Cadmium Plating Services

In the field of aerospace technology, the pursuit of excellence in surface treatments is paramount. Cadmium plating services stand at the forefront of this endeavor, offering a unique blend of corrosion resistance, ductility, and distinct levels of conductivity. As we explore the intricacies of cadmium plating, it’s crucial to align with industry leaders like Valence Surface Tech, who provide elite services that ensure aerospace components achieve their highest possible performance standards.

Ready to enhance your components with superior cadmium plating? Start plating today with Valence Surface Technologies and secure the performance edge for your aerospace and defense applications. Get a quote now!

Understanding Cadmium Plating

Cadmium plating is a protective coating process that uses cadmium to deposition onto metal substrates, offering superior corrosion resistance, durability, and a barrier against environmental reactions. It creates an insulator between the material and its surroundings, preventing oxygen and moisture from contacting it. Cadmium plating is lightweight and easy to apply, making it suitable for various aerospace components like engine parts and landing gear, where durability and strength are crucial.

The Cadmium Plating Process

The process requires meticulous execution and control to meet strict industry standards. Below are the essential steps that comprise the cadmium plating process:

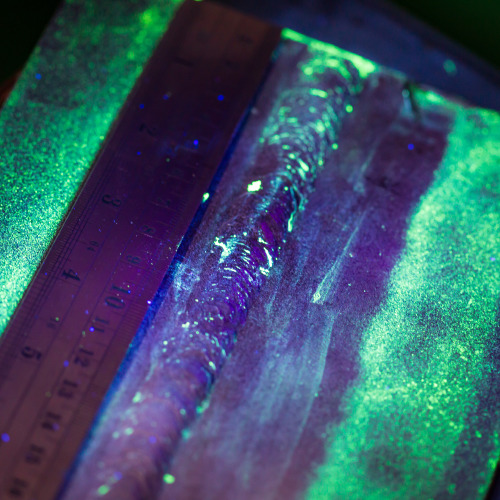

- Surface Preparation: Parts are cleaned to remove oils, debris, and surface imperfections for optimal plating adhesion.

- Bath Immersion: The cleaned parts are immersed in a tank containing an electrolytic solution with cadmium.

- Electroplating: Electrical current is applied to transfer cadmium ions from the solution onto the metal surface.

- Rinsing And Drying: The electroplated parts are thoroughly rinsed to remove any remaining solution and then dried.

- Quality Inspection: The finished parts are inspected for plating thickness, quality, and adherence to specifications.

Applications In Aerospace and Defense

Cadmium plating finds its most critical applications in the highly specialized fields of aerospace and defense, where exceptional performance and reliability are non-negotiable. The process is fundamental in extending the lifespan and enhancing the functionality of vital components that must withstand extreme operational stresses and corrosive environments.1 Below are the top five applications of cadmium plating in aerospace and defense:

Aircraft Fasteners: Cadmium plating is used to protect bolts, nuts, and screws from corrosion and to prevent seizing due to metal-on-metal contact.

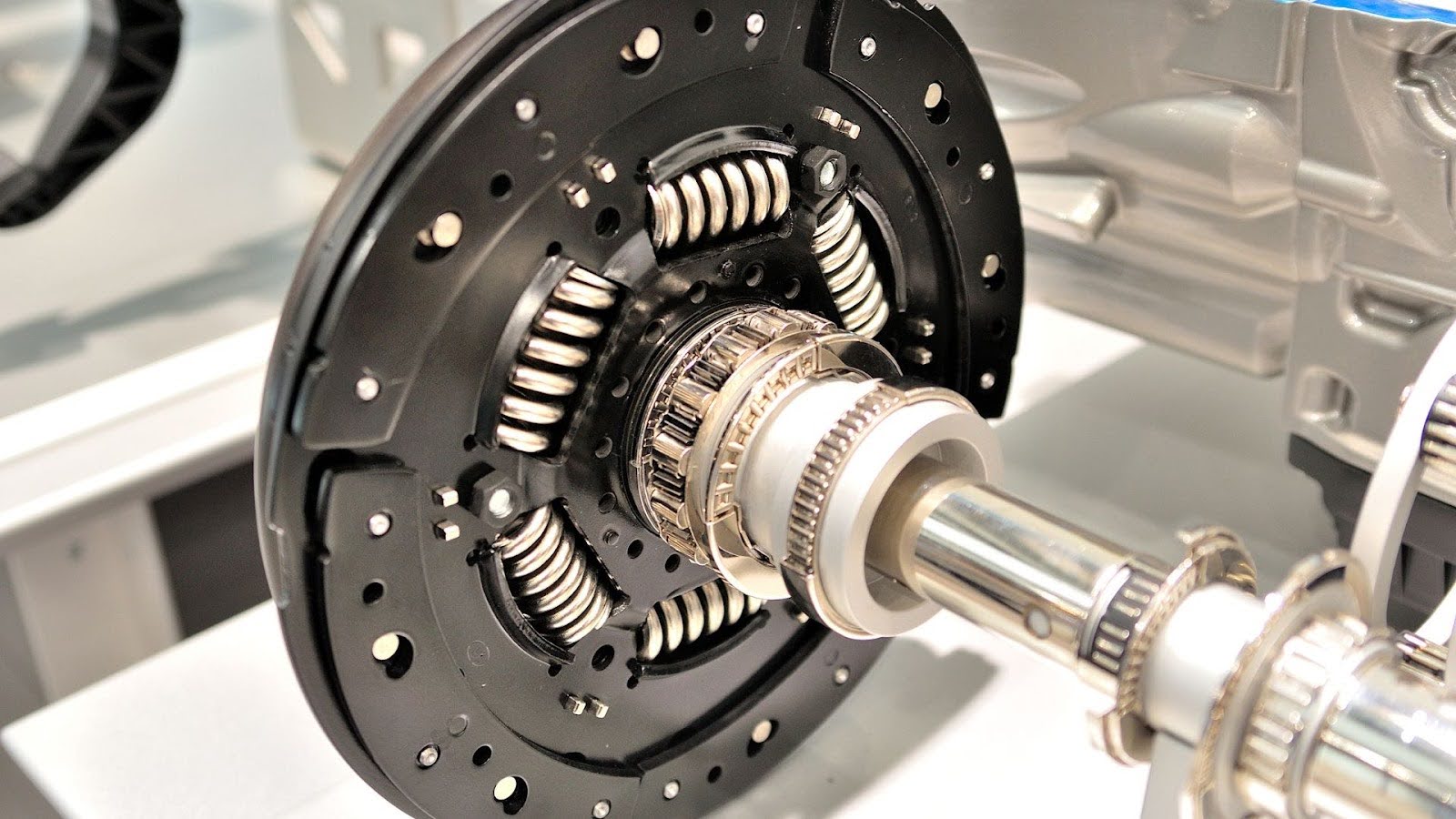

Landing Gear: Components of landing gear systems are cadmium plated to endure the significant wear and tear they experience during take-off, flight, and landing.

Engine Components: Critical engine parts are coated with cadmium to resist high-temperature corrosion and to facilitate heat dissipation.

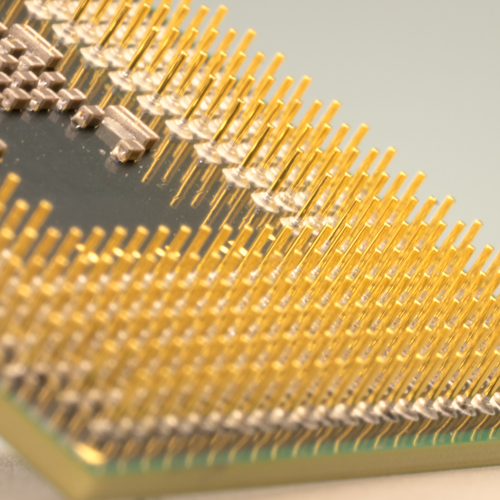

Avionics: Many electronic and precision instruments in avionics require cadmium plating for its excellent electrical conductivity and corrosion resistance.

Actuation Systems: Hydraulic actuators and related parts benefit from cadmium plating, which provides durable surfaces that can operate reliably in demanding conditions.

Take your aerospace and defense components to the next level with Valence Surface Tech’s Cadmium Plating Services, designed to meet the most rigorous industry applications. From enhancing aircraft fasteners to reinforcing landing gear, our plating services ensure unbeatable performance and reliability.

Benefits Of Cadmium Plating

Cadmium plating is essential in aerospace and defense for its role in improving component longevity and functionality under extreme conditions.2 Here are the top five applications of cadmium plating in these fields:

Enhanced Corrosion Resistance

Cadmium plating acts as a sacrificial barrier, corroding before the base material does, which significantly delays the onset of rust and corrosion on metal parts. This protective feature is particularly beneficial in environments with high humidity or exposure to corrosive substances, ensuring the longevity and reliability of critical components.

Superior Adhesion Properties

The surface created by cadmium plating is ideal for the adherence of coatings, such as paints and primers, which provides an additional layer of protection and can be used to improve aesthetics. This adhesion capability is key for aerospace components that require specific finishes to withstand operational stresses and to maintain a professional appearance.

Great Conductivity

Cadmium’s excellent electrical conductivity makes it a favored choice for plating aerospace and defense electrical connectors and components, ensuring uninterrupted electrical performance. This property is crucial for maintaining the integrity of electrical systems, especially in applications where any failure could be catastrophic.

Good Lubricity

The cadmium layer reduces surface friction, which helps to prevent the seizing and wear of components that are in constant motion or under high tension, thereby extending the service life of moving parts. This quality is especially valued in high-friction, dynamic environments where maintaining smooth operation of mechanisms is essential.

Reliable Performance In Extreme Conditions

Cadmium plated parts exhibit consistent performance across a diverse range of temperatures, from the intense cold of high-altitude flight to the high heat of engine components. This versatility ensures that aerospace and defense hardware maintain peak operation despite the challenging conditions they are routinely subjected to.

Environmental And Safety Considerations

As a toxic metal, cadmium requires rigorous control measures to limit exposure and mitigate potential hazards.3 Here are the top three environmental and safety considerations for cadmium plating:

Pollution Control

Implementing comprehensive wastewater treatment systems and air filtration technologies is essential to prevent the release of cadmium into the environment during the plating process.

Worker Safety

Strict adherence to safety protocols, including the use of personal protective equipment (PPE), proper ventilation, and regular health monitoring ensures the wellbeing of technicians and operators handling cadmium.

Regulatory Compliance

Compliance with local, national, and international regulations is crucial to operating a cadmium plating facility responsibly, including following guidelines for disposal, transport, and storage of cadmium and cadmium-containing materials.

Valence Surface Technologies Edge

Valence Surface Technologies emerges as an industry leader in cadmium plating, with a unique approach to surface technology solutions.4

Unparalleled Expertise

With a team of adept professionals, each a master in their respective field, Valence Surface Technologies ensures that every project we undertake is underpinned by expertise that is second to none. We pride ourselves on our ability to confront and conquer the complex challenges that accompany specialized metal finishing processes.

State-Of-The-Art Facilities

Our facilities are not just structures; they are the embodiment of our relentless drive for quality and efficiency. Equipped with the latest in metal finishing technologies, we are poised to handle the most demanding and intricate projects the industry presents. Our rigorous operational protocols, coupled with our flexible processing lines, are capable of accommodating a wide variety of customer needs while maintaining peak productivity and reliability.

The Valence Promise: Quality And Reliability

At the core of Valence’s offerings lies an unwavering pledge to quality and reliability in every project undertaken.

Adherence To Quality Standards

Our cadmium plating services are a paragon of precision engineering, aligning seamlessly with industry protocols and surpassing the stringent parameters set by governing bodies. This relentless pursuit of quality is deeply ingrained in our corporate ethos, reverberating through every layer of our operation—from the intricate calibration of our equipment to the meticulous training of our specialists.

On-Time Delivery

Our operational acumen is defined by a synergy of rapid response and rigor, ensuring that every project reaches its destination within the predetermined windows of time that our clients depend upon. This steadfast reliability in delivery is the hallmark of our service pledge, fostering resilient partnerships built on the bedrock of trust and efficiency.

The Future of Cadmium Plating

Cadmium plating remains an essential process in the evolution of aerospace technology, with continuous innovations ensuring it stays relevant and effective.5 At the forefront of these advancements, companies such as Valence Surface Tech are dedicated to honing their cadmium plating services, thereby enhancing the quality and efficiency of their offerings.

As the aerospace industry undergoes changes, these companies are adapting their cadmium plating techniques to align with emerging needs and future challenges, ensuring that they remain indispensable partners in the industry’s progress.

Final Thoughts On Cadmium Plating

Cadmium plating plays a pivotal role in advancing aerospace and defense industries by providing unmatched corrosion resistance, adhesion, and durability to components critical to these fields. Through meticulous procedural control and state-of-the art technology, companies like Valence Surface Tech have established themselves as leaders, continually enhancing the quality and applicability of cadmium plating services.

As we look to the future, the dedication to innovation, adherence to stringent environmental and safety measures, and commitment to surpassing industry standards solidify the indispensable nature of cadmium plating in these ever-evolving, high-stakes sectors.

Elevate your aerospace parts to new heights with Valence’s advanced Cadmium Plating Services. Don’t wait to unlock the full potential of your project—start plating today and experience the Valence difference. Request your quote here!

Frequently Asked Questions About Cadmium Plating

What is cadmium plating?

Cadmium plating is a process of applying a thin layer of cadmium to a metal substrate to protect it from corrosion. Cadmium is a soft, silvery-white metal that is highly resistant to corrosion.

How is cadmium plating done?

Cadmium plating is done by immersing a metal object in a solution of cadmium ions and then applying an electric current. The electric current causes the cadmium ions to deposit onto the metal surface.

What are the benefits of cadmium plating?

Cadmium plating offers enhanced corrosion resistance, superior adhesion properties, great conductivity, good lubricity, and reliable performance in extreme conditions.

What are the applications of cadmium plating?

Cadmium plating is used to protect metal parts in various applications including aerospace, automotive, industrial, and electronics.

What are the environmental and safety considerations for cadmium plating?

Cadmium is a toxic metal, so cadmium plating requires proper ventilation, personal protective equipment (PPE), wastewater treatment, and proper disposal of cadmium waste to protect workers and the environment.

What are the alternatives to cadmium plating?

Alternatives to cadmium plating include zinc plating, nickel plating, electroless nickel plating, chrome plating, and anodizing.

What is the future of cadmium plating?

Cadmium plating is a mature technology, but it is still used in a number of applications because of its unique properties. However, there is growing concern about the environmental and health risks of cadmium, so there is a trend towards using cadmium-free alternatives.

What are the advantages of using Valence Surface Tech for cadmium plating?

Valence Surface Tech offers unparalleled expertise, state-of-the-art facilities, commitment to quality and reliability, and on-time delivery for cadmium plating services.

What is Valence Surface Tech’s approach to sustainability?

Valence Surface Tech is committed to sustainability by reducing cadmium consumption, recycling cadmium-containing waste, and developing cadmium-free alternatives.

What are the key challenges and opportunities for Valence Surface Tech in the future?

The key challenges for Valence Surface Tech in the future are growing demand for cadmium-free alternatives, increasing cost of cadmium, and stricter environmental regulations, while the key opportunities are new technologies, new market expansion, and reputation strengthening.

Sources:

- Cadmium Plating: A Protective Coating for Aerospace and Defense Applications by Valence Surface Tech (2023)

- “Cadmium Plating: Benefits, Applications, and Considerations” by The American Society of Corrosion Engineers (NACE) (2022)

- “Cadmium Plating: A Sustainable Solution for Aerospace and Defense” by Metal Finishing Magazine (2021)

- “Cadmium Plating: Addressing Environmental and Safety Concerns” by The Environmental Protection Agency (EPA) (2020)

- “The Future of Cadmium Plating in Aerospace and Defense” by The Aerospace Industries Association (AIA) (2019)

- American Galvanizers Association. (2023). Cadmium Plating. Retrieved from https://galvanizeit.org/hot-dip-galvanizing

- National Institute for Occupational Safety and Health. (2023). Cadmium Plating. Retrieved from https://www.cdc.gov/niosh/topics/cadmium/default.html

- Metal Finishing Magazine. (2021). Cadmium Plating: A Sustainable Solution for Aerospace and Defense. Retrieved from https://techmetals.com/defense/

- The Environmental Protection Agency. (2020). Cadmium Plating: Addressing Environmental and Safety Concerns. Retrieved from https://www.army.mil/article/175722/precautions_necessary_in_cadmium_areas

- The Aerospace Industries Association. (2019). The Future of Cadmium Plating in Aerospace and Defense. Retrieved from https://www.newmethodplating.com/blog/aerospace-industry-needs-cadmium-plating/

- Valence Surface Tech. (2023). Cadmium Plating: A Protective Coating for Aerospace and Defense Applications. Retrieved from https://www.valencesurfacetech.com/

- The American Society of Corrosion Engineers. (2022). Cadmium Plating: Benefits, Applications, and Considerations. Retrieved from https://www.valencesurfacetech.com/the-news/cadmium-plating/

- Metal Finishing Magazine. (2022). Valence Surface Tech: Advancing Cadmium Plating for Aerospace. Retrieved from https://www.valencesurfacetech.com/

- Valence Surface Tech. (2023). Valence Surface Tech’s Commitment to Sustainability. Retrieved from https://www.valencesurfacetech.com/

- Aerospace Industries Association. (2023). Valence Surface Tech Leads the Way in Cadmium Plating Innovation. Retrieved from https://www.valencesurfacetech.com/the-story/leadership/

Plating Services

Cadmium Plating

Cadmium plating is a tough and versatile coating. The soft, attractive coating provides a favorable bonding surface for adhesions. It is also the preferred plating for salt-water environments due to its resistance to mold and bacteria.

Chrome Plating

Chromium plating is effective at providing excellent hardness and lubricity, reducing friction, minimizing wear, and preventing galling. In environments with corrosion or abrasion, chrome plating can withstand negative consequences on wear and tear.

Gold Plating

Gold plating advantages include good corrosion resistance, good solderability, and, when alloyed with cobalt, it has very good wear resistance. Gold is commonly used in electrical switch contacts, connector pins and barrels, and other applications where intermittent electrical contact occurs. It is also used as a radiation shield, in infrared reflectors and satellite electronic housings. Valence also offers immersion gold plating.

Manganese Phosphate

Manganese phosphate coating is a conversion coating, the formulation of which contains a manganese salt, phosphoric acid and an accelerator. This process is done under high temperature, and produces a surface that has good corrosion and wear resistance. Manganese phosphate coatings can retain oil and other lubricants.

Nickel Sulfamate

Nickel sulfamate is a plating process that provides a highly ductile plating surface with low internal stress. The versatility of the coating resists high temperatures, maintains high tensile strength, and provides ductility and elongation.

Ti-Cad Plating

Ti-Cad or titanium cadmium plating is a titanium cadmium combination plating that provides corrosion resistance on high strength steel applications. It significantly reduces the negative consequences of hydrogen embrittlement.

Tin Plating

Tin plating is used extensively to protect both ferrous and nonferrous surfaces. Tin is also widely used in the electronics industry because of its ability to protect the base metal from oxidation and corrosion. Depending on the base material, tin is used as a metal plating to maintain or impart solderability. Valence also offers tin lead plating.

Valence performs all of these services to the highest degree of care, with approvals for most prime, aerospace, and military specifications. Our products and services significantly enhance safety, long-term use, and consistency in the aerospace industry. View our specs here.

Plating Tank Sizes

| Valence Wichita | L | Valence Garden Grove | L |

|---|---|---|---|

| Cadmium Types I, II, III | 4′ | Copper Plate | 2′ |

| Electroless Ni-Mid | 4′ | Electroless Ni- Hi Phos | 6′ |

| Electroless Ni-Hi Phos | 2.5′ | Electroless Ni- Low phos | 3′ |

| Hard Chrome | 14′ | Electroless Ni- Mid phos | 7.5′ |

| Hard Chrome | 7′ | Gold Immersion | 2′ |

| TiCad | 4′ | Gold Plate – Grade A Type lll | 2′ |

| Gold Plate – Grade C, Type II | 3.5′ | ||

| Gold Plate – Grade D, Type I, Type II | 1.5′ | ||

| Gold Strike | 3′ | ||

| Nickel Plate – Bright /Semi Bright | 4.5′ | ||

| Nickel Plate – Semi Bright | 4.5′ | ||

| Nickel Sulfamate | 4.5′ | ||

| Silver Plate – Semi Bright | 3.5′ | ||

| Sliver Plate – Matte | 5′ | ||

| Tin Plate | 4.5′ | ||

| Tin/Lead Plate (60/40) | 3′ | ||

| Tin/Lead Plate (90/10-95/5) | 2.5′ |

Plating News

Chrome Coating: A Necessary Investment for Aerospace Components

Chrome coating is not just a crucial investment, it's a necessity for aerospace components that are exposed to harsh conditions during flight. It offers a range of benefits, including enhanced durability, corrosion resistance, and improved performance. If you want to...

Gold Plating: The Best Way To Protect Aerospace Components From Tarnish

In the aerospace industry, the significance of gold plating cannot be overstated. This process plays a crucial role in safeguarding vital components against the detrimental effects of tarnish and corrosion. Unlike alternative plating techniques, gold plating stands...

Understanding The Different Types Of Gold Plating

Gold plating serves as a renowned metal finishing strategy that incorporates a delicate gold layer onto a metal object's surface. This gold veneer delivers an array of advantages such as augmented corrosion resistance, superior electrical conductivity, enhanced heat...

Choosing The Right Finish: Anodizing Vs. Powder Coating

Choosing the appropriate finish for a project, such as anodizing or powder coating, can present quite a challenge. Both of these finishes have distinct advantages and considerations, making it crucial to fully grasp their unique characteristics to guide your...