Conductivity Inspection: Ensuring Aerospace Excellence

In the department of aerospace manufacturing, precision and quality cannot be compromised. Conductivity inspection is a critical aspect of quality control that ensures components meet stringent performance and safety standards. In this article, we will discuss the varied dimensions of the conductivity test and why it is pivotal for the aerospace industry.

Elevate the assurance of your aerospace components with Valence’s comprehensive conductivity inspections. Trust in our unwavering dedication to precision and quality to guarantee your projects not only meet but exceed the demanding performance and safety standards of the aerospace industry. Connect with Valence today to secure a partnership that prioritizes the peak of aerospace excellence in every inspection.

What Is A Conductivity Test?

Understanding the foundations of a conductivity test is crucial for recognizing its value in industrial processes. This test determines how well a material allows the flow of electrical current, which can be a critical indicator of the material’s composition, purity, and in many cases, its mechanical properties. It is particularly significant in industries like aerospace, automotive, and electronics where the integrity and performance of materials are paramount.

The Science Behind Conductivity Inspection In Metal Surfaces

Metals are known for their conductive properties, but not all metals conduct electricity to the same extent. Conductivity inspection delves deep into the material science to uncover hidden flaws or inconsistencies that might affect performance. Interpretation of these tests can reveal the condition and suitability of metal surfaces for their designated functions, particularly in high-stakes environments where every detail counts.

Valence’s Approach To Precision Conductivity Inspection

Valence embodies the apex of precision and innovation when it comes to conductivity inspection. Our approach is both systematic and dynamic, ensuring that every client receives unrivaled attention to detail and the highest levels of accuracy.

Tailored Testing For Every Application

We understand that different materials and applications require different testing methods. Our team designs conductivity inspection protocols that specifically cater to your project’s needs, ensuring that the testing process is comprehensive and precise, thereby delivering custom solutions that are not just effective but also resonate with the specific quality objectives of our clients.

Cutting-Edge Technology And Techniques

Investment in the latest technology and ongoing staff training ensures Valence remains ahead of the curve. Our experts use the most advanced techniques to obtain accurate conductivity readings that clients can trust, helping us to uphold our commitment to delivering only the most accurate data and analysis.

Compliance With Industry Standards

Our inspections don’t just meet the standard; they define it. Valence conducts conductivity tests in strict accordance with industry regulations, providing a level of reassurance that only a leader in the field can offer, setting the pace for others in the industry to follow.

Seamless Integration With Client Processes

Our services are designed to fit perfectly within your production or maintenance routines. This seamless integration minimizes disruption and maximizes efficiency, contributing to the smooth continuation of your operations, and it is a demonstration of how our holistic approach extends beyond testing to include the entire lifecycle of your project.

Innovations In Conductivity Measurement For Aerospace Applications

As aerospace applications evolve, so too do the methods we use to ensure their integrity. Valence is at the forefront, pushing the boundaries of existing technology to fine-tune the art of conductivity measurement.

Automated Testing For Consistency

Automation in conductivity testing ensures consistency and eliminates the potential for human error. Our automated systems are calibrated for precision, providing dependable results every time—a testament to Valence’s drive for perfection in every aspect of our service.

Data-Driven Decision Making

Data is at the core of modern aerospace engineering. Our conductivity tests yield robust datasets that inform critical decisions about material and design selection, giving our clients the confidence to make informed decisions that lead to superior aerospace components.

Enhanced Safety Protocols

Every innovation incorporates enhanced safety measures. We believe that the advancements in conductivity testing should also serve the dual purpose of elevating safety within the industry, thereby safeguarding not just the assets but also the lives that depend on the integrity of aerospace materials.

Sustainable Practices In Testing

We are committed to innovation that resonates with our responsibility towards sustainability. Our cutting-edge practices aim to reduce waste and energy consumption without compromising on quality, reinforcing our pledge to not only serve the present but also protect the future of our industry and planet.

The Essential Role Of Conductivity Testing In Aviation Safety

Safety remains the cornerstone of the aviation industry, and conductivity testing plays a vital part in ensuring that the materials used are up to the task. Here’s why this test is essential to keeping skies safe.

Material Integrity Assurance

Conductivity tests serve as a key indicator of material health and integrity. Valence leverages these tests to assure that materials are free of defects and fit for purpose. By meticulously scrutinizing materials through these conductivity tests, Valence helps build a robust foundation for the safety and reliability of aviation components.

Early Detection Of Potential Issues

Identifying potential safety issues before they become critical problems is crucial. Our conductivity testing is designed to uncover problems in their infancy, before they can affect the safety and operation of an aircraft. This proactive approach to safety, backed by Valence’s rigorous testing protocols, ensures that potential hazards are addressed well before they pose any risk to flight operations.

Compliance With Aviation Standards

The aviation sector operates under some of the most stringent standards in the industry. Conductivity testing by Valence ensures that these standards are not just met but exceeded. Our adherence to these rigorous protocols reflects our unwavering commitment to upholding and advancing the safety benchmarks within the aviation industry.

Enhanced Lifecycle Management

The insights gleaned from our conductivity tests play an important role in lifecycle management, allowing better prediction and planning for maintenance and replacements, ultimately enhancing overall safety.

Valence’s dedication to extending the operational lifespan of aerospace components through these insights exemplifies our holistic view of product safety and sustainability.

Advancing Military And Defense Readiness With Conductivity Inspection

The military and defense sectors rely on equipment that performs in the toughest of conditions. Conductivity inspection stands as an essential tool in ensuring readiness and reliability of the equipment used by our armed forces.

Mission-Critical Precision

Our approach to testing for the defense sector is executed with the precision that mission-critical components demand. This level of precision reflects our understanding of the high stakes involved, where every measurement can be the difference between success and failure in the field.

Adherence To Stringent Defense Standards

Valence’s inspections meet the rigid standards required for defense applications, ensuring that every piece of equipment can withstand the demands of service. Our rigorous testing regimen aligns perfectly with the expectations of the defense industry, where there is no room for error.

Support For National Security

Our commitment to quality and precision in conductivity testing ultimately supports national security by ensuring the dependability of critical defense technologies. Through our work, Valence plays a key role in the defense ecosystem, contributing to the strength and reliability of systems that protect nations and their citizens.

Conductivity Testing And Its Role In Space Exploration Innovations

Conductivity testing is a cornerstone in space exploration, where the robustness of materials is non-negotiable. These tests, performed with the utmost precision by Valence, are crucial for ensuring that spacecraft materials possess the necessary conductive properties to withstand the rigors of space environments. From thermal regulation to radiation shielding, the insights gained from these tests are critical to the success of every mission, informing design choices and guaranteeing the reliability of the technologies that carry humanity’s ambitions beyond our planet.

How Valence Ensures Quality Control With Thorough Conductivity Tests

Quality control is a multi-layered process demanding attention to detail and an unwavering commitment to excellence. Here is how Valence ensures that each step of the process upholds the premium quality of their conductivity tests.

Comprehensive Testing Protocols

Every step, from sample preparation to final reporting, is executed with precision following comprehensive protocols designed to capture the full scope of material properties. These protocols are not static; they evolve to incorporate the latest technical advances and client feedback, ensuring that each test is as robust as possible.

Technical Expertise At Every Level

Our technicians are not just skilled; they are masters of their trade. Valence’s team brings technical expertise that is critical to the success of our thorough conductivity tests. Their proficiency ensures that we not only meet but also exceed the complex and unique requirements of each project, assuring the highest quality in every test performed.

Continuous Improvement And Standards Review

We are continually refining our processes, ensuring our methods are not only current but ahead of industry trends. This culture of continuous improvement means that every conductivity test is performed with a forward-thinking approach, anticipating the needs and expectations of a rapidly evolving industry.

Final Validation Of Results

Before any results are delivered, they undergo a rigorous validation process. Valence’s quality control doesn’t stop at testing; it extends to ensuring the reliability of the data provided. This multi-tiered validation ensures that the results you receive are not only accurate but also operationally relevant, providing you with the certainty needed to make critical decisions.

Benefits Of Conductivity Tests

Conductivity tests bring a wealth of benefits to any industry reliant on material performance. Let’s explore some of the key advantages.

Enhanced Material Selection

The knowledge gained from conductivity tests can guide material selection, ensuring that each project starts with the right foundation. This informed selection process ultimately leads to enhanced performance, durability, and suitability of materials for specific applications, effectively aligning material properties with project requirements.

Improved Manufacturing Processes

These tests can identify inefficiencies within manufacturing processes, paving the way for improved techniques and outcomes. The insights provided by conductivity tests offer actionable intelligence that can refine production methodologies, yielding a higher quality output and an optimized manufacturing workflow.

Cost And Time Savings

By identifying potential issues early on, conductivity tests can save on both costs and time, preventing costly reworks or delays. These savings are a direct result of the predictive power of conductivity tests, which allow for proactive adjustments to be made before additional resources are expended.

Boosted Confidence In Final Products

When conductivity tests affirm material properties, manufacturers and users alike can have greater confidence in the final products, knowing that they have passed through rigorous quality control measures. This assurance builds a strong reputation for reliability and quality excellence, strengthening the trust between manufacturers, clients, and end-users.

Final Thoughts

Whether it’s enhancing material selection, refining manufacturing processes, delivering cost and time efficiency, or bolstering confidence in final products, the significance of conductivity tests spans the gamut of production and application. They are critical checkpoints on the road to exceptional product integrity, integral to industries that will not—indeed, cannot—compromise on quality.

For those of you in aerospace, defense, space exploration, or any field where material performance is paramount, consider the reassurance a comprehensive conductivity test can provide. When it comes to ensuring the safety, quality, and reliability of your components, don’t settle for less. Trust in a partner like Valence to take you beyond the mere fulfillment of standards.

Frequently Asked Questions

What are the primary industries besides aerospace that rely on conductivity tests?

Apart from aerospace, industries like automotive and electronics significantly rely on conductivity tests to ensure the quality and performance of materials used in their products.

How does conductivity testing benefit aerospace manufacturing?

Conductivity testing ensures the quality and integrity of materials used in aerospace, ensuring they meet stringent standards for performance and safety. It helps identify flaws or inconsistencies in materials that could affect their reliability in high-stakes environments.

How does Valence Surface Technologies approach precision conductivity inspection?

Valence Surface Technologies employs a systematic and dynamic approach to conductivity inspection, emphasizing attention to detail and high levels of accuracy, tailored to meet specific project needs.

Why is data-driven decision-making emphasized in conductivity testing?

Data obtained from conductivity tests assists in making informed decisions about material selection and design, offering robust insights crucial for developing superior aerospace components.

How does Valence ensure compliance with defense standards?

Valence conducts rigorous testing that aligns perfectly with the demanding standards of the defense industry, ensuring the equipment’s resilience and reliability in challenging conditions.

What are the environmental benefits of Valence Surface Technologies’ conductivity testing practices?

Valence Surface Technologies is committed to sustainability, implementing cutting-edge practices that reduce waste and energy consumption while maintaining high testing standards.

What role does conductivity testing play in lifecycle management of aerospace components?

Conductivity tests provide insights crucial for predicting maintenance needs, enhancing planning for replacements, and extending the operational lifespan of aerospace components.

Can conductivity testing identify flaws in materials before they become critical issues?

Yes, conductivity testing can identify potential flaws in materials during their early stages, preventing critical issues that might affect the safety and reliability of aerospace components.

What distinguishes Valence’s approach to conductivity testing from its competitors?

Valence’s approach focuses on tailored testing, continuous improvement, and a commitment to precision, setting them apart by delivering custom solutions with superior accuracy.

What kind of materials undergo conductivity testing in aerospace applications?

Various materials, including metals and alloys, undergo conductivity testing in aerospace applications to ensure their suitability, integrity, and performance.

Sources:

- American Society for Metals International. (2020). ASM Handbook: Volume 17 – Electrical Properties of Metals. ASM International. https://www.asminternational.org/asm-ready-reference-electrical-and-magnetic-properties-of-metals/results/-/journal_content/56/06333G/PUBLICATION/

- Society of Automotive Engineers. (2020). SAE Handbook: J1459 – Conductor and Insulation Materials for Electrical Wiring Systems. SAE International. https://www.sae.org/standards/content/j1459_202205/

- Institute of Electrical and Electronics Engineers. (2023). IEEE Standard 1645 – Standard for Test Procedures for Electrical Properties of Insulating Materials. IEEE Standards Association. https://standards.ieee.org/ieee/1276/5866/

- American Chemistry Council. (n.d.). Chemical Industry Facts and Figures. [https://www.americanchemistry.com/]

- American Society of Civil Engineers. (2018). ACI 318-14: Building Code Requirements for Structural Concrete. American Concrete Institute. https://www.concrete.org/Portals/0/Files/PDF/Previews/318-14_preview1.pdf

- Federal Aviation Administration. (2012). Advisory Circular 25-1309-1C: Aircraft Electrical Bonding and Grounding. [https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC%2025.1309-1.pdf]

- Society of Automotive Engineers International. (2016). SAE Aerospace Standard AS55048 – Conductivity Test Method for Aerospace Structural Composite Materials. SAE International. https://sms.sae.org/

- Journal of Composite Materials. (2023). https://www.asc-composites.org/. (This journal publishes articles on various aspects of composite materials testing, including conductivity.)

- National Defense Industrial Association. (2023). Defense Industry Standards. [https://www.ndia.org/]

- American Institute of Aeronautics and Astronautics. (2022). Journal of Aircraft. https://arc.aiaa.org/journal/ja. (This journal publishes articles on various aspects of aircraft design and manufacturing, including testing methods.)

- Valence Surface Technologies. (2023). Conductivity Testing Services. [https://www.valencesurfacetech.com/] (Note: This is a company website, but it provides a general overview of their services.)

- Advanced Materials & Processes. (2022). Valence Surface Technologies: Conductivity Testing for Aerospace Components. https://www.valencesurfacetech.com/ (This article specifically focuses on Valence’s approach to conductivity testing in the aerospace industry.)

Nondestructive Testing Services

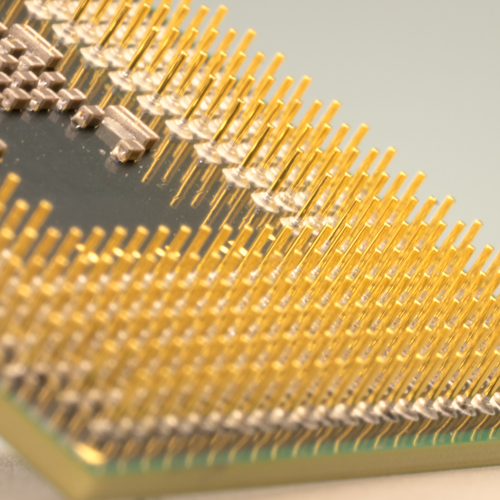

Conductivity Inspection

Conductivity inspection measures the electrical conductivity of a metal part or component. This is an in process test of chemical processing to verify the integrity and consistency of a chemical processing operation.

Hardness Testing

Hardness testing verifies the hardness of the base material, and can be used to validate that previous processes have been performed correctly. All Valence products are guaranteed to meet specified standards.

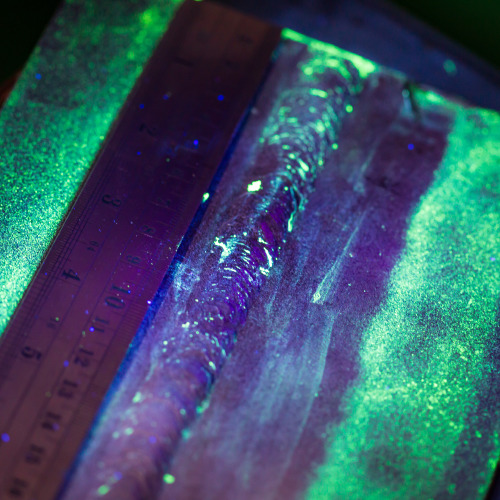

FPI (Fluorescent or Liquid Penetrant Inspection)

Fluorescent penetrant inspection is a type of dye penetrant inspection where a non-permanent fluorescent dye is applied to a non-porous part to detect cracks and defects that are invisible on sight inspection. This type of inspection is a highly efficient method to testing parts.

Magnetic Particle Inspection

Magnetic particle inspection detects surface and shallow subsurface discontinuities in ferromagnetic materials. This inspection can give immediate data and reveal errors or defects. It will prevent future leaks and other flaws.

Eddy Current Testing

Eddy current inspection uses electromagnetic induction to find and characterize surface and sub-surface defects in conductive materials. It is a highly sensitive form of testing for small surface defects, providing immediate results.

Copper Sulfate Testing

Copper sulfate testing verifies the effectiveness of, or need for passivation on a stainless steel part. This test is proficient in advanced aerospace applications.

Boroscope Inspection

Boroscope inspection allows the internal surfaces of geometrically complex components to be visually inspected for surface finish integrity. The inspection can prevent small issues in materials that potentially lead to huge losses in the long-term.

Valence performs all of these services to the highest degree of care, with approvals for most prime and military specifications. Our products and services significantly enhance safety, long-term use, and consistency in the aerospace industry. View our specs here.

NDT Capability Sizes

| Valence Eastman | L | Valence Wichita | L | Valence Grove | L | Valence Garden Grove | L | Valence Los Angeles | L | Valence Seattle | L | Valence Everett | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Eddy Current | No Limit | Hardness/Conductivity | No limit | Hardness/Conductivity | No limit | Abrasive Blast | 5' | Hardness/Conductivity | No limit | Hardness/Conductivity | No limit | Hardness/Conductivity | No limit |

| Hardness/Conductivity | No limit | Magnetic Particle Big | 6' | Penetrant | 24' | Glass Bead | 3' | Penetrant | 27' | Magnetic Particle | 4.5' | Penetrant | 30' |

| Magnetic Particle | 4.5' | Penetrant | 13' | Laser Part Mark | 4' | Penetrant | 6' | ||||||

| Penetrant | 20' | Stress Relieve Bake | 3' | ||||||||||

| Ultra Sonic Cleaning | 4' |

Nondestructive Testing News

Valence Surface Technologies Adds Nondestructive Testing (NDT) Capabilities in Southern California

GARDEN GROVE, CA MARCH 21, 2022 Valence Garden Grove Operations (formerly known as Coastline Metal Finishing) has completed the installation and commissioning of their new Nondestructive testing (NDT) line. The new line, along with inspection personnel, has passed...