Nickel Plating

Nickel is a grey-white metal with a slight yellow tint. Nickel plate can have a matte non-reflective finish or a very bright reflective finish.

Nickel is one of the four ferromagnetic materials at room temperature and is a fairly active element. However, nickel deposits are slow to react in standard atmospheric environments due to the formations of a protective oxide surface providing excellent corrosion performance on most products

Sulfamate Nickel Plating

Valence Surface Technologies performs two types of Sulfamate Nickel plating: Matte Low-Stressed Sulfamate Nickel Plating, and Semi-Bright Sulfamate Nickel plating.

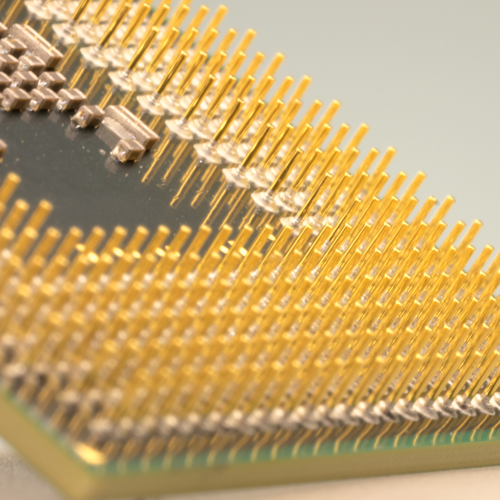

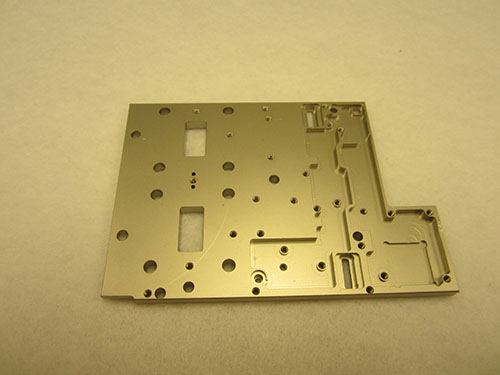

Matte Sulfamate Nickel plating produces a 99.9% pure deposit without any organic brighteners or levelers. The high purity of the deposit affords temperature resistance up to the 1400°C+ melting point of pure nickel. These deposits have a full matte appearance with a slight yellow or golden cast not known for decorative appeal. They also have extremely low deposit stress that can be in the compressive range. The low stress of sulfamate nickel plating yields nickel deposits with ductility, elongation, and machinability far superior to other nickel deposits.

Matte Sulfamate Nickel plating excels in joining applications including brazing, soldering, over molding, epoxy bonding, and welding. The high purity and lack of co-deposited organics improve the wetting of the nickel deposit when soldering and

Semi-Bright Sulfamate Nickel plate is used in places where a bright surface gives a decorative appearance. Semi-Bright Sulfamate is primarily used in areas where handling would discolor Matte Sulfamate nickel. Semi-Bright sulfamate nickel has excellent corrosion resistance and slightly lower solderability than matte sulfamate nickel. However, it is harder and has excellent corrosion resistance.

Valence (Garden Grove) has extensive experience in sulfamate nickel plating in uses extending from shuttle turbo-pumps to photo machined sheet stock.

Bright Nickel plating is often used as an undercoating to improve reflectivity and leveling to smooth out surface defects. Bright Nickel plate also provides an excellent barrier coating to reduce porosity and improve corrosion resistance. If an article is to be flexed, bent or distorted in the application, Sulfamate Nickel should be considered.

Request a quote for Sulfamate Nickel plating for your application, or contact us with any questions.

Sulfamate Nickel Process

Bright Nickel Process