Aerospace Sub Assembly & Other Custom Services

We offer a variety of additional Nadcap approved and AS9100 certified services.

Valence offers a variety of additional services and has the capacity to grow with your business as required. As an industry leader, we’ve invested in post-manufacturing processes to streamline our customer’s supply chain. Across the United States, we aim to be your one-stop-shop for surface finishing of aerospace, defense, and space components.

Don’t see what you’re looking for below? Contact us and we can work on a custom solution with you.

Other Services and Custom Solutions

Sub-Assembly

Valence offers simple assembly such as nutplates, fasteners, and bushing installations, and post assembly paint. Valence offers intermediate assembly operations prior to topcoat application.

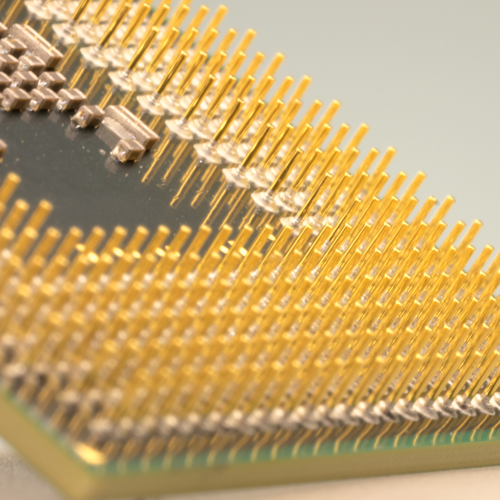

Grinding

Grinding is an abrasive machining process that uses a grinding wheel to improve the surface finish of a part. This is often used as a finishing operation post plating.

Honing

Honing is an abrasive machining process that uses an abrasive stone to create a precision surface on a metal part.

Lab Testing

Valence provides a variety of lab testing procedures and types, including hardness and conductivity, corrosion, mechanical, metallurgical and much more. We also offer additional testing such as solderability, and purity.

Part Marking

Part marking is an identification process used to serialize a part for traceability purposes, methods include tags, laser etching, digital paint marking, ink identify and more. Valence offers a variety of different part marking types to suit your application.

Vendor Managed Inventory

Valence can partner with you to manage your entire outside processing spend, including inventory management and the ability to drop ship parts directly to your customer. We can work to manage your spend with us, or even other metal finishing suppliers.

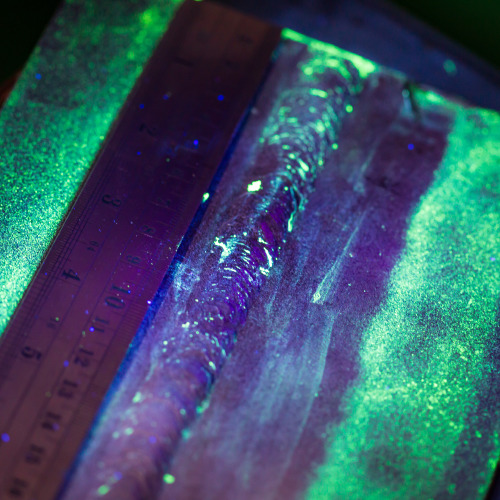

Masking

Masking is the process of covering holes and surfaces before finishing so that the treatment only affects a designated area. Valence employees have extensive experience with complex masking using various materials such as tape, glue etc.

Clean & Etch

Titanium part manufacturing results in a surface that cannot bond, and does not accept bonding primers. An alkaline peroxide etching process, also known as clean and etch, leaves a surface texture well suited to adhesive bonding and the application of bonding primers.

Stress Relief Baking

Stress relief baking minimizes stresses caused by the machining and cutting of a part during manufacture. This reduces the likelihood of unwanted dimension changes in parts that often require tight tolerances.

View our specs here.

Custom Services News

What Is A Low Earth Orbit Satellite (LEO)?

In an era where connectivity and data exchange have become fundamental pillars of our society, LEO communication satellites emerge as a game-changer. These remarkable technological marvels have revolutionized our interconnected world, delivering many services and...

The Benefits Of Precision Finishing For The Aerospace Industry

Explore the importance of precision finishing in the aerospace industry. Discover key technologies and techniques used for optimal safety and…

Magnetic Particle Inspection (NDT)

Read on to learn about magnetic particle inspection in order to detect defects and prevent any improper manufacturing before you…