Peen Forming: Precision Engineering For Aerospace Excellence

What Is Peen Forming?

Peen forming is a metalworking process employed to shape, straighten, and strengthen materials by hammering them with high-velocity shots. This precise method induces favorable compressive stresses on the surface, considerably improving the material’s resistance to fatigue and enhancing its overall durability. Peen forming is widely used in the aerospace industry and is essential for components that need to meet strict standards and have long service lives.

The Process Of Peen Forming: A Step-By-Step Guide

Preparation Of The Workpiece

The initial step in peen forming is the meticulous preparation of the metal component. It involves cleaning the surface to remove any rust, scale, or contaminants that might impede the peening process. This phase is crucial because impurities can cause uneven peening and may risk the final quality of the workpiece. Furthermore, a thorough inspection of the workpiece for any existing defects is vital to achieve optimal outcomes from the peening process.

Setting Up The Equipment

The second step involves the precise setup of the peen-forming equipment. This process involves adjusting the shot blasting machine to regulate the size, type, and speed of the shot, all of which are essential elements in determining the success of the procedure. The selection of shot material, whether it be steel, glass, or ceramic, depends on the intended result and the characteristics of the metal undergoing treatment. Correctly setting up the equipment is key to getting even coverage and the right surface texture on the workpiece.

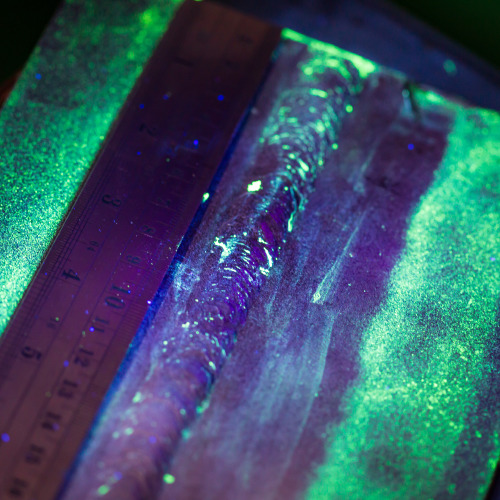

Executing The Peen Forming Process

During this phase, the workpiece is subject to a controlled shot stream. This process creates compressive stress on the surface, resulting in the intended bending or hardening of the metal. The technician carefully oversees the process to guarantee uniform shot distribution and maintain the proper intensity, which is crucial for obtaining the desired surface properties. Adjustments are made to ensure uniform treatment across the workpiece’s entire surface.

Quality Control And Inspection

After the peening is complete, the workpiece undergoes a rigorous inspection process. This step is vital to confirm that the peening produced the desired effects, such as achieving the correct surface finish and structural integrity. Dimensional accuracy checks ensure that the workpiece conforms to the specified tolerances. Any deviations are addressed. If necessary, the piece may be subject to additional peening.

Post-Processing Treatments

The workpiece may undergo additional treatments to further enhance its properties. This could include heat treatment to relieve stresses induced by peening or applying protective coatings to improve corrosion resistance. These subsequent processing steps are adaptable to the unique needs of the project and are essential for optimizing the performance and lifespan of the final product.

Applications Of Peen Forming In Industry

Aerospace Industry

In the aerospace industry, peen forming plays a key role in shaping and reinforcing vital components like wings and fuselage panels. The process shapes and strengthens parts to handle stress, making it crucial for building and maintaining aircraft.

Automotive Manufacturing

The automotive industry benefits significantly from peen forming, especially in crafting body panels and structural components. This method makes sure parts are strong and durable, helping to keep vehicles safe and long-lasting.

Heavy Machinery And Construction

Peen forming is very important in making heavy machinery and construction equipment. Parts treated with peen forming show improved resistance to wear and tear and are stronger, which is important for machines that work in tough conditions.

Medical Device Manufacturing

Peen forming is used to refine the surface of surgical tools and implants. The process not only improves the longevity of these devices but also enhances their performance in medical procedures.

Energy Sector

Within the energy sector, particularly in wind and hydroelectric power, peen forming fortifies components exposed to extreme environmental conditions. This ensures their reliability and efficiency in energy generation.

The Valence Approach To Quality Peen Forming Services

At Valence, their dedication to quality is clear in every aspect of their peen-forming services.

Industry-Leading Expertise

At Valence, an experienced team is always prepared to guide peen forming services from start to finish, making sure every step meets the strict standards required by the aerospace industry. They use their extensive experience and deep knowledge to make sure each project gets the individual attention it deserves. This method guarantees the effective use of peen-forming techniques, producing components of exceptional quality and performance.

Groundbreaking Techniques

As leaders in the aerospace finishing industry, Valence uses the newest and most innovative peen forming technologies and methods to keep their services at the forefront. Valence’s involvement in research and development allows them to introduce advanced solutions, constantly improving peen-forming techniques to meet the changing demands of aerospace manufacturing. This progressive approach leads to noticeable enhancements in the quality and effectiveness of the components Valence produces.

Comprehensive Client Support

Valence offers comprehensive support covering all stages of the service chain, giving clients guidance and help from the initial phases to post-production follow-up. Valence maintains clear communication and a responsive client care method, ensuring their peen-forming services integrate smoothly into clients’ operations, enabling an effortless transition from processing to application.

Innovations In Peen Forming At Valence

Valence embodies forward-thinking by constantly incorporating the latest methods and technological innovations into its peen-forming processes. Valence’s commitment to innovation is evident not only in its adoption of new technologies but also in its development of unique techniques that enhance the effectiveness and efficiency of peen forming.

Valence’s dedication to expanding the limits of what is possible places them at the forefront in offering specialized services that meet the intricate requirements of contemporary aerospace projects. So what are you waiting for? Partner With Valence today!

Benefits Of Peen Forming For Aerospace Components

Peen forming offers numerous advantages that align closely with the objectives of aerospace manufacturing.

Enhanced Fatigue Resistance

One of the key benefits of peen forming is its ability to induce compressive stresses on the surfaces of components. This process reduces the start and spread of cracks, which is very important for the long life and safety of aerospace parts. Improving fatigue resistance is especially important for aerospace parts that go through a lot of cyclic loading during flight. This makes sure they work reliably for their entire service life.

Superior Stress Distribution

Peen forming provides a way to achieve better stress distribution across the surfaces of components. This even spread of stress helps reduce the risk of stress concentration, which often leads to material failure. Peen forming helps to keep the structure of components strong even under tough conditions by making sure stresses are spread out more evenly. This results in aircraft parts being more capable of handling different loads and pressures during flight, ensuring peak performance and safety.

Optimal Aerodynamic Properties

The accuracy of the peen-forming process directly affects how aerodynamic aerospace components are. Adjusting the surface properties can result in smoother profiles and less aerodynamic drag, leading to more efficient flight overall. This precise adjustment also improves fuel efficiency, which significantly impacts operational costs and the environment.

Long-Term Reliability And Partnership

More than just offering a service, a true partnership is about consistently delivering reliable results over and over. It involves backing the quality of the work provided and supporting the client’s success in the long term. By offering services designed for long-term performance and focusing on establishing enduring relationships, collaborating with a company committed to maintaining top-notch peen-forming services becomes a key part of a client’s continued success in the aerospace sector.

Final Thoughts On Peen Forming

Peen forming is more than a process. It’s a driving force for achieving excellence in the manufacturing of aerospace components. By leveraging the capabilities of peen forming and the expertise of Valence Surface Technologies, aerospace firms can confidently explore new levels of performance and innovation.

Frequently Asked Questions

Are there specific aerospace applications where peen forming is particularly beneficial?

Peen forming is crucial for components requiring exacting standards, high durability, and prolonged service lives, which is common in aerospace critical parts.

What role does material selection play in the success of peen forming for aerospace components?

Material choice significantly influences peen-forming outcomes, and Valence’s experts tailor media selection to match specific metals and applications.

How does peen forming impact the structural integrity of aerospace components in high-stakes environments like military and defense applications?

Peen forming ensures robustness, meeting and exceeding the rigorous standards demanded in military and defense applications.

Can Valence’s peen forming process be seamlessly integrated into existing aerospace manufacturing workflows?

Valence works closely with manufacturing teams to integrate peen forming efficiently, enhancing overall production without compromising quality.

What guarantees the quality of aerospace components formed through peen forming at Valence?

Stringent quality control measures and adherence to aerospace standards ensure each component meets the highest level of compliance.

How does peen forming contribute to optimal aerodynamic properties in aerospace components?

Precision shaping via peen forming allows for tighter tolerances, improving aerodynamics crucial for optimal in-flight performance.

Are there specific technologies or innovations Valence employs to further enhance the peen forming process?

Valence invests in smart technologies, custom machinery, and advanced media for shot peening, constantly innovating to meet evolving aerospace requirements.

What kind of precision can aerospace companies expect when utilizing Valence’s peen forming services?

Valence’s expertise ensures meticulous precision, allowing for tighter tolerances and improved performance in aerospace components.

In what ways does peen forming address the challenges faced by aerospace industries in terms of component strength and resilience?

Peen forming imparts unparalleled strength and resilience, vital for components operating under extreme conditions and high-altitude pressures.

Does peen forming affect the weight or overall efficiency of aerospace components?

Peen forming optimizes material strength without compromising weight, contributing to increased efficiency and durability.

Shot Peen and Blasting Services

Saturation Peen

Saturation peen refers peening the entire surface of a part, to enhance fatigue resistance. Based on our equipment capability, we can support large quantity orders, or individual parts with a large surface area.

Peen Forming

Peen forming is the process of using small steel shot to change the curvature of a part.

Abrasive Blast / Abrasive Clean

- Abrasive Blast / Abrasive Clean – Abrasive blasting and cleaning is used to smooth, or to roughen a surface.

- Aluminum Oxide – Aluminum oxide is a commonly used abrasive for blast finishing and surface preparation.

- Glass Bead Blasting – Glass bead blasting refers to circular glass shot that create a softer, brighter finish on surfaces.

- Plastic Media – Plastic media is a soft shot type that is the preferred and nondestructive way to strip coatings and paint from delicate parts, without compromising part integrity.

Shot Peen and Blast Sizes

| Valence Eastman | L | Valence Wichita | L | Valence Grove | L | Valence Los Angeles | L | Valence Seattle | L | Valence Everett | L | Valence Paramount | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Abrasive Blast | 5' | Abrasive Blast | 14' | Glass Bead | 10' | Abrasive Blast | 32' | Abrasive Blast | 4' | Abrasive Blast | 12' | Abrasive Blast | 40' |

| Part Mark | No Limit | Glass Bead | 5' | Part Mark | No limit | Glass Bead | 6' | Glass Bead | 3' | Glass Bead | 12' | Glass Bead | 50' |

| Shot Peen | 5' | Part Mark | No limit | Shot Peen | 3' | Plastic Media | 6' | Part Mark | No limit | Part Mark | No limit | Shot Peen | 50' |

| Shot Peen | 12 | Part Mark | No limit | Plastic Bead Blast | 2.5' | Shot Peen | 30' | Shot Peen Form | 40' | ||||

| Shot Peen | 6' |

Shot Peen and Blasting News

Valence Surface Technologies achieves Nadcap accreditation for a new shot peen plant in the Pacific Northwest

Seattle, Washington and The Woodlands, Texas -- Valence Surface Technologies (Valence), the world’s largest independent provider of metal processing and finishing services in the aerospace and defense industry, has received Nadcap accreditation for its new state of...