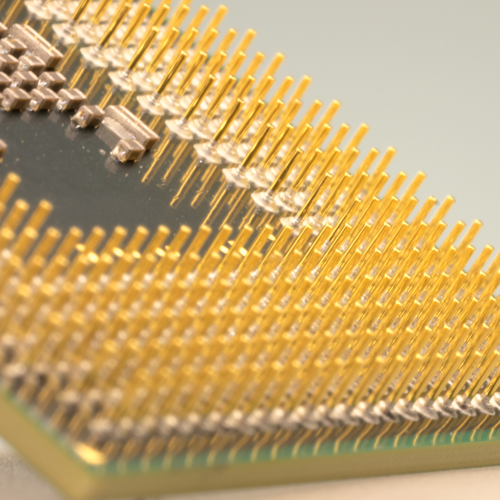

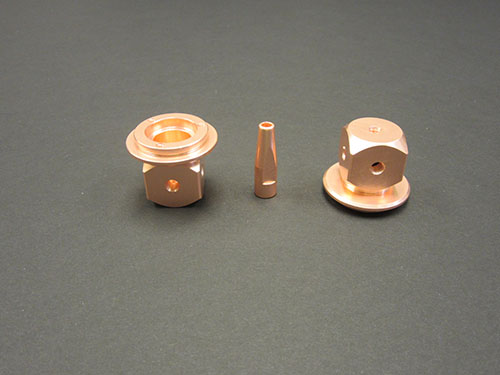

Copper Plating

Copper electroplating at Valence is applied as an undercoat or strike between the substrate and final deposit. We offer a tarnish inhibitor (anti-tarnish) application for those applications that require copper as a final finish.

Our plating methods include Barrel plating, Rack plating, and Brush plating. Barrel and Rack plating are immersion copper plating methods; brush plating is applied outside the tank

Valence Surface Technologies can

Copper plating thickness measuring is performed using the X-Ray Fluorescence method in accordance with ASTM B 568. Instruments used to determine copper plating thickness are Fischercope X-Ray units, accomplishing a margin of error less than 1% using certified thickness foil standards.

Custom masking is available for plating selective areas and applying multiple processes to one part.

Request a quote on copper plating for your application, or contact us to learn more.

Copper Plating Process