Borescope Inspections: Enhancing Industry Quality And Safety

Borescope inspections serve as a preemptive measure, identifying issues before they escalate into failures. For organizations dedicated to upholding the highest standards of product integrity and operational safety, such as Valence Surface Technologies, these inspections are not just routine checks but are vital components of an overarching quality assurance strategy.

Understanding What Borescope Inspection Is

A borescope inspection is an investigative procedure employing a borescope—a specialized tool featuring a flexible or rigid tube equipped with a camera and light at one end. This device transmits images back to an operator, allowing for a close-up view of spaces that would otherwise be inaccessible. Used extensively for the internal inspection of engines, pipes, and complex machinery, borescopes can inspect for defects such as corrosion, blockages, and weld integrity without dismantling the entire system.

Types Of Borescopes

Borescope inspections are categorized based on the nature of the equipment used, each having its unique applications and advantages. Understanding these types is essential for selecting the appropriate method for a given inspection need.

Rigid Borescopes

These borescopes are straight and can’t bend. They’re best for inspecting areas that you can see directly. Their main benefit is that they give very clear images, which is great for finding small cracks or other tiny problems. However, they can’t bend to look around corners, so they’re not good for inspecting twisty areas.

Flexible Borescopes

Also called fiberscopes, these borescopes are bendy. They use fiber optics to light up dark or hidden areas. Their flexibility is useful for checking out curved or complex spaces. While they don’t show as clear images as rigid borescopes, they’re really handy for reaching places the other types can’t, making them valuable in many industries, like aerospace.

Video Borescopes

Video borescopes combine features of both rigid and flexible types. They have a camera (CCD or CMOS) on a flexible shaft and can show high-quality video or still images on a screen. They can also save these images for later. Many of these borescopes have extra features like measuring defects, changing the light level, or even 3D imaging.

Semi-Rigid Borescopes

These are a mix of rigid and flexible borescopes. They can bend a little and keep their shape during inspection. This is useful in situations where you need some bending ability but also want clear images.

The Value Of Borescope Inspection For Industry Quality And Safety

Borescope inspections are a cornerstone of maintenance and quality assurance regimes across a multitude of industries. This non-destructive technique can reveal hidden flaws and potential hazards, thereby preventing accidents, ensuring regulatory compliance, and saving time and money on extensive repairs.

Industry Applications

Borescope inspections are widely applied in industries such as aviation, power generation, oil and gas, manufacturing, and automotive. For instance, in the aviation industry, regular borescope inspections of aircraft engines and components are mandated to ensure operational safety and performance. In power plants, inspectors use borescopes to monitor turbines and boilers for signs of wear, corrosion, or damage. The automotive industry employs these inspections to assess engines and parts during manufacturing and after-market service, thereby safeguarding against future failures.

Contribution To Maintenance And Safety

Regularly scheduled borescope inspections contribute to proactive maintenance strategies by identifying issues before they lead to failures. This is critical for avoiding unscheduled downtimes which can be costly and disruptive. In safety-critical industries like aviation and energy, borescope inspections are instrumental in preventing catastrophic failures that could not only damage equipment but also threaten human lives and the environment.

The Borescope Inspection Process

Initiating a borescope inspection begins with establishing the objective: What exact internal components need to be evaluated, and what are the potential issues to look for? Once the purpose is clear, the following steps are undertaken:

- Preparation of Equipment: The appropriate type of borescope is chosen based on the inspection requirements, and the equipment is prepared, including camera adjustments and calibration if necessary.

- Accessing the Inspection Area: An entry point into the component is accessed, which may involve removing covers or panels or using existing openings like spark plug holes or inspection ports.

- Navigation and Maneuvering: The borescope is carefully inserted and navigated through the structure. For flexible or video borescopes, this involves bending and rotating the scope to ensure a comprehensive view of the area.

- Visual Examination: As the camera relays images back to the monitor, the inspector scrutinizes the visuals for any irregularities, such as cracks, corrosion, abrasions, or misalignments.

- Documentation: Any notable findings are documented. With video borescopes, capturing high-resolution images or video recordings for further analysis is possible.

- Analysis of Findings: The collected data is analyzed to understand the severity of any detected issues and determine the necessary corrective actions.

- Reporting: A detailed report is generated, often including visual evidence. This serves as a basis for maintenance decisions.

Ensuring Excellence: Borescope Inspections And Quality Assurance With Valence

Expertise And Approvals

With a foundation of over 4,500 industry approvals, Valence stands as a proven expert in precision services such as Borescope Inspections. Our accreditations bear testimony to a rigorously vetted and compliant range of capabilities essential in the aerospace industry. Choosing Valence means entrusting your components to a team that’s certified to meet the stringent standards of aerospace quality and reliability, ensuring every inspection meets exacting criteria.

Quality And Performance

Valence’s unwavering commitment to quality assures that Borescope Inspections are carried out with exceptional attention to detail. Our drive for outstanding performance ensures that inspections are not just thorough but aim to exceed industry expectations, thereby setting a benchmark in quality assurance and component integrity that clients can depend on.

Industry-Leading Company

As an industry leader in aerospace finishing, Valence brings a wealth of knowledge to Borescope Inspections, translating to advanced insights and a track record of success. Our leadership in the field ensures cutting-edge services for clients, reinforcing a reputation built on trust and excellence in the aerospace components they inspect.

Comprehensive Solutions

Valence offers a one-stop solution for aerospace finishing needs, including Borescope Inspections, simplifying the supply chain. Our broad range of services streamlines the quality assurance process, offering clients a seamless and efficient experience while dealing with a single provider for multiple demands.

Innovation And Technology

Valence’s embrace of the latest technologies ensures that our Borescope Inspections are performed using the most advanced methods and equipment. Our commitment to innovation translates into precise, detailed inspections that support the integrity and longevity of critical aerospace components.

Capacity And Investment

With substantial investment in our facilities, Valence is equipped to handle large-scale and high-volume Borescope Inspections. Our expansive processing space means they can efficiently manage extensive inspection needs, ensuring timely and quality service even for the largest aerospace components.

Customer-Centric Approach

Valence’s customer-centric approach ensures that Borescope Inspections are tailored to specific client requirements. Our service is personable and adaptive, meeting unique challenges with a focus on building long-term relationships and achieving complete customer satisfaction.

Frequently Asked Questions

What are the primary applications for borescope inspections?

Borescope inspections are used in various industries, including aviation, automotive, manufacturing, plumbing, and maintenance, for tasks such as engine inspections, weld inspections, plumbing assessments, and more.

How does a borescope work?

Borescopes consist of an insertion tube with a lens and lighting at the tip, connected to an eyepiece or display. They transmit images or video from the tip back to the viewer, enabling remote inspection.

How is the image quality in a borescope determined?

Image quality depends on factors like resolution, lighting, lens quality, and the camera if it’s a video borescope.

Can a borescope be used for both visual inspections and video recording?

Yes, many modern borescopes offer both real-time visual inspection and video recording capabilities.

What are the typical diameters of borescope insertion tubes?

Insertion tube diameters can range from a few millimeters to several centimeters, depending on the borescope’s purpose and design.

How do I choose the right borescope for my specific inspection needs?

Consider factors like the inspection environment, size of the access point, required image quality, and budget when choosing a borescope.

Are there any safety precautions I should take when using a borescope?

Safety measures include proper training, using appropriate PPE, and ensuring the borescope is suitable for the inspection environment.

What are the limitations of borescope inspections?

Limitations may include limited field of view, restricted access in some cases, and the need for skilled operators.

Can a borescope be used for remote inspections or inspections in hard-to-reach places?

Yes, one of the primary advantages of borescopes is their ability to access and inspect difficult-to-reach areas remotely.

What is the typical cost range for borescope equipment and services?

The cost can vary significantly depending on the type, quality, and features of the borescope, but they can range from hundreds to thousands of dollars. Services may also be offered by inspection professionals for a fee.

Nondestructive Testing Services

Conductivity Inspection

Conductivity inspection measures the electrical conductivity of a metal part or component. This is an in process test of chemical processing to verify the integrity and consistency of a chemical processing operation.

Hardness Testing

Hardness testing verifies the hardness of the base material, and can be used to validate that previous processes have been performed correctly. All Valence products are guaranteed to meet specified standards.

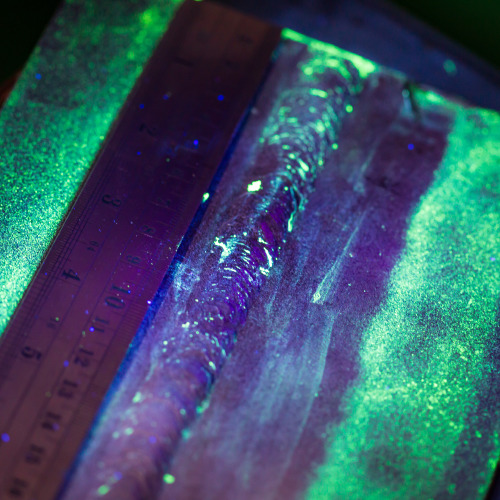

FPI (Fluorescent or Liquid Penetrant Inspection)

Fluorescent penetrant inspection is a type of dye penetrant inspection where a non-permanent fluorescent dye is applied to a non-porous part to detect cracks and defects that are invisible on sight inspection. This type of inspection is a highly efficient method to testing parts.

Magnetic Particle Inspection

Magnetic particle inspection detects surface and shallow subsurface discontinuities in ferromagnetic materials. This inspection can give immediate data and reveal errors or defects. It will prevent future leaks and other flaws.

Eddy Current Testing

Eddy current inspection uses electromagnetic induction to find and characterize surface and sub-surface defects in conductive materials. It is a highly sensitive form of testing for small surface defects, providing immediate results.

Copper Sulfate Testing

Copper sulfate testing verifies the effectiveness of, or need for passivation on a stainless steel part. This test is proficient in advanced aerospace applications.

Boroscope Inspection

Boroscope inspection allows the internal surfaces of geometrically complex components to be visually inspected for surface finish integrity. The inspection can prevent small issues in materials that potentially lead to huge losses in the long-term.

Valence performs all of these services to the highest degree of care, with approvals for most prime and military specifications. Our products and services significantly enhance safety, long-term use, and consistency in the aerospace industry. View our specs here.

NDT Capability Sizes

| Valence Eastman | L | Valence Wichita | L | Valence Grove | L | Valence Garden Grove | L | Valence Los Angeles | L | Valence Seattle | L | Valence Everett | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Eddy Current | No Limit | Hardness/Conductivity | No limit | Hardness/Conductivity | No limit | Abrasive Blast | 5' | Hardness/Conductivity | No limit | Hardness/Conductivity | No limit | Hardness/Conductivity | No limit |

| Hardness/Conductivity | No limit | Magnetic Particle Big | 6' | Penetrant | 24' | Glass Bead | 3' | Penetrant | 27' | Magnetic Particle | 4.5' | Penetrant | 30' |

| Magnetic Particle | 4.5' | Penetrant | 13' | Laser Part Mark | 4' | Penetrant | 6' | ||||||

| Penetrant | 20' | Stress Relieve Bake | 3' | ||||||||||

| Ultra Sonic Cleaning | 4' |

Nondestructive Testing News

Valence Surface Technologies Adds Nondestructive Testing (NDT) Capabilities in Southern California

GARDEN GROVE, CA MARCH 21, 2022 Valence Garden Grove Operations (formerly known as Coastline Metal Finishing) has completed the installation and commissioning of their new Nondestructive testing (NDT) line. The new line, along with inspection personnel, has passed...