Primer Undercoat

What Is A Primer Undercoat?

A primer undercoat is a preparatory coating applied to materials before the final paint or finish. This layer serves multiple purposes. This process improves paint adhesion, enhances its longevity, and offers extra protection for the underlying material. Consider it the crucial foundation that readies a canvas for a masterpiece – without it, even the brightest paint may not adhere or appear as it should.

Different Types Of Primer Undercoats And Their Uses

Choosing the right primer undercoat is crucial for ensuring the best results and durability. Here’s a look at the variety tailored to different applications:

Water-Based Primer Undercoats

Water-based primer undercoats are a smart choice for indoor projects, offering easy application and quick drying times. They are eco-friendly and emit low levels of volatile organic compounds (VOCs), which improves air quality and safety for people involved in painting. This type of undercoat is ideal for living spaces and areas where rapid job completion is critical. Water-based primers also make cleaning up easier with water, making the painting process more efficient.

Oil-Based Primer Undercoats

Oil-based primer undercoats provide a durable foundation for paint, especially suited to withstand harsh exterior conditions or areas with high traffic. These undercoats have strong adhesion, sealing porous surfaces effectively and creating a smooth, protective layer that extends the life of the topcoat. They are particularly effective in preventing tannin bleed in wood and resisting rust in metal surfaces.

Shellac-Based Primer Undercoats

Shellac-based primer undercoats are excellent at blocking persistent stains and sealing in unpleasant odors. These undercoats stick well to many surfaces and dry to a hard finish, which can be sanded to create an ultra-smooth base. They are commonly chosen for restoration projects or surfaces damaged by smoke or water, guaranteeing a clean, even look for the final paintwork.

Step-By-Step Guide To Applying Primer Undercoat Effectively

Preparing and applying a primer undercoat properly can make all the difference in the end result.

Proper Surface Preparation

The key to a successful primer undercoat application lies in the preparation of the surface. Cleaning, sanding, and addressing defects are essential to ensure the primer adheres well and provides a smooth base. It’s important to clean off dust, oils, and any loose old paint to ensure proper paint adhesion and a high-quality finish.

Choosing The Correct Primer

Selecting the appropriate primer undercoat is vital and should be based on the type of surface material and the intended topcoat. Factors such as porosity, material type, and exposure conditions should guide this choice. The correctly chosen primer will enhance paint adhesion, offer additional protection to the surface, and contribute to a more uniform and flawless topcoat appearance.

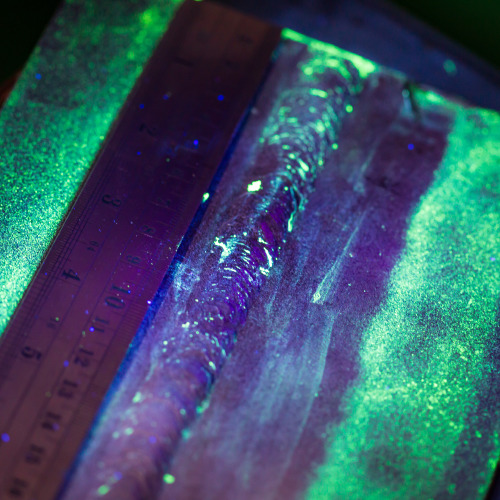

Applying The Primer Undercoat

The primer undercoat should be applied in even, consistent layers for an optimal outcome. Proper technique involves maintaining a uniform distance and speed when spraying or using straight, overlapping brush strokes when applying with a brush. It’s important to cover the entire surface thoroughly, avoiding drips or uneven patches that could lead to an inferior finish.

Allowing Adequate Drying Time

After application, it’s critical to allow the primer undercoat sufficient time to dry completely before proceeding with the topcoat. The drying time can depend on factors such as primer type, humidity, and temperature. Adequate drying ensures that the primer undercoat has set properly, providing the perfect base for a durable and visually appealing final coat.

Valence’s Approach To Primer Undercoat

Valence tailors its approach to primer undercoats, recognizing the uniqueness of each project and client’s needs.

Customization For Project Needs

Our team takes the time to understand your project’s specific challenges and environment, crafting primer undercoats that stand up to the various stresses they will encounter, be it extreme temperatures, abrasive chemicals, or the need for aesthetic finesse. This custom service guarantees that our clients’ components will get not just a suitable coating but also the best one for their specific use. It’s about finding the ideal balance between aesthetics and practicality.

Quality Materials And Products

It’s not just about meeting expectations but exceeding them. With this goal in mind, we carefully choose only the highest quality materials, making sure they meet our rigorous quality control standards.

Our research teams are dedicated to finding and testing products that are dependable, even in the toughest conditions. We know that the dependability of our primer undercoats is crucial for your project’s success, and we take this responsibility seriously, making sure you can move forward with trust in our products.

Cutting-Edge Application Technologies

At Valence, using the most recent developments in application technology is a normal part of our process. Our facilities are equipped with cutting-edge tools and machinery, allowing our expert technicians to apply primer undercoats evenly and with exact precision. Together with our thorough training and best-practice methods, we make sure each application is flawlessly performed, creating the perfect base for the next layer of coating.

Proactive Client Engagement

At Valence, open and clear communication is key to maintaining strong relationships with our clients. From the initial consultation to the completion of the project, we engage with our clients proactively, ensuring a transparent and collaborative process. We keep you involved at every stage, updating you, seeking your feedback, and adapting to any specific needs of your project as they come up. This ongoing conversation ensures that the final result matches your vision exactly and that the process is a collaborative and successful partnership.

Valence’s personalized method, which includes customization, careful material selection, use of advanced technology, and active communication, guarantees our clients a primer undercoat service of unparalleled quality, perfectly suited to the specific requirements of their projects. Valence goes beyond just delivering surface treatments. We set the standard for excellence.

Benefits Of Using A Primer Undercoat Before Painting

Enhanced Adhesion

A primer undercoat is essential for promoting strong adhesion between the substrate and the top layer of paint. The primer creates a uniform base that helps the paint adhere well, reducing the chances of it peeling or flaking off later. This is especially important for surfaces exposed to varying temperatures or heavy use, where the bond between paint layers needs to be resilient.

Smoother Paint Finish

Using a primer undercoat prepares for a perfectly smooth paint finish. The primer undercoat fills in small defects, blemishes, or pores in the surface, leading to a smooth and level area for the topcoats to apply evenly. This step is crucial for achieving a professional, clean look that’s visually appealing.

Increased Paint Durability

The protective qualities of a primer undercoat extend the lifespan of the paint job. The primer undercoat seals the surface, acting as a shield against moisture and environmental factors that could otherwise damage the paint over time. This results in a finish that retains its integrity and aesthetic appeal for years to come.

Cost-Effectiveness

Applying a primer undercoat is a strategic move for both long-term maintenance and cost-effectiveness. Applying a primer is an upfront investment that saves money in the long run by lowering the chances of needing major repairs, touch-ups, or a complete redo of the paint job later.

Frequently Asked Questions

Can I skip using a primer undercoat?

While it’s possible to skip using a primer, doing so might compromise the quality and longevity of the paint job. A primer undercoat significantly improves the overall finish and durability.

Can I use the same primer for all surfaces?

It’s essential to choose a primer suited to the specific surface material and intended topcoat for optimal performance.

Do water-based primer undercoats have any environmental benefits?

Yes, they generally have lower VOC emissions, making them environmentally friendly and safer for indoor use.

How long does a primer undercoat take to dry?

Drying times vary based on the type of primer, humidity, and temperature. It’s crucial to allow sufficient drying time for a successful topcoat application.

What happens if I paint over a primer undercoat before it’s completely dry?

Painting over a primer that hasn’t fully dried can compromise the adhesion and durability of the final coat.

Can a primer undercoat be applied over existing paint?

Yes, it can be applied over existing paint after proper surface preparation to ensure good adhesion.

Is a primer undercoat necessary for exterior painting?

Yes, especially in harsh exterior conditions or areas with high traffic, a primer undercoat is crucial for ensuring paint durability.

Can a primer undercoat cover stains or odors effectively?

Shellac-based primer undercoats are particularly effective in covering stains and sealing odors.

Can I apply a primer undercoat myself, or is professional application necessary?

While it’s possible to apply a primer undercoat yourself, professional application ensures precision and expertise, leading to better results.

Can Valence provide guidance on choosing the right primer undercoat for a specific project?

Valence offers consultation and guidance to help clients select the most suitable primer undercoat for their project needs.

Painting Services

Primer

Primer, also known as undercoat, is the preparatory coating that can be used to enhance the bond strength of a topcoat and/or improve the corrosion resistance of a part. Applying primer is a crucial first step to the lasting results.

Fuel Tank Coating

Fuel tank coating is a specialty coating applied to the interior of aircraft fuel tanks that protects against corrosion from fuel contaminants. The coating allows fuel tanks to meet industry standards for longer durations.

Adhesive Bond Primer

Topcoat

Topcoat is the final coating on a part often used for cosmetic purposes. However, it often has application specific properties, such as reflectivity, conductivity, etc. The topcoat provides durability and resistance to harmful materials that will cause parts to deteriorate.

Anti-Chafe

Anti-Chafe topcoats are specific coatings that are primarily used on surfaces where abrasion resistance, low friction and impact resistance are required to reduce chafing and wear. This specific topcoat serves as a defense in harmful environments.

Dry Film Lube

Dry film lube is a dry lubricant coating that reduces friction on surfaces sliding against each other. It offers operation at higher temperatures than other lubricants.

Sol-Gel

Sol-Gel is a process of creating metal oxides when applied to a part using metal alkoxides. The sol-gel is in high demand as it allows adhesive bonding of titanium and corrosion resistant alloys.

Zinc Spray

Zinc spray, or zinc chromate spray is a primer with corrosion inhibiting properties, commonly used on aluminum aircraft or spacecraft components. It is a high quality aerospace plating technique.

Digital Masking

Valence performs all of these services to the highest degree of care, with approvals for most prime and military specifications. Our products and services significantly enhance safety, long-term use, and consistency in the aerospace industry. View our specs here.

Painting Capability Sizes

| Valence Eastman | L | Valence Wichita | L | Valence Grove | L | Valence Los Angeles | L | Valence Seattle | L | Valence Everett | L | Valence Garden Grove | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bond Primer | 20' | Bond Primer | 16' | Bond Primer | 24' | Bond Primer | 27' | Bond Primer | 6' | Bond Primer | 30' | Bond Primer | 10' |

| Dry Lube | 20' | Dry Lube | 16' | Dry Lube | 10' | Dry Lube | 27' | Dry Lube | 2.5' | Dry Lube | 30' | Paint | 10' |

| Fuel Tank Coating | 20' | Fuel Tank Coating | 16' | Fuel Tank Coating | 24' | Fuel Tank Coating | 27' | Fuel Tank Coating | 6' | Fuel Tank Coating | 30' | ||

| Primer | 20' | Primer | 16' | Primer | 24' | Primer | 27' | Prime and Topcoat | 6' | Primer | 30' | ||

| Topcoat | 20' | Sol Gel | 16' | Topcoat | 24' | Topcoat | 27' | Sol Gel | 4' | Topcoat | 30' | ||

| Sol Gel | 20' | Topcoat | 24' | Sol Gel | 24' | Sol Gel | 27' | Sol Gel | 30' | ||||

| Zinc Spray | 12' |

Painting & Spray Coating News

What Are Thermal Control Coatings (TCC) For Satellites?

As satellites venture through the unforgiving expanse of space, they face a formidable challenge: the extreme temperatures that fluctuate between scorching heat and icy cold. To conquer this cosmic thermal battleground, satellites enlist the aid of a remarkable ally:...

Thermal Control Coatings: A Necessary Component For Satellites

Discover why thermal control coatings are essential for safeguarding satellites against extreme temperatures and may guarantee their optimal performance…

Passivation Standards ASTM A967

Stainless steel, having found applications in different industries is an important part of our daily lives. In the aerospace and even many manufacturing industries, stainless steel has found application and is a very important material. It is known to have better...

What Is Passivation: The Secret To Long-Lasting Metal Protection

Understand the ABCs of passivation and learn how it extends the life of metal components by protecting them from corrosion and oxidation …