Electroless Nickel Plating Services

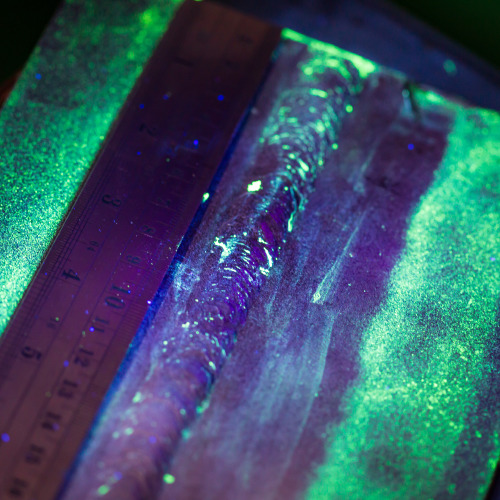

Electroless nickel plating is a chemical process that deposits a layer of nickel-phosphorus or nickel-boron alloy on the surface of a metal or plastic. This layer provides various beneficial properties, including corrosion resistance, hardness, and even wear resistance to the substrate material. Valence Surface Technologies offers specialized electroless nickel plating services tailored to meet the rigorous demands of industries where precision and durability are paramount.

Experience the benefits of choosing the only completely integrated solution for aerospace surface finishing. Partner with Valence Surface Technologies and elevate the performance and reliability of your aerospace components.

What Is Electroless Nickel Plating?

Electroless nickel plating is a deposition process that chemically applies a nickel-phosphorus or nickel-boron alloy layer to a substrate, using an autocatalytic reaction. It is characterized by the ability to coat parts evenly without the need for an external power source, unlike traditional electroplating methods.

The resulting finish has excellent properties, including consistent thickness over complex geometries and superior adhesion to the base material. By controlling the phosphorus content in the plating bath, we can tailor the properties of the deposited layer according to the specific needs of the component. Valence Surface Tech leverages this process to provide versatile and durable finishes that serve a vast range of industrial applications.

Applications Of Electroless Nickel Plating

This method is widely used due to its ability to coat parts uniformly, regardless of their shape. Here are some key applications of electroless nickel plating:

Aerospace And Defense

In the aerospace and defense industries, having components that can endure extreme environments and wear is pivotal. Electroless nickel plating is a preferred surface treatment in these sectors due to its excellent corrosion resistance and ability to maintain its properties under high stress.

Valence excels in servicing these crucial industries by implementing selective plating and precision masking techniques, especially for the high tolerance demands of satellite and UAV components. With our surface treatment, components exhibit improved longevity and reliability, which is crucial for both safety and the success of critical missions. Our advanced capability in electroless nickel plating ensures the highest level of performance and protection for aerospace and defense applications.

Automotive Industry

The automotive industry continuously seeks solutions that enhance the lifespan and efficiency of vehicle components. Electroless nickel plating is integral for parts exposed to high temperatures and frictional forces, such as fuel systems, engines, and braking mechanisms.

The consistent and protective coating we provide at Valence Surface Technologies extends the durability of these automotive parts, helps prevent premature failure, and ensures optimal vehicle performance. The ability of electroless nickel plating to resist wear and corrosion also contributes to overall vehicle safety. By delivering superior plating services, we help automotive manufacturers maintain the highest standards in component quality and functionality.

General Industry

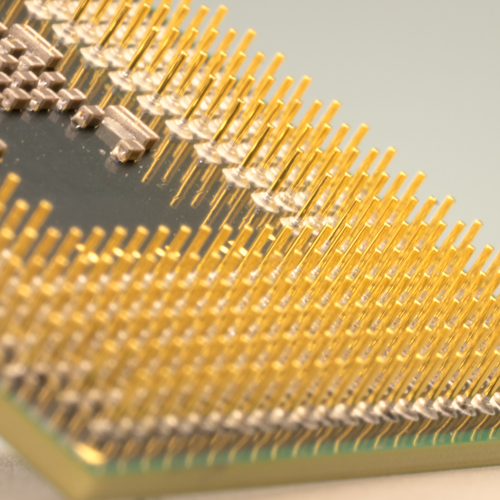

Numerous industrial sectors rely on parts that must withstand corrosive environments and repetitive mechanical stress. Electroless nickel plating is widely used across various industries, including oil and gas, maritime, and electronics, due to its ability to enhance component longevity and reliability.

At Valence Surface Technologies, we recognize the diverse needs of these industries and provide electroless nickel plating that resists both chemical deterioration and physical wear. Our services extend the working life of tools, molds, dies, and other crucial machinery components. By improving resistance to operational challenges, we help industries minimize downtime and maintenance costs.

Valence Surface Tech’s Electroless Nickel Plating Expertise

Valence Surface Technologies demonstrates considerable expertise in electroless nickel plating, offering a variety of specialized coatings to meet diverse industry needs. This method provides several advantages:

Custom Solutions

Understanding the unique requirements of each project is central to Valence’s approach to electroless nickel plating. We collaborate closely with our clients to configure custom plating solutions that meet their specific needs for performance, wear resistance, and corrosion protection. Our high-quality finishing processes are lined with the precision necessary to treat each component’s nuanced details.

Quality And Precision

Valence Surface Technologies’ commitment to delivering the highest quality in electroless nickel plating is grounded in our advanced technical capabilities. We employ state-of-the-art equipment and finely tuned processes to ensure the accurate application of plating, adhering to even the most exacting industrial specifications.

Our skilled technicians focus on precision, capitalizing on the inherent benefits of electroless plating to maintain uniform thickness and comprehensively coat even the most intricate of parts.

Certification And Standards

Adhering to stringent industry regulations and maintaining an array of certifications is a cornerstone of the services we provide. These certifications are not merely accolades but represent our pledge to uphold the highest possible standards in electroless nickel plating services.

They manifest our commitment to continuous improvement, consistent quality, and satisfied customers. Our processes are vigorously audited, ensuring their alignment with critical aerospace, automotive, and general industry requirements.

Maintenance And Care For Electroless Nickel-Plated Surfaces

Proper maintenance and care are essential to preserve the integrity and functionality of electroless nickel-plated surfaces. Here are some guidelines:

Best Practices For Prolonging The Life Of Nickel-Plated Parts

Periodic maintenance and proper care are vital to maximizing the lifespan of electroless nickel-plated parts. Regular cleaning to remove dirt, oils, and chemicals is recommended to maintain the integrity of the coating. The use of non-abrasive cleaners and soft cloths helps to prevent scratching the surface. In addition, it is crucial to follow any specific maintenance guidelines provided by the plating service, as particular environments or applications may require unique care practices.

Identifying And Preventing Common Issues In Nickel-Plated Components

Ensuring the longevity of electroless nickel-plated components involves vigilance in identifying common issues such as staining, dullness, or pitting. These problems may arise due to environmental exposure, improper cleaning, or material incompatibilities.

To prevent such issues, it’s important to implement appropriate handling and storage, minimize exposure to corrosive substances, and ensure that the plating process has been executed to the highest standards. If issues do occur, consulting with the plating provider can offer solutions to rectify the problem and avoid recurrence.

Benefits Of Electroless Nickel Plating

Electroless nickel plating offers several benefits, making it a popular choice for various industrial applications:

Enhanced corrosion resistance: Electroless nickel plating provides excellent protection against a wide range of corrosive environments, including acids, alkalis, salts, and organic solvents. This makes it an ideal choice for components that are exposed to harsh conditions, such as those used in the automotive, aerospace, and marine industries.

Improved wear and abrasion resistance: Electroless nickel plating is extremely hard and durable, making it resistant to wear and abrasion. This property is particularly beneficial for components that are subjected to frequent friction or sliding contact, such as gears, bearings, and molds.

Uniform coating thickness: Electroless nickel plating produces a uniform coating thickness, even on complex geometries. This ensures that all parts of the substrate are evenly protected from corrosion and wear.

High hardness: Electroless nickel plating can be heat-treated to achieve a very high hardness. This makes it an excellent choice for applications that require extreme wear resistance, such as cutting tools and molds.

Environmentally friendly: Electroless nickel plating is a relatively environmentally friendly process. It does not use toxic chemicals or generate hazardous waste.

Comparison Of Electroless Nickel Plating With Other Plating Methods

Electroless nickel plating offers distinct advantages over other plating methods, such as traditional electroplating or chrome plating. Here’s a comparison:

Electroless vs. Electrolytic Nickel Plating

Electroless and electrolytic nickel plating are both popular methods for applying nickel coatings, but they differ significantly in application and results. Electrolytic plating requires an electric current, which can lead to uneven coating thickness, especially in complex geometries.

In contrast, electroless plating achieves a uniform thickness across the entire surface, including internal cavities and threads, which is pivotal for consistent part performance. Additionally, electroless nickel plating can be precisely tailored to deliver specific levels of phosphorus content, offering a range of hardness and corrosion resistance that electrolytic plating may not match.

The Distinction Between Electroless Plating And Chrome Plating

Chrome plating and electroless nickel plating cater to different aesthetic and functional needs. Chrome plating is well-known for its bright, reflective finish and is often used for decorative purposes. However, it lacks the uniformity and specific property customization that electroless nickel plating provides. Electroless nickel, on the other hand, excels in engineering applications due to its superior wear and corrosion resistance, offering a more versatile solution for industrial uses.

Final Thoughts On Electroless Nickel Plating

The choice of a service provider for electroless nickel plating requires consideration of both technical acumen and industry insight. Valence Surface Technologies brings together unparalleled expertise, a culture of quality, and a proven history of fulfilling advanced plating service needs for an array of critical applications.

Our one-stop-shop solution appeals to businesses seeking hassle-free, reliable, and technologically advanced electroless nickel plating services. We take pride in our ability to make business processes smoother and more productive for our clients, becoming an integral part of their success story. Choose Valence Surface Technologies, and experience the peace of mind that comes from partnering with a leader in surface technology and finishing services.

Ready to embark on an exploration of the endless opportunities and market potential in this ever-evolving field? Join us as we unravel the fascinating world of aerospace finishing and why Valence Surface Tech stands as your unrivaled partner in excellence.

Frequently Asked Questions About Electroless Nickel Plating

What is electroless nickel plating?

Electroless nickel plating is an autocatalytic chemical process that deposits a thin layer of nickel-phosphorus alloy on a substrate. The process does not require an external electrical current, which is why it is called “electroless.” The nickel-phosphorus alloy coating is hard, wear-resistant, and corrosion-resistant, making it a valuable finish for a variety of applications.

How does electroless nickel plating work?

The electroless nickel plating process involves immersing the substrate in a plating bath containing nickel ions, a reducing agent, and a stabilizer. The reducing agent causes the nickel ions to be reduced to metallic nickel, which deposits on the substrate. The stabilizer prevents the nickel from depositing on the walls of the plating tank.

What are the benefits of electroless nickel plating?

Electroless nickel plating offers a number of benefits over other plating processes, including:

- Uniform coating thickness, even on complex shapes

- Hard, wear-resistant, and corrosion-resistant coating

- No electrical current required

- Can be plated on a variety of substrates, including metals, plastics, and ceramics

What are the applications of electroless nickel plating?

Electroless nickel plating is used in a variety of applications, including:

- Automotive components

- Aerospace components

- Electronics components

- Medical devices

- Printing circuit boards

What are the different types of electroless nickel plating?

There are two main types of electroless nickel plating:

- Matte electroless nickel plating: This type of plating produces a matte or non-reflective finish. It is often used for applications where a smooth, wear-resistant surface is required.

- Bright electroless nickel plating: This type of plating produces a bright, reflective finish. It is often used for decorative applications.

How much does electroless nickel plating cost?

The cost of electroless nickel plating depends on a number of factors, including the size and complexity of the part, the thickness of the coating, and the type of plating required. In general, electroless nickel plating is a more expensive plating process than electroplating.

What is the process of electroless nickel plating?

The electroless nickel plating process typically involves the following steps:

- Cleaning: The substrate is cleaned to remove any dirt, grease, or other contaminants.

- Activation: The substrate is activated to make it receptive to the plating process. This may involve immersing the substrate in an acidic solution.

- Plating: The substrate is immersed in a plating bath containing nickel ions, a reducing agent, and a stabilizer. The nickel ions are reduced to metallic nickel, which deposits on the substrate.

- Rinsing: The substrate is rinsed to remove any excess plating solution.

- Drying: The substrate is dried.

How thick are electroless nickel coatings?

The thickness of electroless nickel coatings can range from a few micrometers to several hundred micrometers

What is the electroless nickel plating bath composition?

The electroless nickel plating bath composition typically includes the following:

- Nickel ions

- Reducing agent (such as sodium hypophosphite)

- Stabilizer (such as citric acid)

- Water

What are the operating parameters for electroless nickel plating?

The operating parameters for electroless nickel plating will vary depending on the specific application. However, the typical operating parameters include:

- Temperature: 85-95°F

- pH: 8-9

- Plating time: 30-60 minutes

Sources:

- American Society for Testing and Materials (ASTM). (2019). Standard practice for electroless plating of nickel and nickel-cobalt (ASTM B432-19). In ASTM International Standards. https://www.techstreet.com/standards/astm-b432-19?product_id=2043152

- Blocher, J. D., & Enchelmaier, J. F. (2023). Electroless plating: Fundamentals and applications (3rd ed.). Elsevier. https://books.google.com/books/about/Electroless_Plating.html?id=2nmPKm6jEooC

- Burden, F. P., & Lawless, D. V. (1995). Surface treatment and finishing (4th ed.). Marcel Dekker. https://www.amazon.com/Surface-Science-Foundations-Catalysis-Nanoscience-ebook/dp/B082359HZX

- Davis, J. R. (1995). Surface engineering (2nd ed.). ASM International. https://www.sanfoundry.com/best-reference-books-surface-engineering/

- Kay, A. E. (Ed.). (2023). Proceedings of the 58th International Electroless Nickel and Chemical Plating Conference. AESF. https://onlinelibrary.wiley.com/doi/abs/10.1002/aenm.202204075

- American Society for Testing and Materials (ASTM). (2022). Standard practice for electroless nickel plating of autocatalytic nickel-phosphorus (ASTM B650-22). In ASTM International Standards. https://www.enstechnology.com/mil-spec/mil-c-26074-e

- Napier, D. H., Dumas, P., & Etchells, C. M. (2020). Electroless plating of metals and alloys (5th ed.). CRC Press. https://www.amazon.com/Electroless-Plating-Glenn-Mallory/dp/0815512775

Plating Services

Cadmium Plating

Cadmium plating is a tough and versatile coating. The soft, attractive coating provides a favorable bonding surface for adhesions. It is also the preferred plating for salt-water environments due to its resistance to mold and bacteria.

Chrome Plating

Chromium plating is effective at providing excellent hardness and lubricity, reducing friction, minimizing wear, and preventing galling. In environments with corrosion or abrasion, chrome plating can withstand negative consequences on wear and tear.

Gold Plating

Gold plating advantages include good corrosion resistance, good solderability, and, when alloyed with cobalt, it has very good wear resistance. Gold is commonly used in electrical switch contacts, connector pins and barrels, and other applications where intermittent electrical contact occurs. It is also used as a radiation shield, in infrared reflectors and satellite electronic housings. Valence also offers immersion gold plating.

Manganese Phosphate

Manganese phosphate coating is a conversion coating, the formulation of which contains a manganese salt, phosphoric acid and an accelerator. This process is done under high temperature, and produces a surface that has good corrosion and wear resistance. Manganese phosphate coatings can retain oil and other lubricants.

Nickel Sulfamate

Nickel sulfamate is a plating process that provides a highly ductile plating surface with low internal stress. The versatility of the coating resists high temperatures, maintains high tensile strength, and provides ductility and elongation.

Ti-Cad Plating

Ti-Cad or titanium cadmium plating is a titanium cadmium combination plating that provides corrosion resistance on high strength steel applications. It significantly reduces the negative consequences of hydrogen embrittlement.

Tin Plating

Tin plating is used extensively to protect both ferrous and nonferrous surfaces. Tin is also widely used in the electronics industry because of its ability to protect the base metal from oxidation and corrosion. Depending on the base material, tin is used as a metal plating to maintain or impart solderability. Valence also offers tin lead plating.

Valence performs all of these services to the highest degree of care, with approvals for most prime, aerospace, and military specifications. Our products and services significantly enhance safety, long-term use, and consistency in the aerospace industry. View our specs here.

Plating Tank Sizes

| Valence Wichita | L | Valence Garden Grove | L |

|---|---|---|---|

| Cadmium Types I, II, III | 4′ | Copper Plate | 2′ |

| Electroless Ni-Mid | 4′ | Electroless Ni- Hi Phos | 6′ |

| Electroless Ni-Hi Phos | 2.5′ | Electroless Ni- Low phos | 3′ |

| Hard Chrome | 14′ | Electroless Ni- Mid phos | 7.5′ |

| Hard Chrome | 7′ | Gold Immersion | 2′ |

| TiCad | 4′ | Gold Plate – Grade A Type lll | 2′ |

| Gold Plate – Grade C, Type II | 3.5′ | ||

| Gold Plate – Grade D, Type I, Type II | 1.5′ | ||

| Gold Strike | 3′ | ||

| Nickel Plate – Bright /Semi Bright | 4.5′ | ||

| Nickel Plate – Semi Bright | 4.5′ | ||

| Nickel Sulfamate | 4.5′ | ||

| Silver Plate – Semi Bright | 3.5′ | ||

| Sliver Plate – Matte | 5′ | ||

| Tin Plate | 4.5′ | ||

| Tin/Lead Plate (60/40) | 3′ | ||

| Tin/Lead Plate (90/10-95/5) | 2.5′ |

Plating News

Chrome Coating: A Necessary Investment for Aerospace Components

Chrome coating is not just a crucial investment, it's a necessity for aerospace components that are exposed to harsh conditions during flight. It offers a range of benefits, including enhanced durability, corrosion resistance, and improved performance. If you want to...

Gold Plating: The Best Way To Protect Aerospace Components From Tarnish

In the aerospace industry, the significance of gold plating cannot be overstated. This process plays a crucial role in safeguarding vital components against the detrimental effects of tarnish and corrosion. Unlike alternative plating techniques, gold plating stands...

Understanding The Different Types Of Gold Plating

Gold plating serves as a renowned metal finishing strategy that incorporates a delicate gold layer onto a metal object's surface. This gold veneer delivers an array of advantages such as augmented corrosion resistance, superior electrical conductivity, enhanced heat...

Choosing The Right Finish: Anodizing Vs. Powder Coating

Choosing the appropriate finish for a project, such as anodizing or powder coating, can present quite a challenge. Both of these finishes have distinct advantages and considerations, making it crucial to fully grasp their unique characteristics to guide your...