating process.

Increased Scalability

Electrolytic plating can provide higher production quantities with shorter lead times and is typically less expensive than electroless nickel plating, making it a marginally more productive technique.

Enhanced Conductivity

Compared to electroless nickel plating, a higher nickel content offers improved conductivity.

Improved Heat-Resistance

Nickel deposits can resist temperatures of up to 1,832°F after processing.

What Is It Used For?

Electroless nickel plating is versatile and has many benefits. It imparts hardness to the surface and protects parts from corrosion, abrasion, and natural wear for all kinds of applications under various situations. The following industries are the ones that employ electroless nickel plating the most.

- Aerospace

- Construction

- Electronics

- Engineering

- Oil & Gas

- Automobile

What Metals Can Be Electroless Nickel Plated?

When exposed to different environmental factors and corrosive applications over time, raw metals other than precious metals can easily oxidize and corrode.

Any component’s correct design must start with a surface engineering assessment to guarantee that the final product will perform consistently for the duration of its designated service life. Corrosion can cause functional problems and shortcomings even in relatively low-stress service applications.

Galvanic corrosion, chemical assault, erosion, and other corrosive mechanisms can all be effectively countered by electroless nickel plating. Steel, copper, brass, and aluminum alloys are just a few examples of the many base metals that can receive electroless nickel plating (ENP). Electroless Nickel plating is currently utilized to promote corrosion protection performance across a diverse range of industries, including heavy equipment, oil & gas, power transmission & distribution, automotive, marine, and railway, to name a few.

What Are The Benefits Of Electroless Nickel Plating?

The Electroless Nickel Plating process offers various advantages over traditional electroplating that make it a reliable surface finishing treatment:

Corrosion Protection

Compared to electroplated nickel, electroless nickel is less porous, making it highly hard and resistant to typical corrosives such as salt water, carbon dioxide, oxygen, and hydrogen sulfide.

Cost-Efficient

Since the coating is produced using a precise and effective method without the need for energy, it is cost-effective for a variety of applications. This durable, high-quality finish can be produced for less money upfront and with less equipment than traditional electroplating. The finish adds to cost savings over the equipment’s lifetime by extending the service life of parts.

Uniformity

An extremely even coating is achieved during the ENP process. The auto-catalytic nature of this process prevents key parts of your item from being over- or under-plated because there are no high-current or low-current zones. Engineered coatings have tight controllable thickness and no edge buildup. With this method, even complicated geometries may be coated equally.

Hardness

Low (2-4%), mid (5-9%), and high (10-14%) concentrations of phosphorus are present in several types of ENP baths. The final application determines which bath should be used. High phosphorus EN (10-14%) offers the best corrosion protection while offering the lowest amount of hardness, whereas low phosphorus EN (2-4%) offers the highest hardness while offering the lowest level of corrosion protection. The best of both worlds is offered by the mid-level phosphorus (5–9%), which many clients prefer.

Disadvantages Of Electroless Nickel Plating

To increase the adherence of the nickel and lessen internal tensions inside the nickel that has been deposited on parts that are prone to corrosion via usage, post-heat treatment may be required. Hydrogen embrittlement is still a possibility for electroless nickel-plated parts.

It’s crucial to watch out during heat-treating electroless nickel so as not to temper-soften the already-existing material.

How Much Does Electroless Plating Cost?

One of the most frequent questions we get is, “how much should electroless nickel plating cost?” What company isn’t looking for ways to save costs in today’s economy? If metal plating is necessary for your business, electroless nickel plating may provide the economical answer you’re looking for.

Unlike electroplating, which uses an electrical current or other external power sources to cover a metal surface, electroless nickel plating does not. As a result, electroless nickel plating is less expensive than electroplating since nickel is frequently less expensive to plate than costly metals like gold, platinum, and silver.

Factors Impacting Electroless Nickel Plating Costs

The features of the coating, the necessity for atmospheric protection, the required hardness and wear properties, market conditions, component availability, and the complexity of the coating process can all have a significant impact on the price of the electroless nickel matrix.

A high-end, competitive Parts Finishing now costs more due to the requirement for more synergistic specialized matrix coatings, although the price of a basic electroless nickel phosphorous matrix coating has decreased.

The most straightforward strategy to reduce electroless nickel plating expenses is generally to utilize a bath matrix made of a nickel-phosphorus alloy, provided that your firm can benefit from it and that it is compatible with the metal parts you use or produce. The most expensive electroless nickel plating is frequently required for a nickel-boron composite.

Electroless Nickel Plating Services

Valence surface technologies offer all three types of electroless nickel plating such as:

Low Phosphorus Electroless Nickel (Hard)

Low phosphorus electroless nickel plating makes use of a special bath that can make the plated layer as hard as 60 Rockwell. This bath offers a deposit that is almost as hard as Hard Chrome, with the benefit of a uniform thickness both inside and outside of complex arrangements.

Because of the uniformity of the deposit, grinding is frequently skipped after plating. Low phosphorus electroless nickel is used in the electronics industry for its weldability, solderability, and strong resistance to alkaline, corrosive conditions.

The workhorse electroless nickel is this. Over time, it has demonstrated its worth. In many situations, steel pieces that have been electroless nickel plated with medium phosphorus will behave like stainless steel.

Electroless nickel plates inside and out provide consistent entire coverage and won’t accumulate on edges or ends. Medium phosphorus electroless nickel can be toughened via heat treatment from 45 Rockwell C to 68 Rockwell C.

High Phosphorous

This finish provides maximum corrosion resistance. High Phosphorus electroless nickel finishing is standard in industries that require resistance to strongly acidic corrosive environments as well as any industry that requires a pore-free finish.

Request a quote on electroless nickel plating for your application, or contact Valence Surface Technologies for more information.

Conclusion

One of the most important things to do in order to get a quality finish on electroless nickel plating is to find a reliable partner. Valence surface technologies have proven expertise to exceed your metal finishing and plating needs.

You can find out more about our electroless nickel plating service or contact us today to discuss your specification requirements.

Nickel Plating

Nickel is a popular ferromagnetic metal known for its strength, durability, and most importantly, its adhesion properties. These properties make nickel an ideal choice for plating, as it can be deposited on a variety of surfaces, including steel, brass, copper, and aluminum. It is also resistant to corrosion and temperature changes, making it perfect for automotive, aerospace, and military use.

At Valence Surface Technologies, we help different industries, including business aviation, commercial aviation, defense, space, and medical/life sciences, protect their products and components with our specialized nickel plating processes.

What Is Nickel Plating?

By definition, nickel plating is the process of depositing a thin coat of nickel metal onto the surface of another base metal. To achieve this, two main techniques can be used; electroplating and autocatalytic plating.

Nickel electroplating is where a power source is applied to the metal, causing nickel ions to be attracted and deposited onto the surface. However, in autocatalytic plating, a nickel coating is deposited onto the surface of another base metal using a controlled chemical process (reduction), which is not based on an applied current.

Until recently, nickel plating was mostly used for decorative purposes due to its shiny finish. However, it is now used in several industries for its incredible mechanical properties.

How Does It Work?

To better understand how nickel plating works, let’s first look at the properties of nickel.

Nickel is well known for its diffusion barrier capabilities and corrosion resistance. It also offers excellent abrasion and wear resistance due to its hardness, making it a great choice for protecting surfaces from environmental damage.

Therefore, when nickel is deposited onto the surface of another metal, it forms a thin layer of nickel oxide that acts as a barrier and prevents the underlying metal from rusting or corroding. In addition, it hardens and strengthens the base metal, making it less prone to damage or wear and tear.

What Metals Can Be Nickel Plated?

Nickel plating can be done on various metals, including steel, copper, titanium, brass, zinc and aluminum.

However, of these metals, zinc, steel, and aluminum require special treatment before nickel is plated. This pretreatment process involves cleaning (removing grease, oil, scale, and oxides), polishing, and phosphating the surface to ensure a strong adhesion between the base metal and the nickel plating.

Also, it’s important to note that nickel plating on plastics is commonplace among many metal finishing companies. However, plastics have to be subjected to special pretreatment processes to ensure that the nickel plating sticks to the plastic surface.

Types Of Nickel Plating

As noted earlier, nickel plating can be done in a variety of ways. Each type of plating has its own unique properties and uses, as well as its own set of pros and cons. The three most popular types of nickel plating are bright, electroless, and dull. Let’s take a closer look at each one.

Bright Nickel Plating

Bright nickel plating is an electrolytic process that deposits a highly reflective layer of nickel onto a surface. It is often used to give parts an aesthetically pleasing finish, as it has a very attractive, bright mirror-like finish that is pleasing to the eye due to its elevated sulfur content. Also, it offers excellent conductivity.

This type of nickel plating is typically used in industries where appearance and electrical conductivity are important factors, such as aerospace, automotive, and telecommunication. This type of nickel plating is ideal for parts and components such as rims, exhaust pipes, bumpers, lighting fixtures, hand tools, etc.

Pros:

- Due to its high leveling ability, bright nickel plating hides imperfections and creates an even finish on uneven surfaces.

- It also offers excellent reflectivity and electrical conductivity, making it suitable for a wide range of components that require this type of properties.

Cons:

- Although bright nickel plating has a striking appearance, it is not as corrosion-resistant as other types.

- It’s also less ductile and can’t be manipulated to create complex shapes.

- Additionally, this type of plating tends to be slightly more expensive than other processes.

Electroless Nickel Plating (ENP)

Electroless Nickel Plating (ENP)

Electroless nickel plating is an autocatalytic chemical process that deposits a layer of nickel onto the surface of a substrate. It offers superior corrosion resistance, higher strength and hardness than bright nickel plating, and excellent wear resistance.

Electroless nickel plating is used in aerospace, automotive, military, and medical industries. It’s often used to coat machined parts and components such as gears, valves, rollers and bearings. Also, it’s used in printed circuit boards and household items, including bath and shower fixtures.

Pros:

- Electroless nickel plating provides an even coating on parts with tight tolerance or complex geometries. This makes it a perfect choice for a wide range of components, from tiny medical instruments to larger machine parts.

- Not only can ENP be applied on metal substrates, but also on plastic parts (so long as they are pretreated first).

- And due to its superior corrosion resistance, ENP gives components an extended life span and protection against wear and tear.

Cons:

- As electroless nickel baths age, contaminants may build up, which can have a detrimental effect on the quality of the deposited nickel layer.

- It also requires pretreatment and a more complex plating process than other types of plating, which can potentially add to the cost.

Dull Nickel Plating

As its name suggests, dull nickel plating yields a dull matte finish. It is also an electrolytic process that deposits a thin layer of nickel onto the surface of a substrate. This type of nickel plating offers excellent malleability and hard-wearing properties on the plating substrates.

Dull nickel plating is typically used in industries such as automotive and aerospace. It’s often used to coat machine parts and components where movement is involved, such as flywheels and springs.

Pros:

- Dull nickel plating offers a coat that can build up thickness quickly, making it an excellent choice for applications where abrasion resistance is a must.

- It also offers superior epoxy bonding, welding, brazing, and soldering properties, making it suitable for various applications.

Cons:

- Although dull nickel plating provides excellent resistance to abrasion, it is not as corrosion-resistant as ENP.

Image alt text : types of nickel plating

What Is The Nickel Plating Process?

As noted earlier, nickel plating is the process of applying a thin layer of nickel onto the surface of a substrate. This is done using two techniques: electrolytic plating and electroless plating. Let’s take a closer look at the steps involved in each process.

Nickel Plating Steps

Electrolytic Nickel Plating

Step 1: Preparation

The first step involves pretreatment and preparation of the substrates. This step is important for the long-term integrity of the plated surface.

Depending on the material you’re working with, this step may involve cleaning, rinsing, degreasing, abrading or polishing. It’s also a good idea to check for any signs of corrosion or other issues that could interfere with the plating.

This helps ensure the substrate is free from all harmful contaminants, oils, and greases that may hinder the plating process.

Step 2: Station Set Up

Next, you need to set up an electroplating station. This involves setting up the power supply, an anode, a cathode, and the tank containing the plating solution.

The anode provides the ions to be deposited, while the cathode receives them. Have everything checked and double-checked to ensure it is working correctly and that you are using the correct plating solution.

Step 3: Plating The Substrate

Once the station is ready, it’s time to start plating. Begin by hanging the substrate to the cathode. Proceed by dipping the anode into the plating solution and switching on the power supply.

As current flows through the solution, the anode oxidizes, forming positively charged ions, which are then attracted to the cathode and form a thin layer of metal on the substrate.

It’s important to note that the thickness of the plating layer will depend on the amount of current that passes through the solution and the amount of time you will leave your substrate in the solution.

Step 4: Clean-Up And Post-Treatment

Finally, turn off the power supply and remove the substrate from the plating solution. Rinse it off and clean it using post-treatment cleansers. It’s also important to inspect the substrate for any signs of defects or flaws that could compromise the integrity of the plated layer.

Electroless Plating

Step 1: Preparation

The first step involves pretreatment and preparation of the substrates. The substrates are submerged in a series of chemical baths (pretreatment baths), such as degreasers.

This prepares the surface for electroless nickel plating by cleaning it of any contaminants, providing a clean surface for the plating to adhere.

Step 2: Activation

Once the substrate is pretreated and cleaned, it needs to be activated so that the ENP can adhere. The activation process is done by submerging the substrate in an activating solution (acid etch solution) which etches the surface and prepares it for plating.

Step 3: Plating

The third step is the actual electroless nickel plating. During this process, the substrate is submerged in an ENP bath containing a mixture of chemicals and nickel salts. As the substrate is submerged in this bath, a chemical reaction occurs, causing the nickel to adhere to the substrate.

Step 4: Clean-Up And Inspection

Once the substrate is plated, it needs to be rinsed and cleaned. This process removes any excess plating solution or contaminants which may have been left behind during the plating process. It also helps to give the finished product a smooth, clean finish.

Once the substrate is cleaned, it is inspected for any defects. If any are found, the plating process needs to be repeated until a satisfactory result is achieved.

Benefits Of Nickel Plating

Nickel plating has several benefits, all of which stem from the incredible properties of nickel. These benefits include:

Increased Durability

Nickel plating provides a hard layer of protection against corrosion and abrasion, making it a great choice for items that need to last.

Improved Appearance

The shiny and reflective qualities of nickel plating can improve the aesthetic of any item, making it look more attractive.

Solderability

Nickel plating makes soldering easier since it can better tolerate high temperatures while still maintaining its corrosion-resistance property.

Increased Lubricity

Nickel plating makes metal surfaces much smoother and reduces friction, meaning it’s perfect for items that need to move without obstruction.

Reduced Porosity

Nickel plating creates a stronger bond between the substrate and coating, making it harder for contaminants to penetrate.

Disadvantages Of Nickel Plating

As with most things, there are also some drawbacks to consider when opting for nickel plating. These include:

Cost

Nickel plating is a relatively expensive process. It involves a complex setup and requires additional chemicals to complete the process.

Wastage

The plating process can sometimes result in wasted material, which can be costly. In the ENP process, the chemical bath needs to be regularly changed to ensure optimal results. Not only is this a wasteful process, but it can result in hazardous waste, which could be a potential hazard for people and the environment.

Fragility

The nickel coating is hard but brittle, making it prone to cracking, especially under extreme temperatures.

Nickel Plating Services

Different metal finishing companies offer different nickel plating services based on specific needs and applications. However, at Valence Surface Technologies, we offer the following nickel plating services:

Matte Low-Stressed Sulfamate Nickel Plating

We use this process to yield pure nickel deposits (99.9% pure) that have better elongation, ductility, and machinability. These deposits end up in a matte finish, with a slight golden cast. This plating method is commonly used in soldering, brazing, epoxy bonding, over-molding, and welding applications.

Semi-Bright Sulfamate Nickel Plating

We use this process to yield semi-bright nickel deposits that are used in places where handling would discolor matte sulfamate nickel. These deposits offer great corrosion resistance, but lower solderability compared to matte sulfamate nickel. This plating method is commonly used in shuttle turbo-pumps and photo-machined sheet stock applications.

Bright Nickel Plating

This process yields deposits that are bright and shiny in appearance. They are used as undercoats to help improve reflectivity while also providing excellent coating (which helps reduce porosity and improve corrosion resistance). In addition, they provide leveling which helps smooth out surface defects. This plating method is commonly used in automotive, aerospace, and medical applications.

How Much Do They Cost?

The cost of nickel plating can vary significantly, depending on the type of service you require and the size of your parts. At Valence Surface Technologies, we offer competitive rates that can meet your needs and budget. Request a quote today to get an exact cost estimate for your project.

Also, you can contact us for more information on our nickel plating services; we will be more than happy to help!

More From Valence Surface Technologies

There you have it – all the information you need to know about nickel plating! But that’s not all from Valence Surface Technologies. We also offer a range of other plating services, including cadmium plating, gold plating, copper plating, and more. Check out our plating services to learn more.

Also, if you have any questions or need help with nickel plating services, our experienced team is here to help. Drop us a line, and we’ll get back to you as soon as possible. With Valence Surface Technologies, you can rest easy knowing your parts are in the best hands.

Plating News

Chrome Coating: A Necessary Investment for Aerospace Components

Chrome coating is not just a crucial investment, it's a necessity for aerospace components that are exposed to harsh conditions during flight. It offers a range of benefits, including enhanced durability, corrosion resistance, and improved performance. If you want to...

Gold Plating: The Best Way To Protect Aerospace Components From Tarnish

In the aerospace industry, the significance of gold plating cannot be overstated. This process plays a crucial role in safeguarding vital components against the detrimental effects of tarnish and corrosion. Unlike alternative plating techniques, gold plating stands...

Understanding The Different Types Of Gold Plating

Gold plating serves as a renowned metal finishing strategy that incorporates a delicate gold layer onto a metal object's surface. This gold veneer delivers an array of advantages such as augmented corrosion resistance, superior electrical conductivity, enhanced heat...

Choosing The Right Finish: Anodizing Vs. Powder Coating

Choosing the appropriate finish for a project, such as anodizing or powder coating, can present quite a challenge. Both of these finishes have distinct advantages and considerations, making it crucial to fully grasp their unique characteristics to guide your...